Managing SCADA During a Municipal Water/Wastewater Capital Project

Common SCADA and process design issues

Common SCADA and process design issues that are often encountered on municipal water/ wastewater infrastructure projects include:

Improperly sized flowmeters: Flowmeters should be sized based on the expected flow rate, not the pipe size leading to them. If a flowmeter that’s too large is installed, it can read unreliably or suffer from sludge/sediment buildup due to flow velocities being too low.

Poor locations for instrument taps: Welldesigned tap points for instruments are accessible and are clearly shown in the drawings. Good practices include having full port shutoff valves on each port for isolation, having spare ports and locating tap points so they won’t be prone to fouling/sediment.

Sample lines that are too long: Long sample lines, or sample lines that are poorly sized, can result in long dead times for the sample to pass from the sampling point to where the analyzer will see it.

Chemical dosing lines that are too long: Long chemical dosing lines create the same problem as long sample lines. Long dosing lines can make it difficult (or impossible) for chemical dosage adjustments to affect the process as desired.

Misplaced or missing air relief valves: Not having enough air relief valves installed in the high points of piping systems and on pump discharges can result in problems with trapped air in pipes, vapor locking and erratic flow behaviors.

Inappropriate use of valve types: Butterfly valves should not be used as control valves, as they do not effectively control flow and if used as control valves, they can rapidly deteriorate due to cavitation.

Improperly sized control valves: Improperly sized control valves will never work properly, no matter how sophisticated the software-based control scheme is. For example, control valves should be sized based on an appropriate valve coefficient (Cv) rather than just the line size.

Missing pressure testing instructions in contract documents: When no guidance is provided in the contract documents to the construction team, mistakes can easily happen. This can include rupturing instrumentation and diaphragm seals, incomplete testing or missing test documentation.

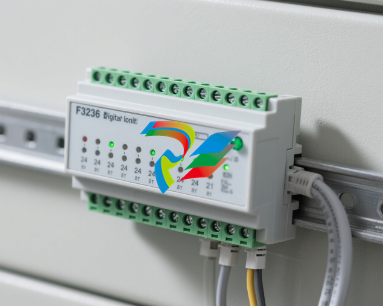

Missing SCADA and/or network details: Incomplete process control narratives, missing PLC hardware details or no clear instrumentation and controls (I&C) wiring guidelines are a recipe for delays and extra costs during construction.

These are only a sample of the many potential design issues that can happen when the detailed design of a municipal water/ wastewater facility is rushed by a design team. The important takeaway here is this: Use a team approach to ensure that enough QA/QC is done on the design package to catch potential problems at the design stage, when they are much cheaper to resolve, rather than during the construction stage. Often, when a problem is not fixed during design, it can cost 10 to 20 times more to resolve during construction.

Construction phase

Once the construction project has been awarded, a construction kick-off meeting will be held, followed by regular construction meetings between the utility, the design team and the construction team. The construction schedule will be reviewed and details relating to the construction will be coordinated as needed.

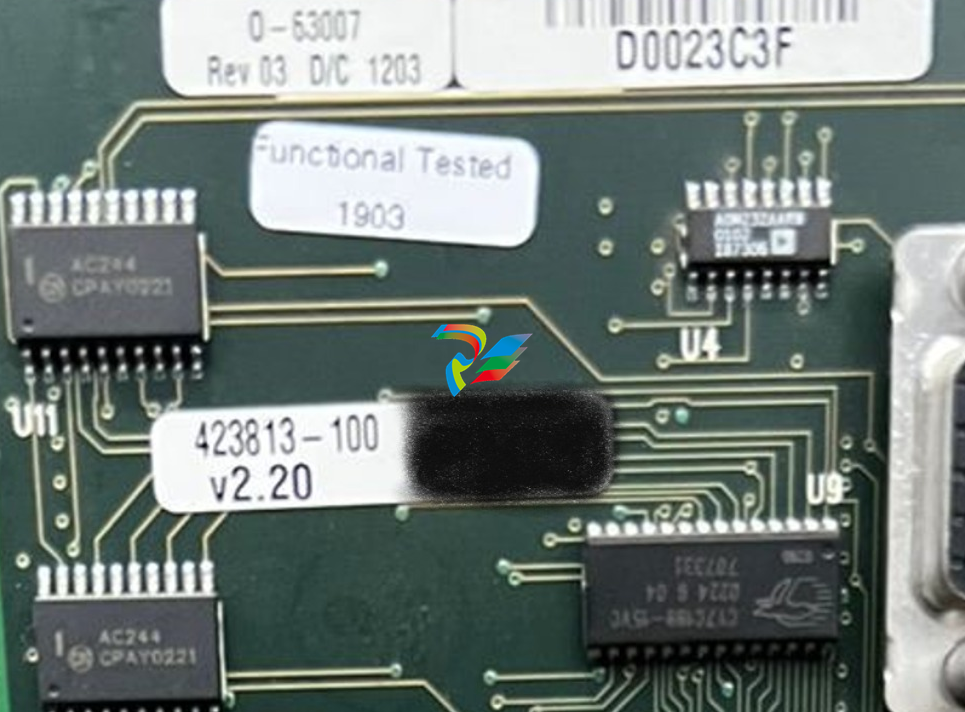

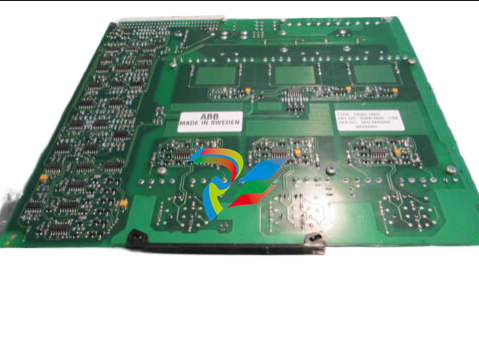

As part of the construction process, the contractor issues shop drawings that consist of specification sheets and other submissions for the various products the contractor proposes to install along with information about how they propose to install them. These will be reviewed by the design team and the utility as needed prior to installation.

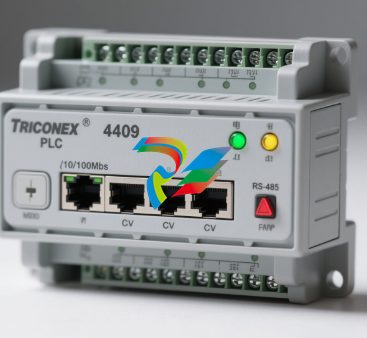

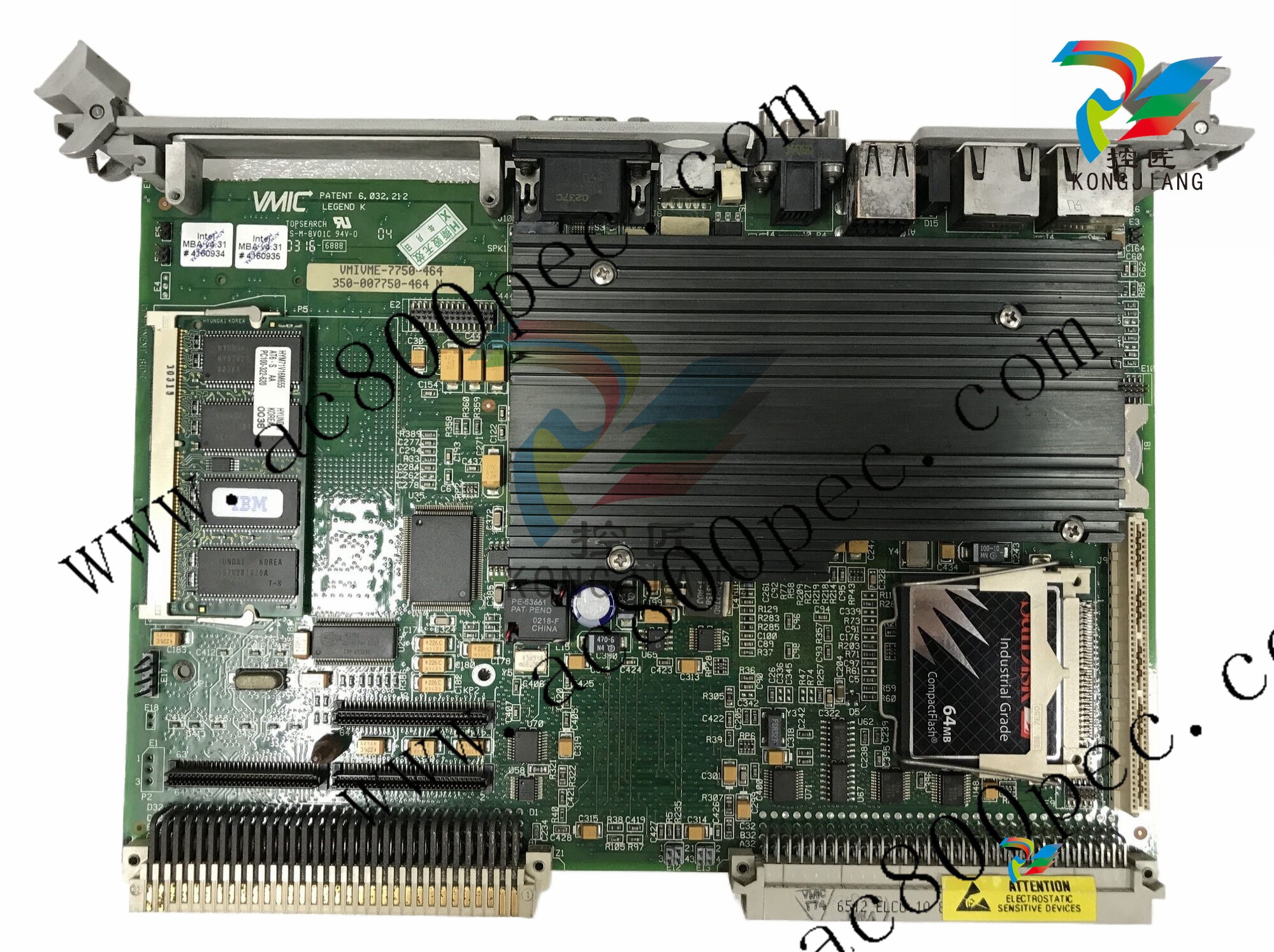

The shop drawings must be reviewed by the various design disciplines that are impacted by them including the utility’s SCADA team. Most SCADA professionals will want to review the shop drawings for automation equipment, instrumentation and any other equipment that “has wires” attached to it, to ensure the automation aspects of the project are properly coordinated.

SCADA construction aspects

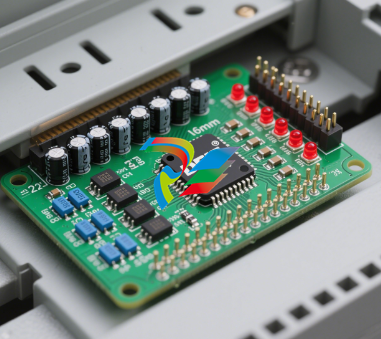

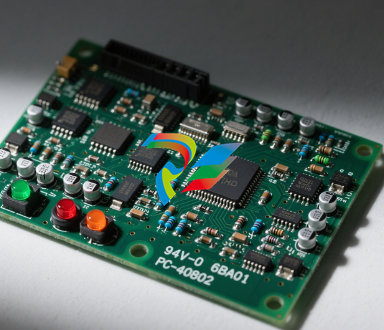

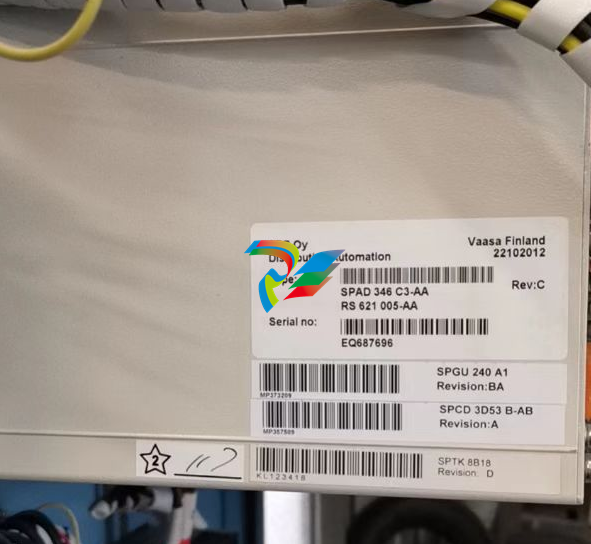

While the physical construction is taking place, a system integration team works on the offsite SCADA aspects of the project. This typically involves PLC panels, instrumentation and automation programming. Depending on how the project is structured, these three aspects may be handled by one team or may be split up among several teams that coordinate with each other.

A series of factory acceptance tests (FATs) will be held for the various pieces of automation/SCADA equipment and software. These are typically reviewed by the design team and the utility’s inhouse SCADA team prior to installation. Depending on the aspect, they will also be reviewed by the utility’s operations and maintenance team as well. As with any fabrication/development phase, it is best to resolve problems as early as possible to avoid costly rework later.

Commissioning

Commissioning is the step where the various pieces of installed equipment, software and support systems onsite must work together as a system for the first time. Best practice is for a detailed plan to be developed and followed for the commissioning stage as it will involve a lot of people to start up the various pieces of equipment and support systems. Most commissioning teams maintain a commissioning logbook and ensure that all tests are documented and signed off as the plant commissioning proceeds. Commissioning can be very time consuming so it is important that is it carefully planned out and coordinated.