Industrial DevOps Is Redefining PLC Engineering Process

“Users can open browser-based functionality directly from the version in the repository,” explained Kilfoy. “Users can open it and can edit that code. The entire [Software Defined Automation] product is 100 percent cloud based, except for a gateway.”

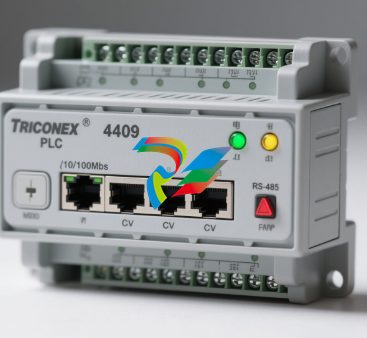

Secure remote access

According to Kilfoy, Software Defined Automation’s cloud-based secure remote access control is 11 times more secure than self-managed VPNs such as Cisco and Citrix, which helps protect against ransomware. It controls who accesses each product and device/PLC. The on-demand connection uses encrypted MQTT and WireGuard VPN for secure OT device access. Secure remote access records every action for full transparency and auditability.

“Our secure gateway is software that runs on an IPC,” explained Kilfoy. “We install it, we configure it and at that point you can start adding PLCs to it. That gateway also gives us the ability to do a full secure remote access solution.”

Virtual PLC management

“Virtual PLC orchestration or management is the same idea as CODESYS,” said Kilfoy. “We can deploy CODESYS the same way that we deploy Rockwell or Siemens. We also manage the DM [device mapper] or the docker. Our virtual PLC, or soft PLC, orchestration goes into version control just like everything else. AI is built into it. Everything is fully integrated.”

Virtual PLC management allows users to gain independence from vendor-specific hardware. It allows users to run soft PLCs with real-time performance on standard IT servers with edge virtualization. It deploys quickly, allowing users to launch virtual PLCs in seconds and manage them alongside conventional PLCs in a single platform. Its unified workloads combine real-time and non-real-time tasks on the same hardware. In addition, because of integrated operations, users can run human-machine interfaces, monitoring and data analysis on the same factory hardware.

AI for automation

Software Defined Automation uses its Factory Agent AI to translate PLC code into human language, which enables engineers to grasp complete automation/PLC projects quickly and also get up to date process documentation. Because PLC code is streamlined into human language, new employees and/or consultants can be onboarded faster. Being able to “read code” in human language ensures always-current program documentation. “Factory Agent does a reverse translation to provide documentation,” said Kilfoy. “There’s nobody [else] out there that does this for PLC code that I’m aware of.”

Cybersecurity

Kilfoy said that there has been a 41 percent increase in ransomware attacks in manufacturing since 2020. The average cost of recovery from a ransomware attack in manufacturing is $1.67M and 22 percent of them take longer than a month to recover. “The biggest conversations that we get into most recently have been about cybersecurity and ransomware attacks,” he said.

According to Kilfoy, Software Defined Automation’s advantage is because they are not in the factory. “When a ransomware attack comes in, it attacks the PLC, but it also attacks everything else in the footprint. The blast radius includes things like the Rockwell Studio 5000, the TIA Portal and the machines they are on. It also includes things like the license server for those. In addition, 53 percent of the backups [when they were attacked] are encrypted, so the backups themselves are getting hit. With some of the solutions we compete against, the backup is off-prem, but the tools to do the backup and to recover the backup are on-prem, including the licenses.”

The company’s cloud-based approach helps protect against ransomware attacks by isolating the backup and recovery processes from the on-premises infrastructure. “From a security standpoint, we’re an AWS partner. We help our customers with support on their NIST Cybersecurity Framework 2.0 journey,” explained Kilfoy.

Looking ahead

Software Defined Automation envisions a future where PLC management and development is simple, secure and efficient, so that factories can increase uptime, reduce mean time to recover and maximize the productivity of their assets. Industrial DevOps can simplify these PLC management and development tasks, increase factory uptime and efficiency, as well as improve security in a single comprehensive, integrated solution.

Software Defined Automation’s solutions allow users to quickly back up and recover code, track PLC code changes across multiple vendors, enable remote and secure access control, streamline development and enhance collaboration, translate PLC code into human language and gain independence from vendor-specific hardware.

.png)