Bently3500 System Overview

Description The 3500 System provides continuous, online monitoring suitable for machinery protection applications, and is designed to fully meet the requirements of the American Petroleum Institute’s API 670 standard for such systems. It represents our most capable and flexible system in a traditional rack-based design, and represents numerous features and advantages not provided in other systems. The system’s highly modular design consists of:

• 3500/05 Instrument Rack (required)

• One or two 3500/15 Power Supplies (required)

• 3500/22M Transient Data Interface or 3500/20 Rack Interface Module (required) • One or two 3500/25 Keyphasor® Modules (optional) • 3500 Rack Configuration Software (required)

• One or more 3500/XX Monitor Modules (required)

• One or more 3500/32 Relay Modules or 3500/34 TMR Relay Modules (optional) • One or more 3500/92 Communication Gateway Modules (optional)

• 3500/93, 3500/94, or 3500/95 display OR 3500 Operator Display Software running on a compatible PC (optional)

• Internal or external intrinsic safety barriers, or galvanic isolators for hazardous area installations (optional) These are described in more detail in the following section and in the individual datasheets for each system component.

System Components

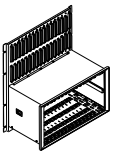

Rack The full-size 3500 Rack is available in 19” EIA railmount, panel-cutout-mount, and bulkhead-mount versions. The rack provides slots for two Power Supplies and a Rack Interface Module in the left-most rack positions that are reserved exclusively for these modules. The remaining 14 slots in the rack can accommodate any combination of monitor, display, relay, Keyphasor module, and communications gateway modules. All modules plug into the rack’s backplane and consist of a main module and an associated I/O module. The I/O module installs at the rear of the rack for panel-mount systems, and above the main module for bulkhead-mount systems. The rack depth is 349 mm (13.75 inches) and NEMA 4 and 4X weatherproof housings are available when required for environmental protection or when purge air is used. A mini-rack (12” wide instead of 19”) is also available and features 7 available monitor slots instead of 14. Like its larger counterpart, the left-most slots are reserved for the Power Supply or Supplies and Rack Interface Module. The mini-rack may be mounted in a panel cutout or, using an optional adapter plate, on 19” EIA mounting rails. Bulkhead mounting is not available.

Power Supply

The 3500/15 Power Supply can be ordered for ac or dc input power, providing compatibility with voltage sources worldwide. Line noise filters are standard. The 3500 Rack can operate from a single supply, or dual Power Supplies can provide redundancy for situations which cannot tolerate power interruption. Dual supplies reside in the upper and lower positions of the left-most rack slot. Redundant Power Supplies can use with separate voltage sources. For example, the primary (bottom) supply can be operate with 120 Vac power while the backup (upper) supply can be powered from an uninterruptible 24 Vdc source. Each Power Supply can individually provide power to the entire rack and its modules. When redundant supplies are used, one supply acts as primary power for the rack while the other acts as a backup, ready to instantly and automatically operate as the primary rack supply without interrupting rack functions., should the primary supply fail. The 3500/15 Power Supply module has selfmonitoring functions that allow it to determine if all its output voltages are within specifications. The module annunciates this via a green “Supply OK” LED on the Power Supply’s front panel.

Rack Interface Module/Transient Data Interface

The Transient Data Interface (TDI) or the Rack Interface Module (RIM) are the 3500 Rack’s primary interfaces to the configuration, display, and condition monitoring software. Each rack requireas one TDI or RIM, which resides in the rack slot immediately adjacent to the Power Supply slot. The TDI and RIM support a proprietary protocol used by both the 3500 Configuration Software to configure the rack and the 3500 Operator Display Software to retrieve rack data and statuses. TDI provides a direct interface with GE’s Bently Nevada System 1® machinery management software without the need for an external communications processor. The RIM requires an external communications processor, such as TDXnet™, TDIX, or DDIX to interface to Data Manager® condition monitoring software. The System OK relay1 is located within the TDI/RIM’s I/O module. It is driven by NOT OK conditions within the TDI/RIM itself and within other modules in the rack.

The TDI and RIM supply “self monitoring” functions both for themselves and for the rack, in addition to those provided by the individual monitor, relay, communications, and other modules. While the TDI and RIM provide certain functions common to the entire rack, neither is part of the critical monitoring path and has no effect on the proper, normal operation of the overall 3500 System or its machinery protection functions. The TDI and RIM provide 4 front-panel LEDs as follows:

.png)

.png)

.png)