ABBIndustrial Networks Connecting Controllers via OPC

the performance is considered to be very small compared to the other parts.

3.5.1 System 1: Beckhoff PROFIBUS

Figure 3.7 shows the schematic setup for the Beckhoff PROFIBUS approach. It

is to mention that Beckhoff uses their proprietary ADS protocol to communicate

between the OPC server and the card driver, which was therefore outlined in this

figure [20]. The maximum update rate of TwinCat OPC Server is 2 milliseconds,

the cycle time of the variable i/o task is 1 ms.

Figure 3.7: Schematic setup of Beckhoff PROFIBUS approach

3.5.2 System 2: MMS

The MMS approach is depicted in Figure 3.8. In contrary to the PROFIBUS

solution there is no need for an additional communication device connected to

CEX bus as the Ethernet port is located in the processor module itself, using its

resources. Unfortunately, the maximum update rate of the AC800M OPC Server

is limited to 50 milliseconds, which is a comparatively high value compared to the

cycle time of other system parts.

3.5.3 System 3: Woodhead PROFIBUS

In contrary to Beckhoff’s solution, Woodhead implements a more direct access path

for the OPC server. Its maximum update rate is 1 millisecond. The GSD-file of

the SST-PBMS-PCI card had to be slightly modified in order to be importable by

Control Builder M. Furthermore, there exists a trick how to simplify bulk setup of

OPC tag names. More information on the latter as well as a working GSD-file is

enclosed with the CD-ROM in the appendix.

Chapter 4

Evaluation

In this chapter we describe the evaluations performed on the test system. In order

to implement the different tests, we needed to program both controllers with appropriate code, which presumed the know-how for two quite different application

development systems and engineering tools (see [30], [31], [32] and [33]).

4.1 Test Systems

As described in the preceding chapter, we evaluated three different test system

variants. While the AC160 side physically stayed the same for all tests, the AC800

connection was tested with the following approaches:

• PROFIBUS connection with Beckhoff’s card and server

• Standard MMS connection using an Ethernet card

• PROFIBUS connection with Woodhead’s card and server

Due to reasons explained in the next chapter, all main tests were performed with

Kepware’s LinkMaster OPC bridging software.

4.2 Basic Idea

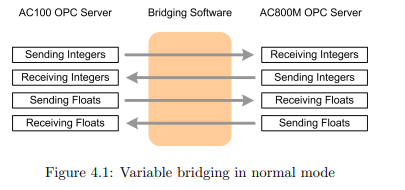

The basic idea behind all tests is the definition of a complementary set of receiving

and sending variables to each of the two controllers. During each controller program

cycle all receiving variables are read from the bus/network and all sending variables

are written. On the other side of the bus/network, the OPC server makes the

variables available. The OPC bridging software, acting as an OPC client to the

servers, links the two corresponding variables by reading the values from one server

and writing them to the other.

4.2.1 Short Circuit

To explore the behavior of one side or to isolate problems, we also performed test

with a “short circuit” configuration. That is, the bridging software is not configured

to link the variables from one OPC server to the other, but right back to other

variables on the same server.

4.3 Variables

This section informs about the type and quantity of variables used to test the

connection.

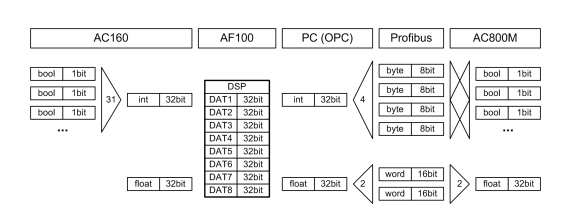

4.3.1 Data Types

According to the requirements, only 32-bit floating point and boolean values have

to be processed. Since the booleans are packed into integer values, the problem

modifies to the transport of 32-bit floating point and 32-bit integer values.

4.3.2 Packaging of Booleans

The are various reasons to pack booleans into integer values instead of processing

them one by one:

Figure 4.3: Data types in different sections with PROFIBUS

• The smallest possible PROFIBUS module size provided by both cards is one

byte. If processing booleans one by one, 7 bit would get “lost” for every value,

which reduces performance.

• In MMS telegrams, one single boolean requires 3 bytes space whereas one

integer containing up to 32 booleans uses only 6 bytes [17].

• A smaller number of variables improves the performance of the OPC connections.

• One can save a lot of configuration effort for the bridging software.

• AC800M supports transparent packaging of the booleans into PROFIBUS

modules, that is, it is not even necessary to manually pack them into integers.

• AC160 offers a program code element to pack/unpack booleans into/from

integers.

Since the size of one variable in an AF100 DSP is limited to 32 bit, we intended to

pack this amount of booleans into an integer value. However, the packaging program

code element offered in AC160 treats the last bit as a sign flag not compatible to the

transparent mapping of the AC800M. Instead of implementing additional program

code we therefore decided to set this last bit aside and pack only 31 bits into one

integer value.

4.3.3 Quantity

In order to learn more about the behavior of the concerned parts, we performed six

main tests with different amounts of variables:

• The first four Tests 0 to 3 are intended to get an overview on the behavior

of the configurations. They are designed such that they can run with all test

system variations, that is, the amount of data does not exceed 488 bytes in