Product Overview

The Bristol Babcock ControlWave Micro 396603-01-7 is a specialized Isolated Analog Output Module designed for use with the ControlWave Micro automation platform. As an integral component of Emerson's industrial control systems portfolio, this module provides high-precision analog output capabilities with electrical isolation, making it suitable for demanding process control applications.

Technical Specifications

Basic Specifications

| Manufacturer | Bristol Babcock (Emerson) |

| Model | ControlWave Micro |

| Part Number | 396603-01-7 |

| Type | Isolated Analog Output Module |

| Form Factor | ControlWave Micro Compatible |

I/O Specifications

| Number of Channels | 4 points |

| Output Type | 4-20 mA (standard) |

| Resolution | 16-bit |

| Isolation | Channel-to-channel and channel-to-ground |

| Update Rate | 50 ms (typical) |

Electrical Specifications

| Supply Voltage | 24 VDC (from system) |

| Power Consumption | 3.5 W (typical) |

| Output Load | 0-750 Ω |

| Short Circuit Protection | Yes |

| Open Circuit Detection | Yes |

Environmental Specifications

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Vibration Resistance | IEC 60068-2-6 compliant |

| Shock Resistance | IEC 60068-2-27 compliant |

System Architecture & Integration

The 396603-01-7 Isolated Analog Output Module is designed to integrate seamlessly with the ControlWave Micro automation platform. Understanding its position within the broader system architecture is crucial for successful implementation.

System Components

The ControlWave Micro system typically consists of:

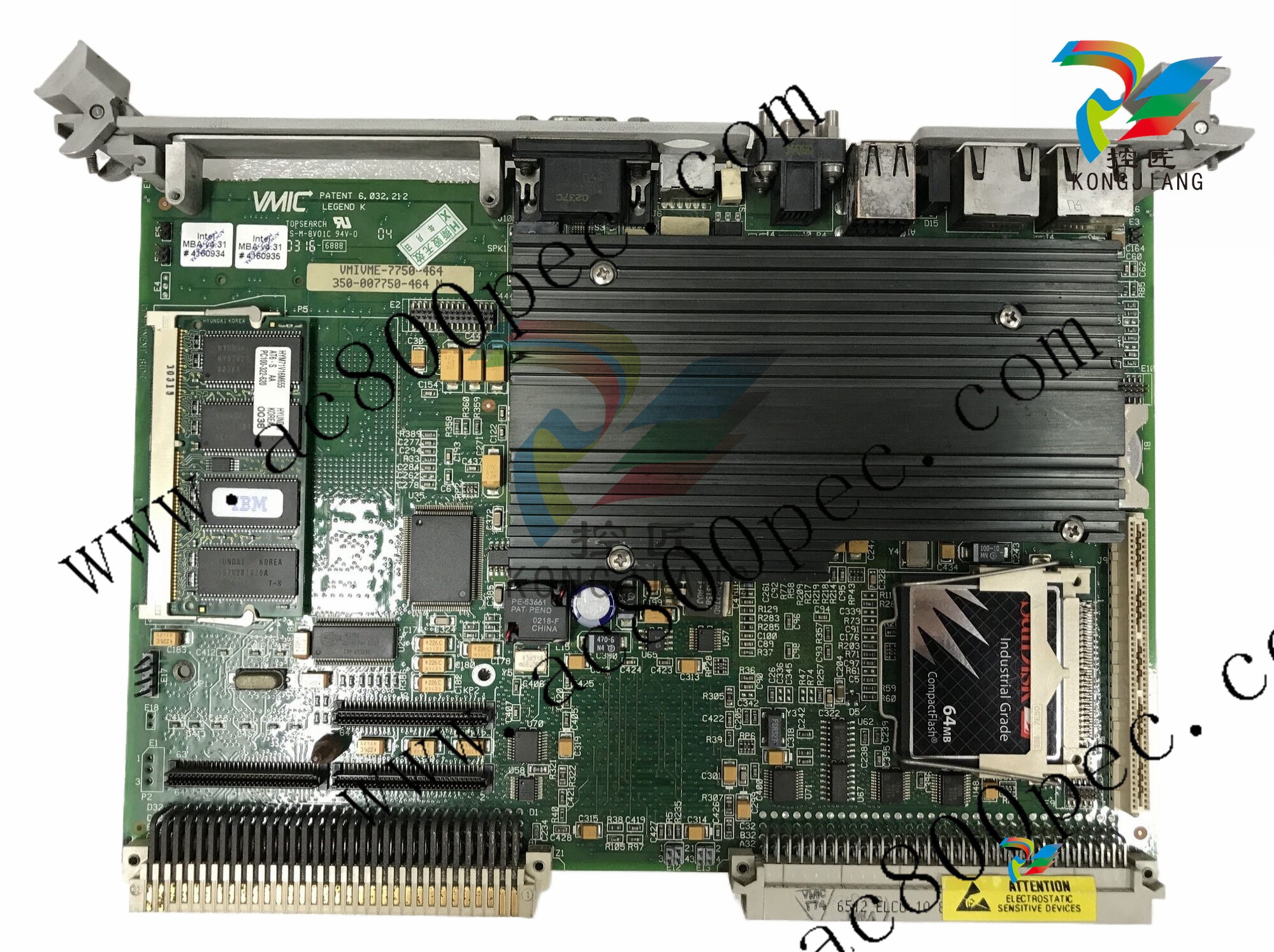

CPU Module (e.g., 396563 series)

Base Chassis (396560 series)

Power Supply Module (396657 series)

Various I/O Modules including:

Digital Input Modules

Digital Output Modules

Analog Input Modules

Analog Output Modules (396603 series)

Communication Interfaces

The 396603-01-7 module connects to the system via the backplane of the chassis, receiving power and communication through this interface.

Integration Methods

Integration of the 396603-01-7 module involves:

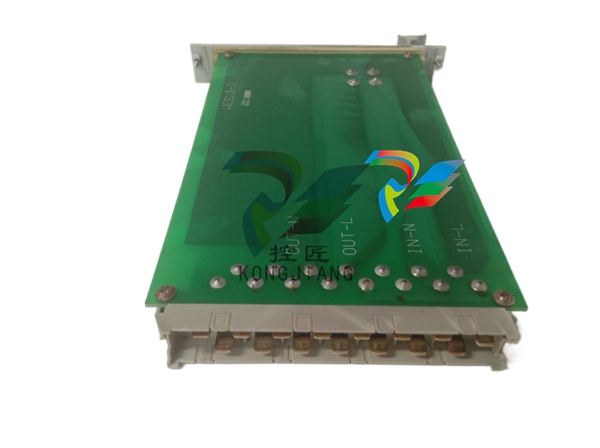

Physical Installation: Module insertion into an available slot in the ControlWave Micro chassis

Field Wiring: Connection of field devices to the module's terminals according to the specified pinout

Configuration: Setting up the module parameters using ControlWave Designer software

Calibration: Fine-tuning output signals to match field device requirements

Validation: Testing the complete signal path from controller to field device

Proper grounding and shielding of analog signal cables is essential for maintaining the isolation benefits of this module.

Functional Analysis

The 396603-01-7 module converts digital values from the controller into precise analog current outputs. Each channel operates independently with its own digital-to-analog converter (DAC) and isolation circuitry.

The signal processing flow includes:

Digital value reception from the controller (via backplane)

Digital filtering and scaling based on configuration parameters

Conversion to analog signals via high-precision 16-bit DACs

Signal conditioning and current output stage

Electrical isolation via optical or transformer-based isolators

Output driver circuits with protection mechanisms

This architecture ensures high accuracy and stability across the full operating temperature range while maintaining electrical isolation.

The isolation technology in the 396603-01-7 module is a critical feature that protects both the module and connected field devices from electrical disturbances. The module provides:

Channel-to-Channel Isolation: Each output channel is electrically isolated from other channels, preventing cross-channel interference

Channel-to-System Isolation: The output channels are isolated from the system's internal electronics, protecting the controller from field disturbances

Galvanic Isolation: Complete electrical separation using transformers or optocouplers to eliminate ground loops

Common Mode Rejection: High immunity to common mode voltages that may be present in industrial environments

This comprehensive isolation scheme makes the module suitable for applications in electrically noisy environments or where ground potential differences exist.

Application Scenarios

Process Control Applications

The 396603-01-7 module excels in process control applications requiring analog outputs:

Valve Positioning: Precise control of modulating control valves in fluid systems

Variable Frequency Drives: Speed control for motors in pumping or conveying systems

Pressure Regulation: Output signals to pressure controllers in gas or liquid systems

Temperature Control: Setpoint signals to temperature controllers in heating systems

Chemical Dosing: Control of metering pumps in water treatment or chemical processes