BentlyBlocking and Test System Instruction Manual

Introduction The GE Multilin 515 Blocking and Test Module has the following features:

• 14 Pole switchbank

• CT inputs short when current switches are opened

• Current injection for each phase • Ground terminal

• Ability to visually isolate (open) trip relay output circuits

• Cover provided • Suitable for utility and industrial use

• 515 test plugs available

Description

The 515 Blocking and Test Module provides an effective means of trip blocking, relay isolation and testing of GE Multilin relays. By opening the switches and inserting test plugs, phase and residual currents from the primary CTs can be monitored. Currents can be injected into the relay from a secondary injection test set during commissioning. Prior to testing, the trip and auxiliary circuits must first be opened to prevent nuisance tripping; CTs can then be shorted. Conversely, when the test is complete and the relay put back into operation, the CT switches should be closed first to ensure normal operation of the relay, prior to closing the trip and auxiliary circuits

Installation

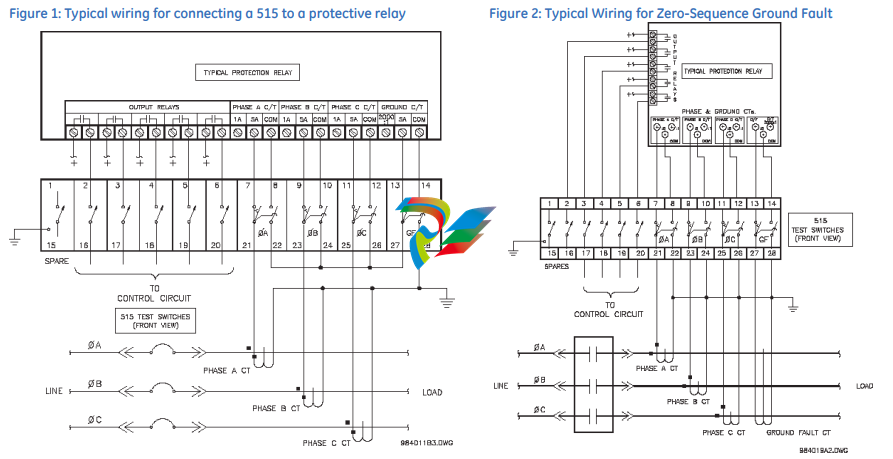

Shorting switches are provided for connection of 3 phase CTs (current transformers) and a separate core balance ground fault CT or 3 phase CTs connected for residual ground fault sensing. When each CT switch is opened, the CT is shorted. It is essential that the CT is connected to the shorted side of the switch as shown in the following figure, otherwise dangerously high voltages would be present from the open circuited CTs. When the switches are open, test plugs can be inserted to either inject signals into the relay wired to the switches or monitor signals such as CT current from the switchgear

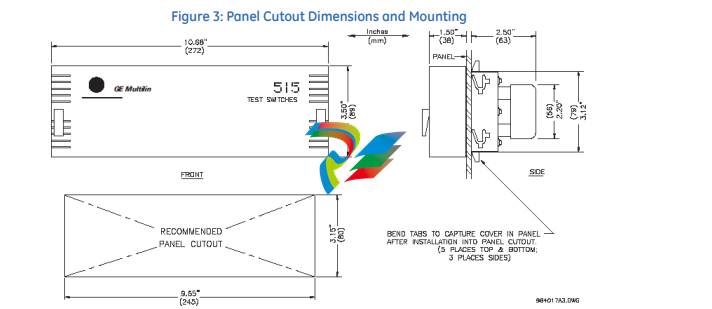

The 515 Blocking and Test Module consists of a metal chassis attached to the 515 test switches that slides into the panel. A single cutout in the panel, as per the dimensions shown in Figure 3, is required to mount the 515 test switches.

Slide the metal chassis attached to the 515 test switches into the cutout from the front of the panel. While firmly applying pressure from the front of the 515 module to ensure the chassis fits snugly, bend out the retaining tabs as shown in Figure 3. Usually the retaining tabs will be sufficient to hold the 515 module securely in place. If additional fastening is desired bend out the clamping screw tabs at both ends of the chassis at right angles. Insert the #8 screws provided in the accessory pouch into the tapped holes with the vibration proof nut between the tab and the panel. Tighten each screw until the end of the screw butts firmly against the front panel. Ensure the nut

is installed tightly against the bent tab. Nylon inserts in these nuts prevent them from vibrating loose. The 515 test switch module should now be securely mounted to the panel with no movement ready for rear terminal wiring. When completed, place the front cover over the mounted 515 test module and turn the fasteners at both ends ¼ turn to lock it in place, as shown in Figure 3. As a safety precaution, a ground screw located on the bottom-right of the rear side of the module is available to be connected to panel chassis ground.• 1 package containing at least 28 terminal nuts

• 14 white tags for identification of each of the switches

The 515 provides a means of trip blocking, relay isolation, and testing of GE Multilin relays. The 515 accomplishes this with a total of 14 switches. There are 6 single pole throw switches for use with the output relays, and 4 groups of 2 switches each for use with the current transformers as illustrated in Figure 1: Typical Wiring. Isolation or opening of the relay’s output circuits is accomplished with the six switches at terminals 1 through 6 and 15 through 20. These switches can be used to simply open the protection relay's output contacts and thus provide a means of blocking trips. The 4 remaining groups of 2 switches at terminals 7 through 14 and 21 through 28 are used for shorting of the CT inputs, injection of test current, and measuring of CT current. The four groups correspond to Phase 1 Current, Phase 2 Current, Phase 3 Current, and Ground Current. Each group is made up of two switches. The first switch for the Phase 1 group is at terminal 7 and 21 and is configured as shown on the right: Note that terminals 7 and 21 are shorted together regardless of whether the switch is open or closed. The second switch for the Phase 1 group is at terminals 8 and 22. It is configured as shown on the right: Note that this switch operates as make before break. When this switch is closed terminals 8 and 22 are shorted together. When this switch is open, terminals 8 and 22 open and 22 shorts with 7 and 21. This in turn shorts the Phase 1 CT. It is essential that the CT is connected to the shorted side of the switch as shown on the right. Otherwise, dangerously high voltages would be present at the open circuited current transformer. Also note that currents can be injected into the protection relay from a secondary injection test set. With the switch between terminals 7 and 21 open and the switch between terminals 8 and 22 closed as shown below, a 515 test plug can be inserted between terminals 7 and 21 to monitor the CT current. See the diagrams below for details. Note that the 515 test plug is made up of two conductors separated by an insulator.

.png)

.png)