ABBIndustrial Networks Connecting Controllers via OPC

all float variables were set to exactly the same value, being increased by one at

every cycle and sent from one controller to the other. On this receiver side, the

range between the maximum and minimum value are identified. If the range is

small, integrity is good. If the range is wide, this shows that some variables do not

change at the same time and therefore are not transmitted correctly.

4.4.3 Availability

To get an idea about the availability of such a system, one configuration was running for one week (seven times 24 hours). The goal of this evaluation was to find

out about the capability to run the system for a longer period or if it fails after some

hours. Furthermore, the two preceding measurements are included with recording

the average and maximum RTT as well as average and maximum integrity check

range. Due to time limitation this availability long-time test was only performed

using the Woodhead PROFIBUS approach and a realistic variable quantity according to Test 4 Configuration B. In order not to impair the measurement and falsify

results, we abandoned a more detailed logging.

While numerical information on availability of industrial devices it based upon

extensive tests and long-time information, this was not within the scope of our

thesis. A mathematical approach cannot be performed either, due to the lack of

numerical information of the single parts in the personal computer.

Chapter 5

Results

In this chapter we will present and discuss the results gained from our evalutations.

5.1 Bridging Software

We started the evaluation using Matrikon’s OPC Data Manager. Unfortunately,

the behavior of the GUI was sometimes unsatisfying, particularly due to its long

delays. Additionally, the communication stopped at times for unknown reasons.

The equivalent product LinkMaster from Kepware offers similar possibilities in

configuration but did not show these effects. Furthermore, the performance of

LinkMaster could be determined as being vastly better than the one of ODM:

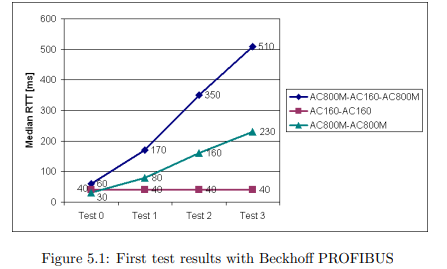

For Test 3 with Beckhoff PROFIBUS the median RTT with LinkMaster is 510

milliseconds, whereas with ODM and the same preconditions the RTT becomes

more than ten times slower. As a consequence, all main tests were performed

using Kepware’s LinkMaster software. For some configurations we enabled a device

refresh rate of 10 ms for only one group in each direction, which prevented the

program from unwanted stopping.

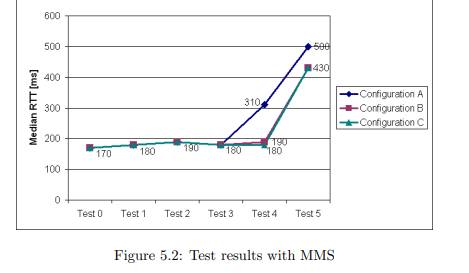

5.2 Round-Trip Times

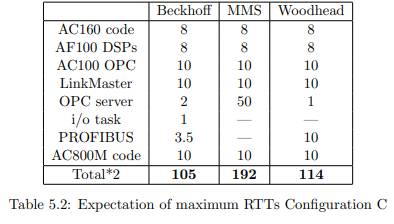

This section shows the results for the round-trip time tests, grouped by test system variations. In Table 5.2 we show the expected maximum RTTs based on the

addition of cycle times and update rates.

Test 1 Test 2 Test 3 Test 4 Test 5

2.7 ms 3.2 ms 3.5 ms 7 ms 10 ms

Table 5.1: Rounded PROFIBUS cycle time measurements

For the PROFIBUS cycle times we entered the maximum values measured with

CI854A shown in Table 5.1, Test 3 for the Beckhoff setup and Test 5 for Woodhead

approach. The configuration of the PROFIBUS parameters was done automatically

by AC800M with “actual value based” method for all test we performed.

5.2.1 System 1: Beckhoff PROFIBUS

Evaluations were performed for different amounts of signals as defined in Table 4.1.

Starting with the Beckhoff PROFIBUS solution, we could observe that the RTT

increases linearly to the amount of signals. While test results with one single signal

(Test 0) were promising, the following tests were already unacceptable, although

defining only a fraction of the required amount of variables.

After short-circuiting the connections it was quickly determined that the bottleneck is to be found in the writing to the AC800M. After inspecting the LinkMaster

software and PROFIBUS configuration the bottleneck was isolated as the OPC

server to PCI card communication. Interrogating Beckhoff support confirmed this

suspicion: Since it is much more common to read from OPC servers, the reading

process was optimized by transporting several values in block mode from the PCI

card to the OPC server, using Beckhoff’s own ADS protocol. In contrary, values

written to the OPC server are transmitted one by one [34]. This explains our results, and after putting into operation two more clone OPC servers, which is the

maximum number, the RTT expectedly was more or less three times lower. However, with 190 ms median RTT for Test 3 and added configuration effort, this is

still not satisfactory. It is to add that Beckhoff offers a nice and sophisticated configuration tool, which also allows the swapping of words and bytes. This function

is used when processing float values which are interpreted different in FC3102 PCI

card than in CI854A.

After these findings it was inevitable to look for another solution, also keeping

thoughts in mind that it would be necessary—due to the 244 byte limitation—to

put six FC3102 PCI cards into a computer in order to have enough capacity for

all required values, or alternatively to have eleven DP/DP-couplers at work1

. The

idea to “multiplex” data over the PROFIBUS in order to defuse byte limitation was

discarded as impracticable.

5.2.2 System 2: MMS

Before looking at the results, it is to mention that, compared with the PROFIBUS

solution, the MMS approach suffers from vast disadvantages: Firstly, the maximum