Industry-Specific Applications

The module finds application across multiple industries:

Oil & Gas: Wellhead control, pipeline operations, and processing facilities

Water/Wastewater: Pump control, chemical dosing, and flow regulation

Power Generation: Turbine control systems and auxiliary equipment

Manufacturing: Process temperature control and material flow regulation

Environmental Monitoring: Control of sampling and analysis equipment

Installation & Maintenance

Power Considerations: Ensure the system power supply can accommodate the additional load of the module

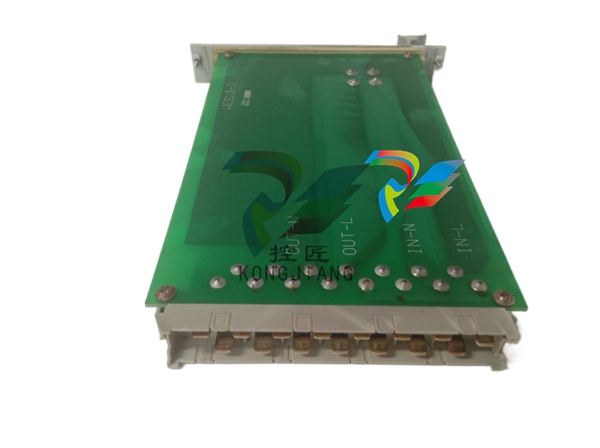

Mounting: Insert the module into an available slot in the ControlWave Micro chassis, ensuring proper alignment with the backplane connector

Wiring: Use shielded twisted-pair cables for analog signals, with shields grounded at one end only

Terminal Connections: Follow the specified pinout diagram, ensuring secure connections with proper torque on terminal screws

Grounding: Implement a proper grounding scheme to maintain isolation benefits and reduce noise

Cable Routing: Separate analog signal cables from power cables and sources of electromagnetic interference

Periodic Inspection: Visual inspection of module, connections, and indicators

Calibration Checks: Verification of output accuracy against known standards (recommended annually)

Firmware Updates: Application of any available firmware updates via ControlWave Designer software

Cleaning: Removal of dust and contaminants using dry, compressed air or soft brushes

Documentation: Maintenance of records for all inspections, calibrations, and repairs

Spare Parts: Keeping critical spares on hand to minimize downtime in case of failure

Troubleshooting Guide

| Symptom | Possible Causes | Recommended Action |

|---|---|---|

| No output on all channels | - Module not properly seated - System power issue - Module failure | - Check module insertion and backplane connection - Verify system power supply - Test module in another slot or system |

| No output on single channel | - Field wiring issue - Channel configuration - Channel failure | - Check field wiring connections - Verify channel configuration - Test with known good load |

| Inaccurate output values | - Calibration drift - Configuration error - Excessive load resistance | - Recalibrate module - Check scaling parameters - Verify load is within specifications |

| Unstable output signals | - Electrical noise - Grounding issues - Power supply fluctuations | - Improve shielding and routing - Check grounding scheme - Stabilize power supply |

| Module not recognized by system | - Software configuration - Incompatible firmware - Backplane communication issue | - Update system configuration - Check firmware compatibility - Test backplane with known good module |

Comparative Analysis

Understanding how the 396603-01-7 module compares to alternatives helps in making informed decisions for system design and upgrades.

| Model | Type | Points | Key Features | Best For |

|---|---|---|---|---|

| 396603-01-7 | Isolated AO | 4 | Channel-to-channel isolation, high precision | Critical control applications requiring isolation |

| 396603-02-5 | Remote AO | 4 | Remote mounting capability, extended distance operation | Distributed I/O configurations |

| 396353-01-0 | Local AO | 8 | Higher density, local mounting | Applications requiring more outputs in limited space |

| 396604-02-1 | Isolated AI | 8 | Input module with isolation, complementary to 396603-01-7 | Paired input/output systems requiring isolation |

Conclusion

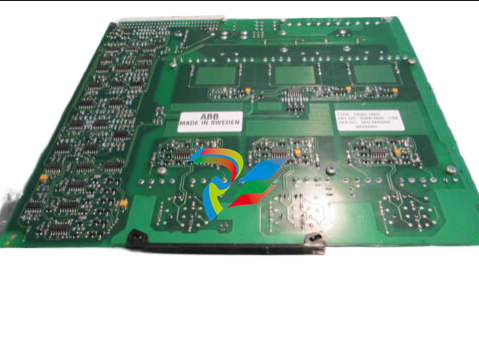

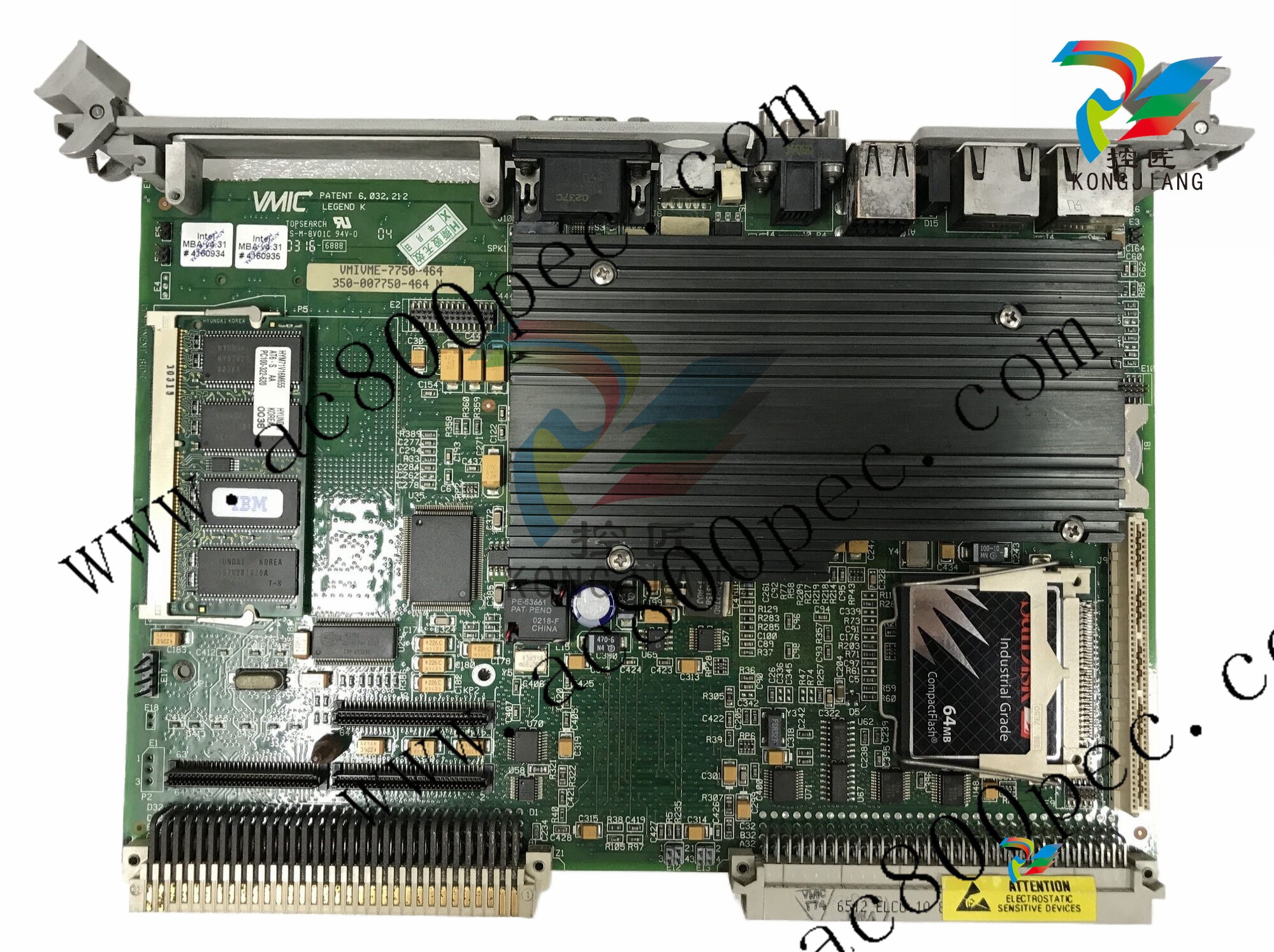

The Bristol Babcock ControlWave Micro 396603-01-7 Isolated Analog Output Module stands as a robust solution for applications requiring precise analog output control with electrical isolation. Its four-channel design balances channel density with signal integrity, making it particularly suitable for critical control applications in electrically challenging environments.

Key strengths include its comprehensive isolation scheme, high-precision output capability, and seamless integration with the ControlWave Micro platform. These features make it a valuable component in various industrial automation scenarios, particularly in process control, oil and gas, and utility applications.

For system integrators and maintenance personnel, understanding the module's technical characteristics, installation requirements, and troubleshooting procedures is essential for maximizing its performance and reliability in the field.

Contact for Technical Inquiry via WhatsApp