ABBIndustrial Networks Connecting Controllers via OPC

into the personal computer. The according AC100 OPC Server, which allows us to

access the AF100 bus, was installed with the 800xA for AC100 software extension

[19]. It is to mention that AC100 OPC Server allows access on bit-level, for example,

an integer value is presented by the server both as integer value and split up in 32

boolean values.

2.5.3 MMS Communication

An Intel Ethernet PCI card allowed the communication with the AC800M via MMS

on TCP/IP. The according AC800M OPC Server is part of the 800xA installation.

All communication over this port is performed via the Manufacturing Message

Specification (MMS) protocol running over TCP/IP, utilized for example by the

engineering tool to program the controller. The same connection can also be used

for controller to controller communication when having several MSS-ready devices.

Furthermore, the AC800M OPC Server communicates with the controller via the

same protocol and infrastructure, making available all variables by default [17].

2.5.4 Beckhoff PROFIBUS Communication

For the first PROFIBUS connection we used the FC3102 PCI card from Beckhoff.

This card was chosen due to its flexibility: It provides two ports in one PCI card

which can be freely adjusted either as master, slave or passive bus monitor [20].

We ran Beckhoff’s TwinCat software: TwinCat System Manager to configure

the card, TwinCat IO as driver and TwinCat OPC Server. Beckhoff inserts an

abstraction layer on top of TwinCat IO which operates with the ADS (Automation

Device Specification) protocol [21].

2.5.5 Woodhead PROFIBUS Communication

The Woodhead Electronics SST-PBMS-PCI card is the only card to be found that

provides multi-slave functionality. That is, even though the card only has one physical SUB-D9 interface, it can emulate up to 125 PROFIBUS slave interfaces [22].

This allows not only the simulation of large PROFIBUS outlines in one PC, but—

and more important to us—also makes it easy to bypass the 244 byte limitation

specified by PROFIBUS DP

Figure 2.13: Woodhead Electronic SST-PBMS-PCI card

We configured the card with its configuration tool SST Profibus Configuration.

Furthermore we used the according OPC Server for PBMS Card which was configured with Multi Slave OPC Configuration Utility

2.5.6 OPC Bridging Software

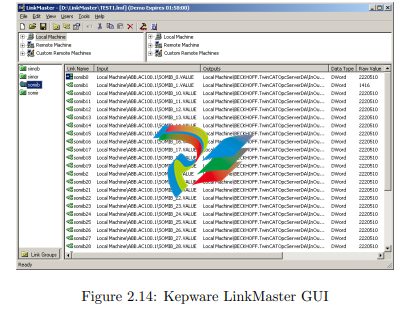

The programs we used to interconnect two OPC servers were Matrikon’s OPC

Data Manager (ODM) [23] and Kepware’s LinkMaster [24]. These programs called

OPC routers or OPC bridges are able to read data from one server and write

it to another. Both programs are similar in configuration and operation. The

functionality includes the definition of groups and update rates, input/output pairs,

dead-bands and quality checks. LinkMaster even allows to write one input value to

more than one output variables and to perform mathematical operations in between.

To make bulk configuration easier (e.g. with Excel), both programs allow to import

and export the configuration from and to comma separated values (CSV) files.

Figure 2.14: Kepware LinkMaster GUI

We ran both bridging programs with a fully functional, time-limited testing

license provided for free by its vendors for the duration of our thesis.

2.5.7 Helper Programs

For setup and testing, a range of other software was used on the engineering/test

system computer. The most important programs are shortly specified here:

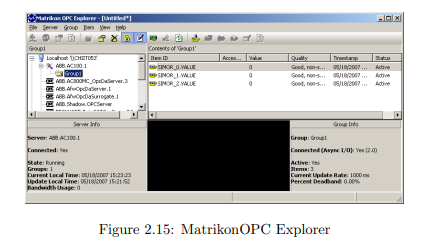

• MatrikonOPC Explorer is a freeware OPC client allowing to connect to

any compliant OPC server and displaying the value of chosen tags. It also

supports writing of variables and preserving settings. Furthermore, it allows

measuring the maximum update rate of the OPC servers it is connected to.

• Office 2003 of Microsoft was used for day to day work and configuration

tasks. Especially Excel was helpful for variable definition in AC800M and for

bulk configuring the bridging software using CSV files. Furthermore, with the

Bulk Data Manager plugin, Excel allows convenient bulk setup of PROFIBUS

devices and its variables.

• Process Explorer of Microsoft’s Sysinternals is a freeware program to monitor system processes and their use of resources.

• Synergy was used to operate two computers and screens with only one keyboard and mouse.

• Irfanview helped with the caption of screenshots.

Chapter 3

Test System

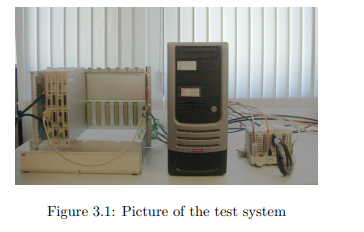

This chapter describes the test system we used for our evaluations.

3.1 Overview

The main goal is to connect a controller of the type AC160 with a controller of

the type AC800M which do not share a common communication interface. As

this happens using OPC, the intermediate relay is implemented using a Windows

computer. While there is only one possibility to connect AC160, we tried out

different approaches for linking AC800M.

3.2 AC160 Side

The AC160 is attached to the personal computer via the CI631 using the Advant

Fieldbus 100 and a PCI card CI527. Due to limited communication facilities, this

is the only reasonable choice for this task. Since both communication interfaces

inherently support line redundancy (see Chapter 6), two media were used for this

connection. To program the processor module either a separate EIA-232 connection

or the AF100 fieldbus itself was used. The according AC100 OPC Server is part of