ABBIndustrial Networks Connecting Controllers via OPC

OPC Unified Architecture (OPC UA) and is independent of COM, thus being able

to run on more operating systems as well as embedded devices [5].

2.2.1 OPC Data Access

OPC DA is organized in the hierarchical structure server, group and item. Items

correspond to variables and can be read and written. Furthermore, a quality and

time stamp is provided with each of them. When reading items, the value usually

comes from the OPC server’s cache, which is updated periodically with the values

of the device (or bus, component). However, it is usually possible to force a read

directly from the device. Clients organize their items in groups, which for example

share the same access method and update rate. Each OPC server has an unique

name, some vendors even offer the operation of multiple servers for the same device.

OPC DA provides different methods to access items, first of all synchronous and

asynchronous read and write operations. More important to us, there is also a

subscription mechanism, which is commonly used by modern clients in order to

reduce communication. That is, the client group subscribes to the server which

then “pushes” values towards the client only if they changed respectively exceed a

pre-defined dead-band. The client can force an update of all these values by issuing

a refresh call, which corresponds to an asynchronous read for all items of a group

[6].

2.3 Programmable Logic Controllers

This section informs about the two controllers involved and about the controller

that has to be replaced. Please notice that we use the term controller equivalent

to programmable logic controller (PLC) throughout our Master’s Thesis.

2.3.1 Advant Controller 160 (AC160)

The AC160 series was launched in 1997 to meet high speed requirements in turbine

control. To this day its outstanding performance is needed for fast closed loop

control (CLC). For our work, we were provided with a rack RF616 for the physical

mounting of the controller parts. The rack also delivers power to each device

and includes the BIOB Backplane Input/Output Bus which, among other tasks,

processes the communication between the processor module and the communication

interface. The tests in this Master’s Thesis were done with processor modules

of the type PM665 (containing a Motorola MPC8240 processor) and the AF100

communication interface CI631, both supporting redundancy [7]. To program the

processor module, its built-in EIA-232 interface was connected to the engineering

PC.

2.3.2 Advant Controller 450 (AC450)

AC450 is the controller to be replaced by the new generation. Its processor module

is built up around a Motorola 68040 microprocessor running at 25 MHz [8]. While its

performance is quite limited, AC450 also lacks of modern communication interfaces

and standards like Ethernet, which become more and more important.

2.3.3 Control IT AC800M

Control IT AC800M is the most current controller series used within all of ABB,

introduced in 2001 [9]. It strikes with its small outline and offers modern communication interfaces. For our tests we were provided with a processor module

PM864A which contains a Motorola MPC862 microprocessor running at 96 MHz

[10]. In addition to two EIA-232 interfaces, the processor module of AC800M offers

two built-in 10 Mbit/s standard Ethernet ports, used for instance to connect to the

engineering computer.

The communication interface CI854A is a sophisticated device to establish

PROFIBUS communication. The device even offers an own web interface which

allows e.g. the surveillance of the cycle time. The device is directly coupled to

the processor module via the Communication Extension Bus (CEX) [11]. At this

point of time, CI854A can only act as a PROFIBUS master, but not as slave. As

a consequence, communication partners must be slaves.

2.4 Bus and Network Communication

This section describes the different communication approaches used in our system.

2.4.1 Advant Fieldbus 100 (AF100)

AF100 is a high performance fieldbus system with time synchronization and the

most popular fieldbus used within ABB, common to almost all platforms. Although

the name Advant Fieldbus 100 is ABB proprietary, it complies to IEC standard

61375-3 as well as US-standard IEEE 1473 and is widely used in railways under

the name of MVB. AF100 works over twisted pair, coaxial and optical media at

a rate of 1.5 Mbit/s. For our system we made use of the first method only. Bus

master responsibility is shared by all communication interfaces with administrator

capabilities, that is, a bus master controls all communication for a certain time

interval and then passes on the bus master token. However, in our setup only AC160

were given administrator capabilities, even though the PCI-card would support

them as well.

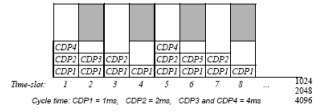

Figure 2.6: AF100 time-slot organization up to 2000 m bus length [12]

AF100 is a planned bus with a pre-determined scan table and thus meets realtime requirements. Process Data Transfer is managed through Cyclic Data Packets

(CDPs). Each CDP is configured individually on the communication interface for

a certain signal identity, cycle time, size and direction. Each broadcasted CDP has

a unique signal identity, whereas receiving CDPs can have the same signal identity,