HarmonicHarmonic Drive™ servo

and at power supply after disconnecting the cable between the driver and the encoder for a long duration.

To recover the alarm, input the multi-turn data clear signal at least 4 seconds, and shut off the control

power once and turn it on again.

◆ ABS MTD overflow (54)

For the absolute encoder, the alarm occurs when the count for multi-turn data (MTD) goes beyond the

range of +4095 to - 4096 turns (motor axis). To recover the alarm, input the multi-turn data clear signal at

least 4 seconds, and shut off the control power once and turn it on again.

◆ ABS multi-turn data error (55)

For the absolute encoder, during an energy-saving mode, where no power by power supply but the

encoder circuit is active only by the power of a built-in condenser and a built-in battery, the alarm occurs

when the encoder rotates too fast at the acceleration rate and speed exceeding the recording ability of

the multi-turn counter on the mode. To recover the alarm, input the multi-turn data clear signal at least 4

seconds, and shut off the control power once and turn it on again.

◆ ABS low battery voltage (56)

For the absolute encoder, when voltage of the built-in battery is low. To recover the alarm, change the

battery for a new one, and shut off the control power once and turn it on again.

◆ ABS send data rule error (57)

The absolute encoder rotates more than 127 resolvable pulses by external torque during transmitting

absolute data. To recover the alarm, shut off the control power once and turn it on again.

◆ Error counter overflow (60)

The alarm occurs when an error count exceeds the set value in [parameter mode]→[6: position error

allowance]. It is possible to clear the alarm by inputting a signal to [CN2-2 clear: CLEAR]. The error

count is cleared at the same time.

◆ Memory failure (RAM) (70)

The alarm occurs when the driver’s RAM memory fails. It is impossible to clear the alarm.

◆ Memory failure (EEPROM) (71)

The alarm occurs when the driver’s EEROM memory fails. It is impossible to clear the alarm.

◆ CPU failure (76)

The alarm occurs when the driver’s CPU fails. It is impossible to clear the alarm.

Chapter 2 Functions

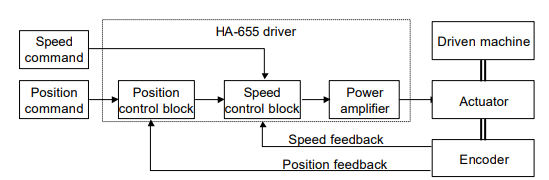

2-1 Control system of the HA-655 driver

It is said that [plan, do, see] is essential to perform perfect

jobs. In other words, the [plan, do, see] is the repeating

cycle of command→action→result→feedback→modified

command → action → feedback →・・・・ .

Driving machines precisely requires the same control as

the above job cycle, that is [Motion command→run→

feedback→modified command→・・・・].

For example, assume the required motion is rotation to a

target angle and stopping there. To perform the motion,

the motor must be equipped with an angular sensor to

detect a current position, and the position data must be

compared with the command. If the position data is

different than the command, the motor rotates until the

position data becomes equal to the command. This is an

example of a position servo system.

The speed control system is the same. The motor is

equipped with a speed sensor and the speed is compared

with the speed command. If the speed is different from the

command, the motor accelerates or decelerates until the

motor speed becomes equal to the command. This is an

example of the speed servo system.

The HA-655 driver realizes above both controls of position and speed with the same unit.

The fundamental configuration of servo system of the HA-655 driver is as follows:

The HA-655 driver function is consists of three parts: the position control block, the speed control block,

and the power amplifier.

In the position mode, a command position from a host is compared to a feedback position. If there is a

difference between them, the position control block commands the power amplifier through the speed

control block to flow current to the actuator until there is no difference.

In the speed mode, a speed command is directly inputted to the speed control block. The speed block

compares the command and current feedback speed. If there is a difference between them, the speed

control block commands to the power amplifier flow the current to the actuator until there is no

difference.

The HA-655 driver allows two types of encoder as a functional member of the feedback system,

optionally: an incremental encoder or an absolute encoder.

2-2 Position mode

The HA-655 driver makes use of either the position control or the speed control. This section describes

the position mode. (※ The default setting is the [position mode].)

Before driving, set the control mode by [parameter mode] → [0: control mode].

2-2-1 Command configuration in position mode

In the position mode, the command is transmitted from a host in the form of a digital pulse signal train.

The HA-655 driver provides two pair of two ports (CN2-27&28, CN2-29&30) for the command pulses.

Signals of three type of configurations are available for the ports.

● Setting a command configuration

[Parameter mode]→[1: command configuration]

● Relating I/O pins

Input pins: CN2-26 to 30

.png)

.png)

.png)