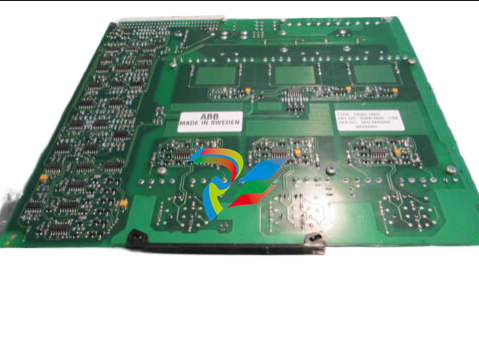

ABB Process Gas Chromatographs PGC5000A Generation 2 Master Controller

Process Gas Chromatographs PGC5000A Generation 2 Master Controller

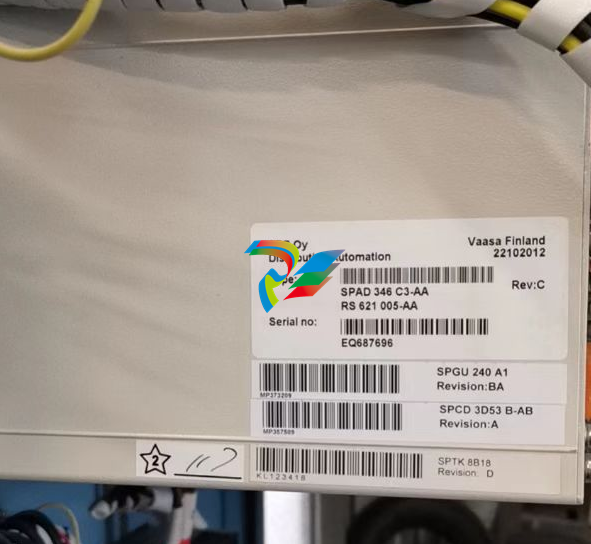

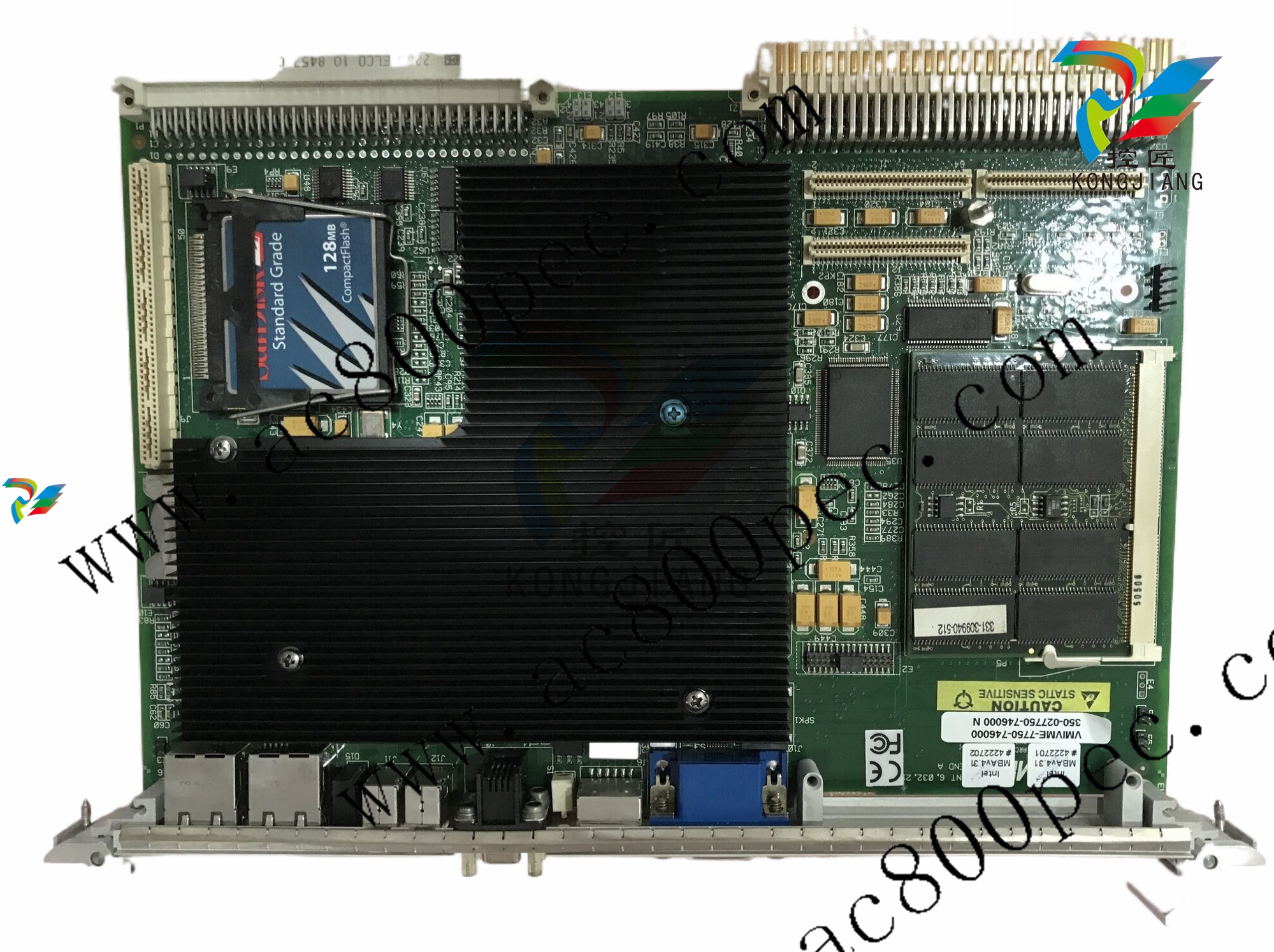

The PGC5000A Generation 2 Master Controller provides all of the analyzer system control functions and coordinates internal and external data activities for the PGC5000B, PGC5000C, PGC5007 and PGC5009 Smart Ovens™. Analyzer and the control systems communicate via intrinsically safe (IS) Fiber Optic with Redundant Ethernet, Modbus or Modbus RTU.

Features of PGC5000A

10” SVGA touch screen with multi-touch control supports the HMI

Simple tab layout for ease-of-use

Universal touchscreen

Intrinsically safe fiber optic connections to multiple Smart Ovens

Redundant Ethernet ports for guaranteed data transfers

Standard USB ports for convenient system updates

Direct MODBUS communication

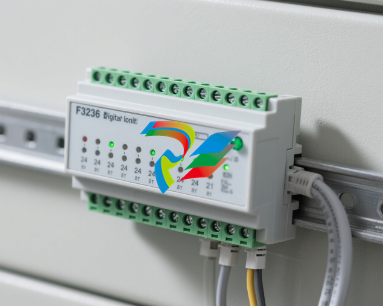

Comprehensive I/O options

Are you looking for support or purchase information?

Contact us

The PGC5000A Generation 2 Master Controller with new Graphical Driven HMI offers a fully functional touchscreen. Developing, editing and storing analysis methods are now easy.

Programming is now a thing of the past. Just “point and click” is all that is required to access any of the analyzer functions. All of the major analyzer functions are identified on tabs making it easy to know where to go to access information when needed.

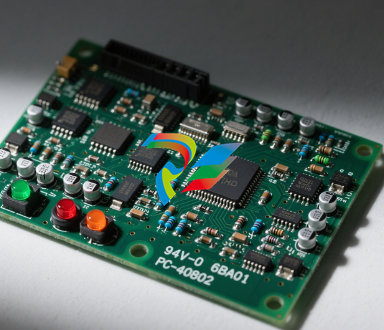

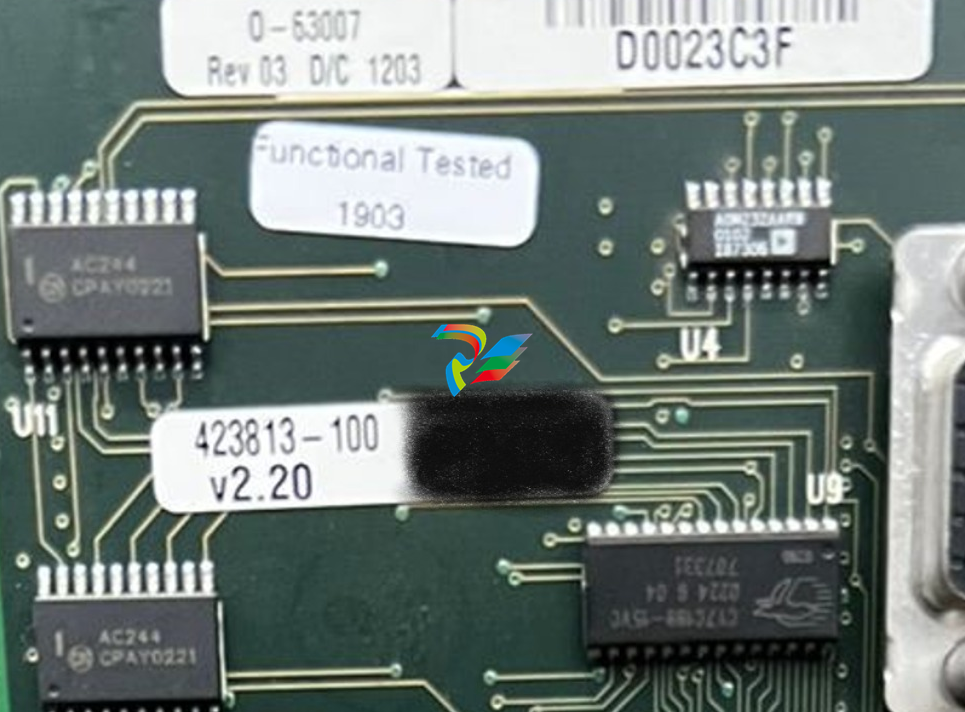

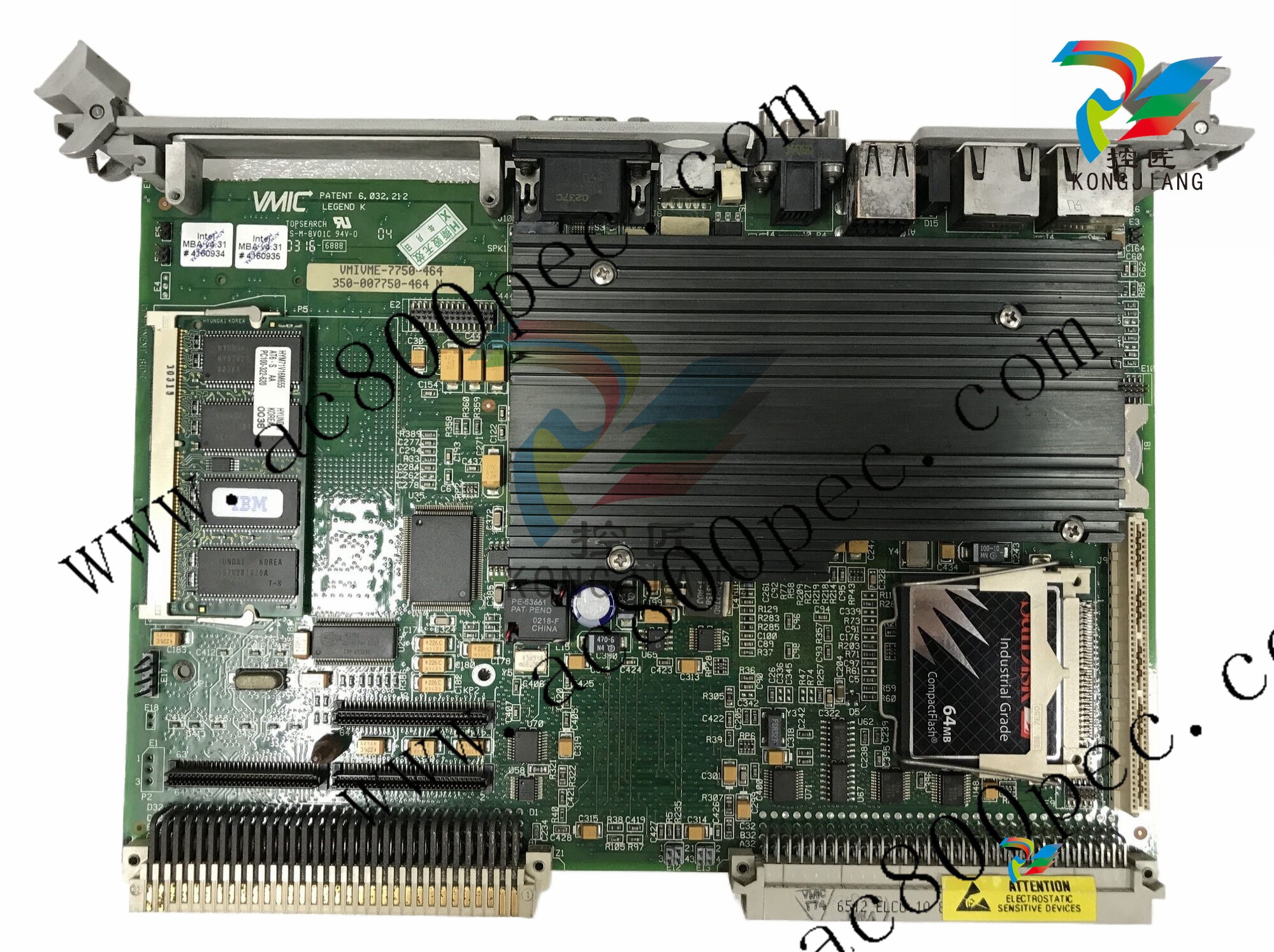

PGC5000 Integrated controller

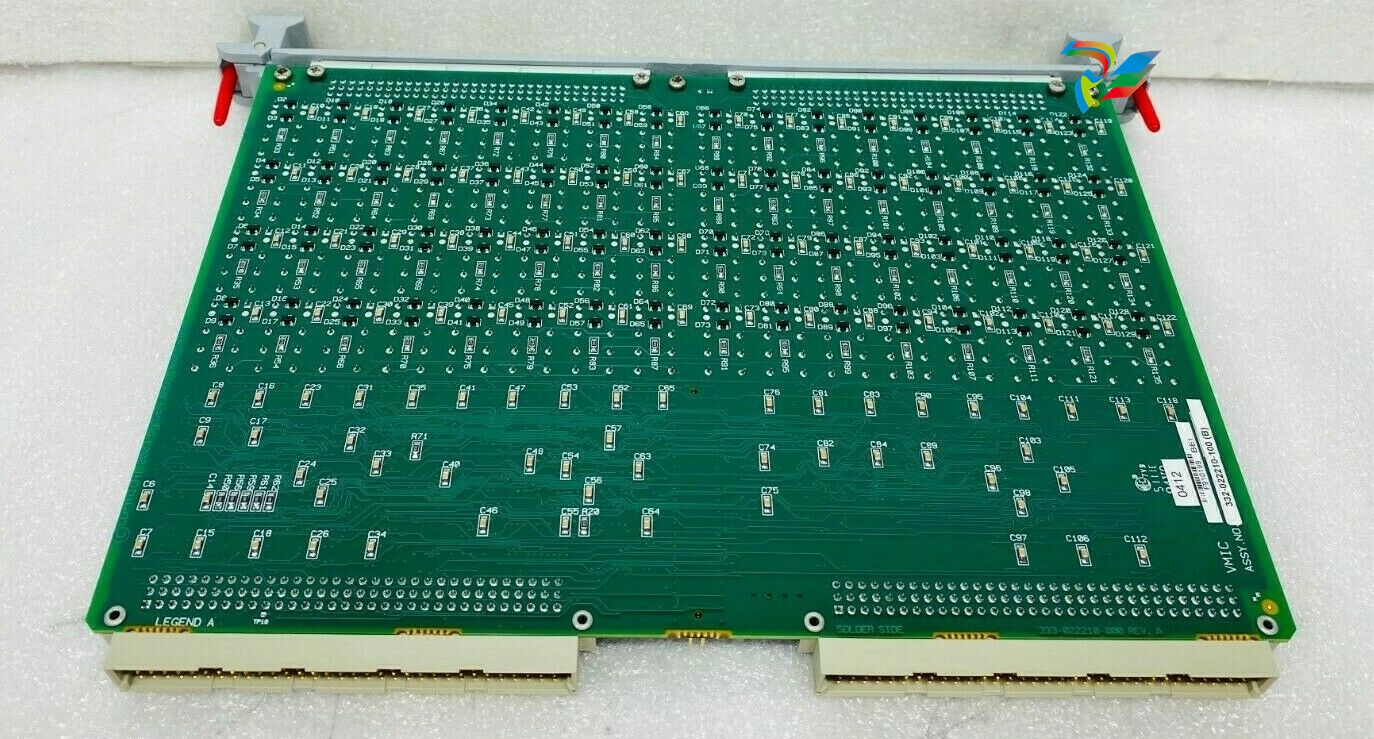

The PGC5000 Integrated Controller combines the core functionality of the PGC5000A Master Controller into either the PGC5000B or PGC5000C Smart Oven.

Features:

The end users can use the existing network available in the shelters to communicate with the process gas chromatographs, using either a standard PC, industrial tablet or Master Controller.

Wireless communication by adding a wireless access point device, i.e: MOXA device

Benefits:

Cost savings (SIUs, EPCs and End Users)

- Reduces shelter footprint

- Reduces HVAC capacity

- Optimizes oven installation

Reduce analyzer costs