ABB ACS850 general-purpose frequency converter

give safety instructions for the installation, commissioning, operation and maintenance of the drive module.

Introduction to the manual introduces the manual

Operation principle and hardware description describes the drive module.

Planning the cabinet installation guides in planning drive cabinets and installing the drive module into a user-defined cabinet. The chapter gives cabinet layout examples and free space requirements around the module for cooling.

Planning the electrical installation instructs in the motor and cable selection, protections and cable routing

Installation describes how to install the drive module into a cabinet and connect the cables to the drive.

Start-up refers to the start-up instructions of the cabinet-installed drive

e. Fault tracing describes the LED indications and refers to the fault tracing instructions of the drive. Maintenance contains preventive maintenance instructions. Technical data contains the technical specifications of the drive module, eg, the ratings, sizes and technical requirements, provisions for fulfilling the requirements for CE and other markings. Dimension drawings contains dimension drawings of the drive module installed into a Rittal TS 8 cabinet. Example circuit diagram shows an example circuit diagram for a cabinet-installed drive module. Resistor braking describes how to select, protect and wire brake resistors. du/dt filters describes how to select du/dt filters for the drive. Categorization by frame size and option code The instructions, technical data and dimension drawings which concern only certain drive frame sizes are marked with the symbol of the frame size (G1 or G2). The frame size is marked on the type designation label. The instructions and technical data which concern only certain optional selections are marked with option codes, eg, +H381. The options included in the drive can be identified from the option codes visible on the type designation label. The option selections are listed in section Type designation key on page 35. Quick installation, commissioning and operating flowchart Task See Plan the installation. Check the ambient conditions, ratings, required cooling air flow, input power connection, compatibility of the motor, motor connection, and other technical data. Select the cables. Planning the cabinet installation (page 37) Planning the electrical installation (page 49) Technical data (page 125) Resistor braking (page 155) Option manual (if optional equipment is included) Unpack and check the units. Check that all necessary optional modules and equipment are present and correct. Only intact units may be started up. Moving and unpacking the unit (page 74) Checking the delivery (page 76) If the drive module has been non-operational for more than one year, the converter DC link capacitors need to be reformed. (Reforming the capacitors, page 12

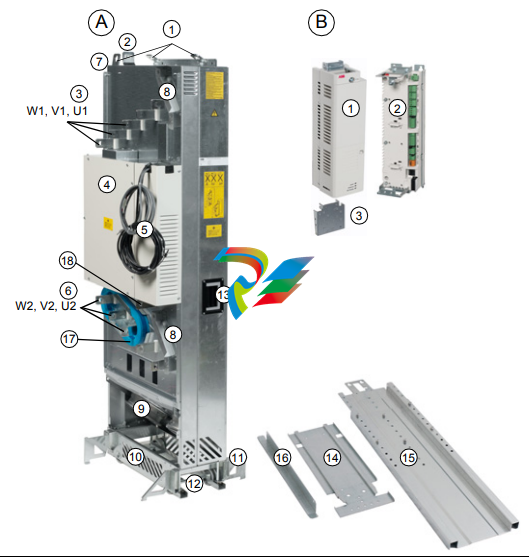

Item Description A Drive module 1 Lifting lugs 2 Fastening bracket 3 Input cable connection busbars and optional DC+ and DC- busbars (+H356) 4 Circuit board compartment 5 Power supply and fiber optic cables to be connected to the external control unit 6 Output cable connection busbars and optional brake resistor connection busbars (+D150) 7 PE terminal 8 Control cable duct 9 Main cooling fans 10 Pedestal 11 Retractable support legs

Item Description

12 Base fastening screws 13 Handle for pulling the drive module out of the cabinet 14 Pedestal guide plate 15 Telescopic extraction and insertion ramp 16 Top guide plate 17 Optional common mode filter (+E208) 18 Grounding busbar B Control unit (JCU) 1 Control unit with front cover 2 Control unit with front cover removed 3 Control cable clamp plate

Resistor braking

What this chapter contains This chapter describes how to select, protect and wire brake resistors. Availability of brake choppers and resistors Brake choppers are optionally available as built-in units, indicated in the type description by +D150. External resistors are available on request from ABB. When is resistor braking needed Typically, a drive system is equipped with brake choppers and resistors if: • high capacity braking is needed and the drive cannot be equipped with a regenerative supply unit • a backup for the regenerative supply unit is needed. Operation principle The energy generated by the motor during a fast deceleration of the drive typically causes the voltage to rise in the drive module intermediate DC circuit. The chopper connects the brake resistor to the intermediate DC circuit whenever the voltage in the circuit exceeds its maximum limit. Energy consumption by the resistor losses lowers the voltage until the resistor can be disconnected. Planning the braking system Selecting the brake circuit components 1. Calculate the maximum power (Pmax) generated by the motor during braking. 2. Select a suitable drive and brake resistor combination for the application according to the rating table on page 159. Take also account of other factors in the drive selection. The braking power must be greater than or equal to the maximum power generated by the motor during braking: 3. Check the resistor selection. The energy generated by the motor during a 400- second period must not exceed the resistor heat dissipation capacity ER. Note: If the ER value is not sufficient, it is possible to use a four-resistor assembly in which two standard resistors are connected in parallel, two in series. The ER value of the four-resistor assembly is four times the value specified for the standard resisto

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)