Yaskawa Σ -V mini

Yaskawa Σ -V mini

The Σ -V mini, as its name suggests, inherits the high performance, high functionality and ease of operation of the Σ -V in the industry. It is a powerful servo the size of a finger.

Features

Pursue miniaturization

It can effectively utilize the limited space and reduce the volume of the control cabinet and machinery.

The flange dimensions of the motor

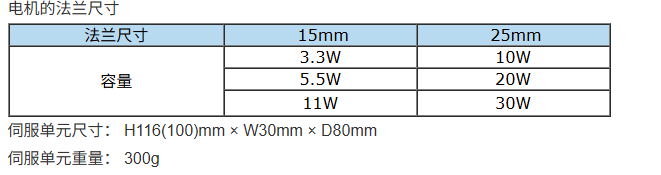

The flange size is 15mm to 25mm

Capacity: 33W - 10W

5.5W - 20W

11W 30W

Servo unit dimensions: H116(100)mm × W30mm × D80mm

Weight of the servo unit: 300g

Supports DC power input

The main circuit power supply is shared by DC24V and DC48V

The control power supply corresponds to DC24V, and the main circuit power supply can correspond to both DC24V and DC48V.

When the main circuit power supply uses DC48V, it can further enhance the motor's "torque-speed characteristic", thus being suitable for high-speed and high-frequency applications.

The extent to which the characteristics are improved varies depending on the motor.

It can be powered by a battery.

As a small, high-performance servo that can be powered by a battery, it can enhance mechanical performance when used in cleanroom robots and AGVs (unmanned transport vehicles), etc.

The control power supply is separated from the main circuit power supply system

The control power supply and the main circuit power supply system are separated

When an alarm occurs, only the power supply on the main circuit side can be cut off for fault maintenance.

Pursue high performance and convenient operation by applying the latest technology

Inheriting the high performance and convenient operation of ∑ -V!

It has the same speed-frequency responsiveness as the ∑ -V series (1.6kHz).

By applying the new advanced tuning function, servo adjustment that enables the equipment to achieve high-quality performance can be realized in a short time.

The product is also equipped with a new type of no-adjustment function, which is most suitable for: model tracking control function that shortens positioning time,

vibration suppression function that suppresses equipment vibration, friction compensation function with strong resistance to load changes, and applications where the equipment debugging operation time or load changes are large.

Achieve high-precision positioning and high-speed operation!

Equipped with a high-resolution 17-bit absolute value serial encoder (with an accuracy more than 16 times that of the previous product ∑-mini)

Through the parameter setting of the servo unit, it can be used as an incremental encoder

Achieving a maximum rotational speed of 6000min-1 is conducive to the high efficiency of the equipment

High-quality scalability

Corresponding to multiple instructions

Analog voltage, pulse sequence, MECHATROLINK-II communication, MECHATROLINK-III communication

Corresponding to various specifications (under development in sequence

CE marking, UL specification

.png)

.png)

.png)