HarmonicHarmonic Drive™ servo

(1) 2-pulse train (FWD and REV pulse train)

Two pairs of two terminals are provided, and each of FWD and REV pulse trains is assigned a pair

independently. FWD commands and REV commands are inputted in the pair of FWD ports and REV

ports respectively, as shown in the figure below. When signals are inputted to a pair of terminals, the

signal to the other should keep [OFF] state.

(2) 1-pulse train (polarity + pulse train)

One pair of terminals is assigned dedicatedly for command pulse train, and the other is assigned to a

sign for rotary direction. Position commands are inputted in the FWD port pair only and the REV port pair

accepts the sign of rotary direction, as shown in the figure below. [OFF] or [Low level] state is for the

FWD command and [ON] or [High] level is for the REV command.

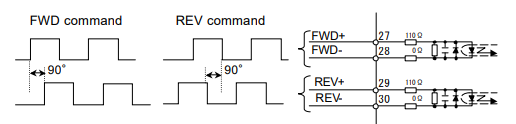

2-phase pulse train (A-B phase pulses with 90 degree difference)

Both port pairs receive the command pulse trains that have a 90 electric degree difference relative to

each other as shown in the figure below. For the FWD command, the pulse train to the FWD ports

advances 90 degrees from the REV port train. For the REV command, the REV port train advances from

the FWD port train.

The encoder pulse trains to the driver have this 2-phase pulse configuration

◆ Multiplication of command

When the command configuration is a

[2-phase pulse] type, it is possible to multiply

the command pulse train by 2 or 4 for the

command pulse train to an actuator.

The encoder feedback pulse train is

quadrupled.

● Setting

[Parameter mode] → [2: multiplication of

2-phase pulse]

◆ Electronic gear

The electronic gear function can be set make a given

displacement of the driven mechanism for one

command pulse, an integer, or a convenient number.

For example, it is convenient to set the displacement of

0.1 micrometer for one pulse as shown in figure to the

right.

The function multiples the command pulse count by the

coefficient (fraction).

The relation of [denominator / numerator] of the coefficient

is obtained as follows:

2-2-2 Command transmitting system

Two systems are provided for transmitting command pulses: [open collector] and [line driver].

◆ Open collector system

This system employs a transistor whose emitter is

common and whose collector is open. Since the

output signal is voltage type, this system is

unsuitable for long distance transmission due to line

voltage drop.

◆ Line driver system

The line driver system conforms to (EIA) RS-422

standard providing line drivers for transmitting

signal pulses. Since the output signal is current type,

this system is suitable for long distance

transmissions without attenuation of signals.

Furthermore, the line driver system transmits data

faster than the open collector system.

2-2-3 Outputting encoder signals

Two kinds of encoder are selectable for the FHA-C

series actuator: incremental or absolute. The

incremental encoder feeds back two pulse-trains

into the HA-655 driver as shown in the figure to the

right. The pulse trains are called [phase-A] and

[phase-B]. For the encoder resolution, refer to

actuator’s technical manual.

On the other hand, the absolute encoder feeds back

a combination of absolute signals and two

pulse-train signals.

In addition to the 2-phase pulse trains, both

encoders output a [phase-Z] pulse signal once per

motor rotation for use as an origin. The pulse signal

is sometimes called [phase-C] or [index].

The HA-655 driver outputs encoder signals using a

line driver system. The signals can be received by a

line receiver: AM26LS32 (EIA-422A) or equivalent.

Phase-Z signal is also available (open collector

output {CN-42 pin}).

The phase-Z signal is asynchronous.

Three encoder signals mentioned above are

available for a host.

● Relating I/O pins

Output pins: CN2-42 to 49

2-2-4 Absolute encoder signals

u General descriptions and functions of absolute encoders

The absolute encoder housed in a FHA-C series actuator provides an absolute sensor to generate an

absolute pulse train for a resolvable position (the sensor is herein after referred to as “single-turn

encoder”.), and an electronic counter to generate an absolute pulse train for a revolution of the motor

(the counter is hereinafter referred to as “multi-turn counter”.).

An absolute position of the encoder is kept in the memory, which is always energized by a combination

of the built-in condenser in the actuator and the backup battery housed in the HA-655 driver.

Please interpret that “single-turn” and “multi-turn” in the manual mean one and plural revolutions of the

encoder (the motor) in an actuator, respectively. Therefore, the actual actuator resolvable position of

either “single-turn” or “multi-turn” can be obtained by multiplying an absolute pulse train of the single-turn

encoder and the multi-turn counter by a reduction ratio of the actuator.

u Single-turn absolute encoder

The single-turn encoder is composed of an encoder disk, an LED light source, and a photo-detector. The

single-turn absolute encoder system outputs a current absolute pulse train combined with an absolute

.png)

.png)

.png)