Yaskawa V1000 small vector control frequency converter

Yaskawa V1000 small vector control frequency converter

Yaskawa frequency converters are highly praised for their high performance, high functionality and high quality.

Nowadays, the V1000 frequency converter, which pursues greater applicability and pays more attention to the convenience of use, has been born.

Features

Amazing!

The combined application with synchronous motors has achieved energy conservation, miniaturization and

Customized functions can provide you with various solutions.

1 multi-purpose unit (can also drive synchronous motors)

It can be applied to all kinds of motors. Besides induction motors (IM), it can also drive synchronous motors (IPMM, SPMM) that have previously been driven by dedicated frequency converters. Therefore, this frequency converter has strong versatility and realizes the generalization of frequency converter spare parts.

Outstanding torque characteristics

It is standard equipped with current vector control. It can achieve a high starting torque of 200%/ 0.5Hz * and also limit the torque. To fully leverage the motor's capabilities, it is also equipped with a self-learning function. No complicated debugging is required.

Enhance the braking capacity during deceleration

Over-excitation braking is adopted, which shortens the deceleration time.

Complete countermeasures for instantaneous power outages

The instantaneous power failure compensation function can be selected in terms of speed search mode and KEB mode according to the application. Both synchronous motors and induction motors are applicable.

■ Speed search mode

A motor in free operation can be started easily even without a speed sensor.

Customize the frequency converter according to your preferences

Equipped with the visual programming function DriveWorksEZ. By combining with the I/O of the upper-level control loop or frequency converter, the peripheral devices such as timers and relays that require peripheral equipment can be reduced. Using a computer, the frequency converter can be simply customized through drag-and-drop operations with the mouse.

Simple!

From setup to maintenance, the charm of the V1000 inverter can be felt everywhere.

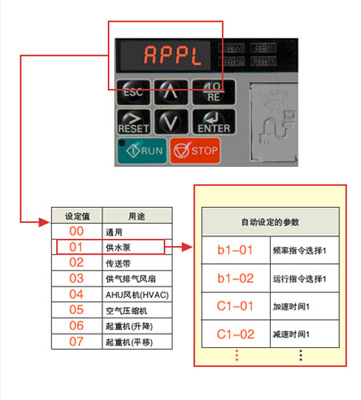

The frequency converter can be set according to its application!

Just select the uses such as the water supply pump, conveyor belt, air supply and exhaust fan, etc., and the appropriate parameters will be automatically set. The trial operation time has been shortened.

Multiple frequency converters can be easily set up using a copy unit with USB

The parameter setting content of the frequency converter can be simply copied to other frequency converters using a copy unit with USB (optional accessory). Connect the communication connector ON the inverter body with a dedicated cable. Just flip the ON/OFF switch on the copy unit, and the parameters can be easily copied.

With the help of computers, debugging and maintenance operations become more convenient

If the inverter engineering technology tool DriveWizard is used, the parameter setting values of multiple inverters can be managed uniformly by a computer. In addition, it is equipped with mode operation and oscilloscope functions, making the debugging and maintenance of the frequency converter much easier.

Comply with safety standards

It is standardly equipped with safety input functions that comply with EN954-1 Cat.3 and IEC/EN61508 SIL2. It can also reduce peripheral devices, thus easily meeting mechanical safety standards.

"Miniaturization!"

The compact frequency converter is equipped with high performance and multiple functions!

Smaller

By adopting thermal simulation technology and rationally arranging highly reliable components, miniaturization has been achieved. The volume has been reduced by up to 70% (compared with our previous products), and the structure is compact.

Set side by side

Multiple frequency converters can be set side by side without intervals, which can significantly reduce the size of the mechanical control cabinet.

(Note) In some cases, the load must be reduced

.png)

.png)

.png)