Bently3300 XL 8mm Proximity Transducer System

5 mm and 8 mm components. Although the packaging of the 3300 XL Proximitor Sensor differs from its predecessor, its design fits in the same 4-hole mounting pattern when used with the 4-hole mounting base, and will fit within the same mounting space specifications (when minimum permissible cable bend radius is observed).

5. Mixing XL and non-XL 3300-series 5 mm and 8 mm system components limits system performance to the specifications for the non-XL 3300 5 mm and 8 mm Transducer System.

6. The 3300-series 5 mm probe (refer to Specifications and Ordering Information p/n 141605-01) uses smaller physical packaging, but does not reduce the side view clearances or tip-to-tip spacing requirements as compared to an 8 mm probe. It is used when physical (not electrical) constraints preclude the use of an 8 mm probe. When your application requires narrow side view probes, use the 3300 NSv* Proximity Transducer System (refer to Specifications and Ordering Information p/n 147385- 01).

7. 8 mm probes provide a thicker encapsulation of the probe coil in the molded PPS plastic probe tip. This results in a more rugged probe. The larger diameter of the probe body also provides a stronger, more robust case. We recommend that you use 8 mm probes when possible to provide optimal robustness against physical abuse.

8. Each 3300 XL extension cable includes silicone tape that you can use instead of connector protectors. We do not recommend silicone tape for applications that will expose the probe-to-extension cable connection to turbine oil.

Specifications Unless otherwise noted, the following specifications are for a 3300 XL 8 mm Proximitor Sensor, extension cable and 8 mm probe between +18 C and +27

C (+64 F to +80 F), with a -24 Vdc power supply, a 10 kΩ load, an AISI 4140 steel target, and a probe gapped at 1.27 mm (50 mils). Performance characteristics apply to systems that consist solely of 3300 XL 8 mm components. The system accuracy and interchangeability specifications do not apply to transducer systems that are calibrated to any target other than our AISI 4140 steel target.

Electrical Proximitor Sensor Input

Accepts one non-contacting 3300-series 5 mm, 3300 8 mm or 3300 XL 8 mm Proximity Probe and Extension Cable.

Power

Requires -17.5 Vdc to -26 Vdc without barriers at 12 mA maximum consumption, -23 Vdc to -26 Vdc with barriers. Operation at a more positive voltage than -23.5 Vdc can result in reduced linear range

Supply Sensitivity

Less than 2 mV change in output voltage per volt change in input voltage.

Output Resistanc

50

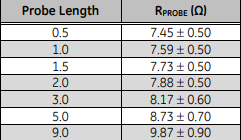

Nominal Probe DC Resistance

Resistance (RPROBE) from Center Conductor to Outer Conductor

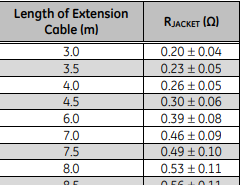

Nominal Extension Cable DC Resistance

Resistance (RCORE) from Center Conductor to Center Conductor

Hazardous Area Conditions of Safe Use:

CSA/NRTL/C: ia:Install per Bently Nevada drawing 141092.

nA:

Install per Bently Nevada drawing 140979.

ATEX/IECEx: ia:

The Prox must be installed so as to minimize the risk of impact or friction with other metallic surfaces.

nA:

The Prox must be installed so as to provide the terminals with a degree of protection of at least IP54

Mechanical Probe Tip Material

Polyphenylene sulfide (PPS)

Probe Case Material

AISI 303 or 304 stainless steel (SST).

Probe Cable Specifications

Standard cable:

75Ω triaxial, fluoroethylene propylene (FEP) insulated probe cable in the following total probe lengths: 0.5, 1, 1.5, 2, 3, 5, or 9 metres.

Extended Temperature Range cable:

75Ω triaxial, perfluoroalkoxy (PFA) insulated probe cable in the following total probe lengths: 0.5, 1, 1.5, 2, 5, or 9 metres.

Armor (optional on both):

Flexible AISI 302 or 304 SST with FEP outer jacket.

Tensile Strength (Maximum Rated):

330 N (75 lbf) probe case to probe lead. 270 N (60 lbf) at probe lead to extension cable connectors.

Connector Material

Gold-plated brass or gold-plated beryllium copper.

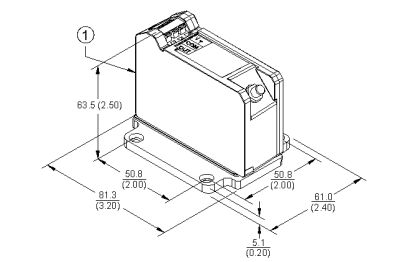

. Mounting option “A”, Options –50 or -90.

Figure 19: Panel Mount 3300 XL Proximitor Sensor

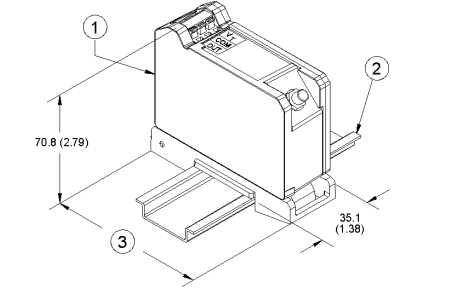

1. Mounting option “A”, Options –51 or –91 2. 35mm DIN rail (not included) 3. 89.4 mm (3.52 in). Additional 3.05 mm (0.120 in) clearance required to remove DIN rail.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)