EMERSONDeltaVTM Digital Automation System

To develop and maintain a competitive advantage, it’s time to take your plant digital, with the first fully digital automation system—the DeltaV™ system. With a suite of digital busses, precision advanced control, and easy enterprise integration and optimization, the DeltaV system helps you improve your operations—easy

The DeltaV Digital Automation System

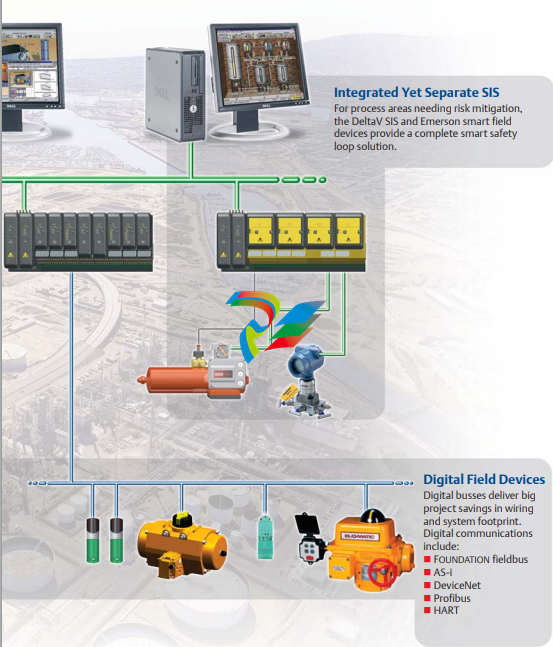

igital plants made easy PlantWeb® is a digital plant architecture that delivers proven results, and the DeltaV system makes it easy. Designed with this digital architecture in mind, the DeltaV system fully integrates “smart plant” capabilities including HART®, FOUNDATION™ fieldbus, high-speed discrete busses, embedded advanced control, and advanced unit and batch management. This seamless, intelligent field integration provides the infrastructure for advanced applications such as AMS Suite: Intelligent Device Manager for quick, easy device re-ranging, configuration and diagnostics. The results are better process efficiency and reduced process variability. Any size you want The DeltaV system scales in both size and functionality. It’s the first fully digital system to offer you a single architecture with full functionality from a few to hundreds of thousands of I/O, so you can cost-effectively implement applications of any scope. You pick the functions that work best for your application across the entire system size. The DeltaV system integrates easily with your existing automation systems to provide you a path forward, allowing you to benefit from the latest costsaving technologies. Leading the way The DeltaV system has delivered a host of industry firsts—including simple plug-and-play OPC and XML integration, FOUNDATION fieldbus, batch control, and advanced control technologies. Being first with these technology innovations has made our users pacesetters in their industries. But more important, it’s delivered dramatic operational improvements: the kind of improvements you can start profiting from today. Results that deliver It’s no wonder that process automation professionals like you have voted the DeltaV system the leading process automation system for four consecutive years.† In the following pages, see why

A Better Approach to Digital

The DeltaV system, a key component of the PlantWeb architecture, is the world’s first digital automation system

Built with today’s technologies like PC workstations, Ethernet, digital busses, OPC and XML, the DeltaV system delivers more precise control, and predictive maintenance. And it delivers that information where and when it’s required. Unlike other systems, the technologies were built from the ground up into a digital automation architecture, not bolted on after the fact. That’s what makes the DeltaV system easy to learn, easy to use, easy to maintain, and easy to connect to your existing automation.

Availability While the DeltaV system is built with quality components, many customers seek further assurance—like the demands of increased uptime. You can choose the level of redundancy your application requires, including: Redundant Ethernet network communications Redundant controllers Redundant power supplies Redundant H1 FOUNDATION fieldbus interface and bus power

Redundant digital HART I/O Redundant MODBUS and other RS485 serial communicatio

Rugged control and field interfaces Built to mount anywhere— minimizing your installation costs and ensuring safety. Meets: Class 1, Div. 2 Zone 1 and 2 Intrinisically safe options G3 corrosion resistance -40 to 70°C.

Commercial off-the-shelf technologies Proven, low-cost, easily integratable commercial technologies are the fundamental building blocks of the DeltaV system: technologies proven across many industries and known by a wide pool of professionals. Windows workstation and server-based PCs Ethernet technology Bus standards.

Automation–Easy

“The unique design of the DeltaV digital automation system simplifies the installation and commissioning process, enabling us to complete the project five months ahead of schedule ....The quality of the gas is better than the standard of the Grade A specification.” — Mr. Liu Yi Changquing Oil Field Company

You are faced with many options for automating your plants. What separates the DeltaV digital automation system?

Key system services built into the DeltaV software include: Peer-to-peer communications History services Event services Alarm services Time handling Hot expansion services Tag look-up services Diagnostic services On-line upgrades.

Peer-to-peer awareness The DeltaV system keeps a realtime database available to all connected PCs and controllers. Functions difficult or impossible to implement in component-based solutions easily done in the DeltaV system include: System-wide alarm management Global security by user and function System and device diagnostics.

Precision time keeping Across all PC workstations and controllers, precise time can be synchronized to the atomic clock. Time synchronization is available with full redundancy. Precision time means: Accurate, system-wide history Faster root cause analysis Sequence of events is built-in, not a 3rd-party add-on.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)