ABBIndustrial Networks Connecting Controllers via OPC

provided they are situated in different communication interfaces. That is, multiple

interfaces can receive the same CDP. The cycle time determines how often the data

of the CDP is transferred on the bus. When a CDP is transferred on the Advant

Fieldbus 100, the interval between consecutive transfers is always the same, the

cycle time. Thus, process data transfer is deterministic, regardless of which other

tasks the communication interfaces perform.

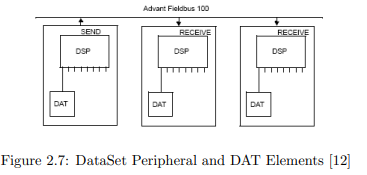

Figure 2.7: DataSet Peripheral and DAT Elements [12]

In AC160, one so-called DataSet Peripheral (DSP) can reference up to eight

32-bit values called Database Elements (DATs). Each DSP uses one CDP to be

transported on the AF100, and can therefore be configured for example with an

individual cycle time. In addition to cyclic message transfer, AF100 offers the

possibilities to send event-based messages using the Service Data Protocol (SDP).

This does not influence the cyclic data transfer at all. At a bus length up to 2000m

it is therefore necessary to keep the cyclic bus load under 70% in order to have

extra space for messages (depicted as gray fields in Figure 2.6) [12].

2.4.2 PROFIBUS DPV0

PROFIBUS (PROcess FIeld BUS) is one of the world’s most widely used fieldbuses and was launched in 1989 by a consortium of companies and institutions.

Until today it was continuously enhanced and extended [13]. It is available in three

variations:

• PROFIBUS-FMS (Field Message Specification) was the first PROFIBUS

communications protocol. It offers sophisticated functionality but is no longer

officially supported.

• PROFIBUS-DP (Decentralized Peripherals) has been designed for fast cyclic

data exchange at field level and is today often referred to DPV0. This specification was extended with DPV1 for acyclic and alarm communication and

DPV2 for slave-to-slave and isochronous communication as well as synchronized system time.

• PROFIBUS-PA (Process Automation) is used for the connection of devices

to a superior process control system. It supports intrinsic safe transmission

[14].

For this thesis, only the DPV0 protocol specification is relevant. Therefore,

when writing PROFIBUS, we are always referring to this specification. DPV0

allows the cyclic exchange of data from a master (initiator) to slaves and vice versa

at a high data rate up to 12 Mbit/s. Communication is organized in input and

output modules of defined size (e.g. one word or four bytes) for every slave, which

then are transmitted completely (non differential) once per cycle. The cycle time

depends on the number of bytes and slaves as well as on timeout settings. The

specified input and output data of one slave is limited to 244 byte each. While the

physical connection can also be established using fiber optics, we used the more

conventional EIA-485 electrical twisted pair connection.

PROFIBUS slaves come with a GSD-File (“Geraete-Stammdaten” in German)

which is an electronic device specification. Most PROFIBUS master systems allow

to directly import the GSD-Files of previously unknown slaves in order to include

them in the bus planning. That makes it easy and comfortable to build PROFIBUS

networks with slaves from different vendors.

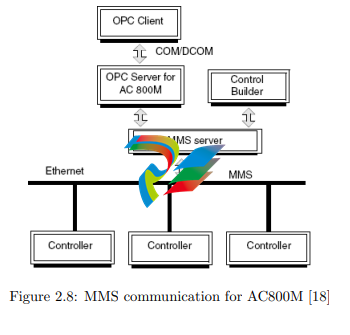

2.4.3 MMS

The Manufacturing Message Specification MMS is an application level protocol developed during the eighties by General Motors. Its main goal was to unify communication to controllers independent of manufacturers. Other automobile, aerospace

and PLC companies adopted the protocol and since 1990 MMS is standardized in

ISO/IEC 9506 [15]. While being very general and open, MMS is reputed as heavy,

complicated and costly. Nevertheless MMS was an important step in development

and due to its independence of the underlying communication protocol it is still

being used today. Furthermore it worked as a reference model and has influenced

other protocols. Since 2002 the standard IEC 61850 for “Communication networks

and systems in substations” based on TCP/IP over Ethernet defines the mapping

onto MMS [16].

MMS is used as the main communication protocol for AC800M. On one hand,

this is the communication between controller and the superior control and engineering system, on the other hand the communication between several controllers

of this type as shown in Figure 2.8. One telegram can reach a size up to 1024 bytes

including the header, containing a maximum of 159 integers or 136 floats [17]

2.5 Personal Computer

For our tests we used a personal computer containing an Intel Pentium 4 processor

at a speed of 3.2 GHz and 2 GB memory running a Microsoft Windows Server 2003

R2 operating system

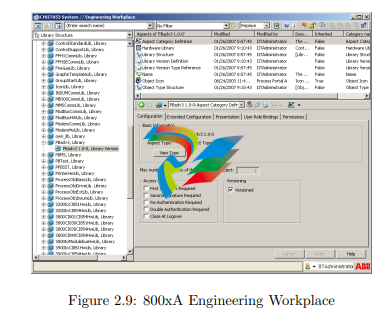

2.5.1 800xA and Development Environment

In order to setup, program and run ABB components, an Industrial IT 800xA

environment was installed on the personal computer. Besides a lot of additional

resources, this installation also encompasses the application development systems

for both controller types.

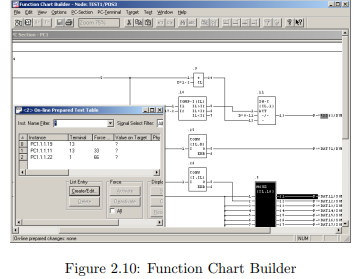

The development environment to program the AC160 was Control Builder A

(CBA) consisting of Application Builder, Function Chart Builder and Bus Configuration Builder. To program the AC800M controller, the engineering tool Control

Builder M was used.

2.5.2 AF100 Communication

To establish connection to the AF100 fieldbus, we inserted an ABB CI527 PCI card