GA700 Dedicated frequency converter for winding

GA700 Dedicated frequency converter for winding

The rich winding functions, combined with the reliable drive technology of Yaskawa frequency converters, can be applied to various winding equipment. To meet the diverse process requirements of customers, while ensuring the tension of materials, it makes the winding process simple, fast and perfect.

Features

In addition to the features of the standard GA700 frequency converter, the dedicated machine products also have the following functions:

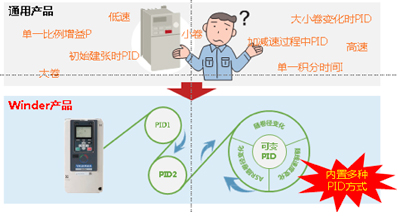

Rich PID functions

Compared with the single PID function of general-purpose frequency converters, dedicated machines have more than two sets of PID parameters.

Not only can it be switched through terminals, but also the linear adjustment of PID can be flexibly achieved according to process requirements, easily solving the tension control problems during tensioning, large and small rolls, and high and low speeds.

Perfect torque control

Compared with the simple torque control of general-purpose frequency converters, dedicated machines have a complete tension control system.

Whether it is the given tension or the internal torque conversion, there is no need for complex calculations by an external PLC. It automatically performs various torque compensations, well meeting the actual requirements of customers for winding and unwinding equipment.

Roll diameter calculation function

One of the core elements of tension control, similar to the mainstream practices in the market, is that the dedicated machine product calculates the current roll diameter size through the relationship between linear velocity and angular velocity, and converts the discrete signal into a continuously changing real roll diameter through variance sampling, providing convenience for subsequent tension control and monitoring.

Special function

· Tension taper curve

· Automatic roll changing function

· Material breakage detection function

· General/dedicated one-click switching function

· Consistent roll diameter detection function

.png)

.png)

.png)