ABBIndustrial Networks Connecting Controllers via OPC

Abstract

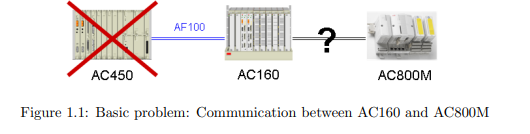

In order to modernize their infrastructure and keep up with the state of the art,

ABB Power Systems decided to replace the older controller AC450 with a new

generation of controllers called AC800M. Just like its predecessor, its main task is to

work as a sequencer in an otherwise mostly unchanging topology. Although the new

controller AC800M provides modern communication features and a sophisticated

application development system, it lacks of a communication interface compatible

with the residing controllers AC160. A hardware approach addressing this problem

is in development, but not available at this point of time. Thus the decision was

made to realize the connection using OPC, a widely spread and open software

communication interface standard with a high potential of reusability. In addition,

it was aimed at gaining additional knowledge about the OPC interface, which is

commonly used in industry.

In this thesis, we evaluate adequate hardware and software to realize this connection and we have programmed the controllers with applications to evaluate its

performance and integrity. In addition, we are making considerations about redundancy that is vital in automation business in order to increase reliability and

availability. We have shown that it is possible to interconnect controllers using

OPC with satisfactory average performance results. Due to high maximum round

trip times and high complexity when realizing redundancy, it is recommended to

use such a system for testing purposes or non-critical operational applications, but

not for critical systems. In this thesis we also identify and judge several alternative

ways of connection.

Acknowledgements

First of all, I would like to thank Prof. Dr. Bernhard Plattner of the Computer

Engineering and Networks Laboratory TIK at the Swiss Federal Institute of Technology ETH Zurich for supporting and supervising this Master’s Thesis. Special

thanks go to my advisors Rainer Baumann and Bernhard Tellenbach of TIK for

their straightforward and helpful support during my work.

Secondly I would like to thank Dr. Esther Gelle and Pascal Aebli of ABB for

enabling this Master’s Thesis in the first place as well as providing aid throughout

this thesis. Special thanks also to Stephan Egli for supporting me with the first

steps, Swen Woldau for numerous hints concerning AC160 and AF100 as well as

Juerg Beck for AC800M tips and tricks. Finally I would like to thank everyone else

at PSPD for the provided aid and making my work so convenient not only in a

technical but also in a human manner.

Baden, June 2007

Martin Pfister

Chapter 1

Introduction

This chapter will provide a rough overview of the problem treated by this Master’s

Thesis. All technical devices and expressions will be explained more precisely in

the next chapter. Please note that since this is a public thesis, it does not contain

sensitive company-internal data.

1.1 ABB Power Systems

ABB Power Systems is one of the world’s leading providers of infrastructure for

controlling combined cycle power stations and waste-to-energy plants. Such a

plant control infrastructure includes several hardware parts consisting of controllers,

input/output-boards and communication devices as well as many software components to engineer, run, observe and analyze the power plant. A power plant control

system has to satisfy a broad variety of different needs, from the efficient and reliable control of the turbines and associated supporting functions (such as lube oil)

to easy configuration and operation as well as to sophisticated analysis functions

addressing technical and economical aspects.

1.2 Problem Statement

Due to high investment costs, the technical management of power plants is a slowgoing business with long life-cycles. Thus, a considerable amount of hardware

devices currently in use are tens of years old. For future applications within ABB

Power Systems it will be necessary to connect a controller of the newest series used

within ABB, Control IT AC800M, with an older controller of the type Advant

Controller 160 (AC160). The problem is that these two controllers do not share

a fast communication interface of similar type and therefore cannot communicate

directly. The standard communication intended for AC160 is Advant Fieldbus 100

(AF100). However, AC800M can support a whole range of buses except for AF100.

As a consequence, the communication must be implemented using some relaying

technique.

1.2.1 The Use of OPC

It was decided in advance to realize the relaying connection using OPC. This solution was chosen because OPC is an open standard and very common in process and

automation industry. Furthermore, this solution offers a high potential to be used

for similar problems, since a lot of devices support this specification. However, OPC

is normally not used for fast controller-to-controller communication but for slower

visualization and logging purposes and there is no performance data available for

this kind of connection. The use of OPC is therefore both challenging as well as

interesting to gain more insights and know-how.

It is also to mention that a hardware solution addressing our problem is not

available yet. It is therefore necessary to have an alternative way using already