Managing SCADA During a Municipal Water/Wastewater Capital Project

Commissioning usually starts by individually checking each piece of equipment before attempting to run it together. These individual checks usually start with visual inspections, configuration checks, test runs and testing various auto-shutdown conditions. Only after individual checks are complete can the entire system be tested together.

Also, equipment, systems and subsystems should always be tested in manual mode before attempting to run them under automatic control. Commissioning can be very time consuming because all the possible operating modes, and issues must be carefully checked, and adjustments made as needed, for all aspects of the facility.

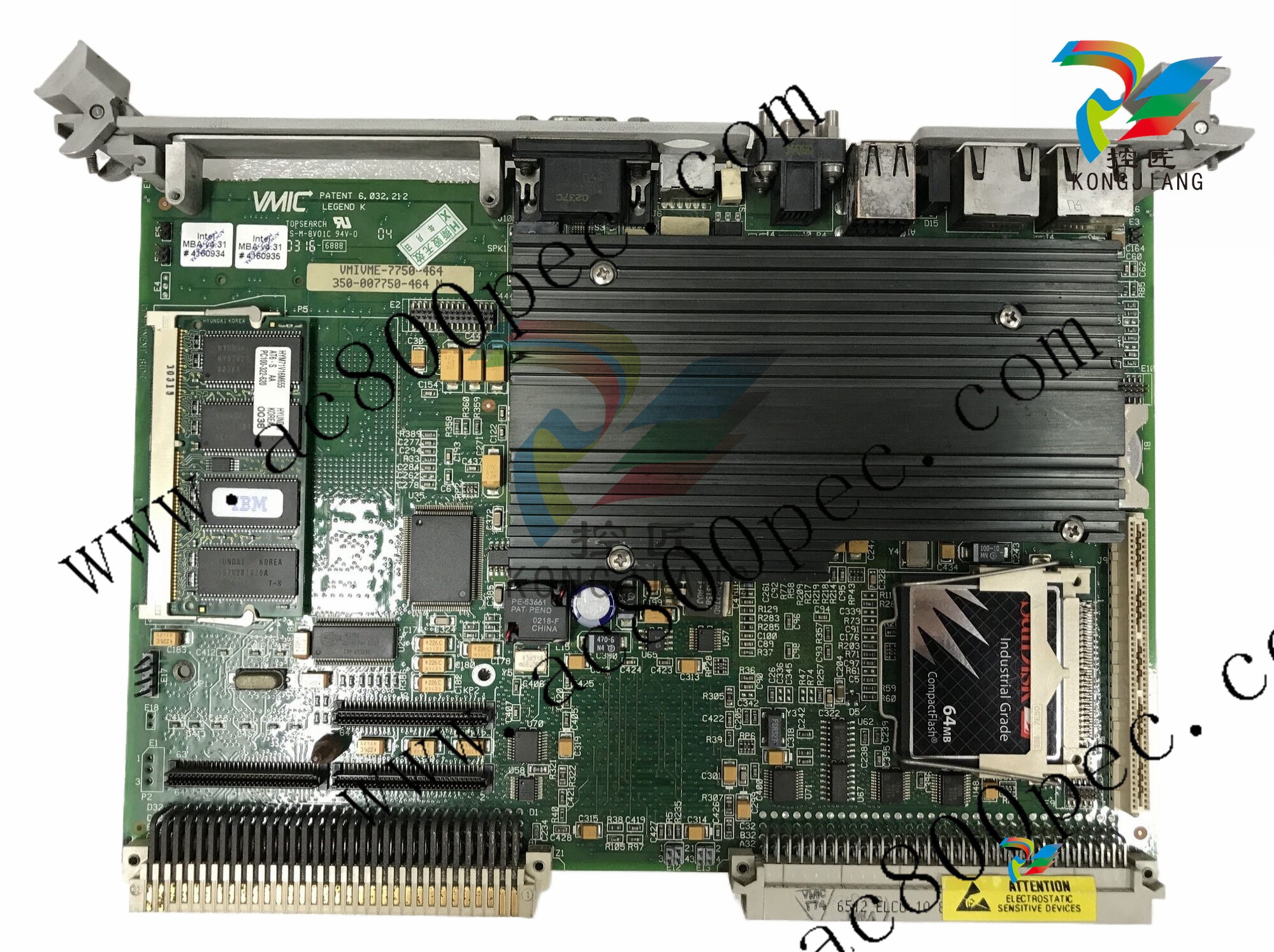

From a SCADA perspective, commissioning usually involves power-on checks, I/O wiring checks, loop checks and informal testing, followed by formalized site acceptance tests and site integration tests.

Performance test

After all the commissioning tests are complete, the facility enters a performance test period in which it is expected to run with few, if any, adjustments. It is not unusual to see a seven-, 14-, or even 21-day performance test run specified in the construction contract for a municipal water/wastewater facility.

Close-out

The successful completion of the performance test does not signal the end of the project. The design and construction teams must now document what has been built in a series of submittals into various project closure documents which will include operations and maintenance (O&M) manuals and as-built documentation.

A typical contractor-provided O&M manual will include the specifications and manuals for every component installed in the plant, along with copies of the associated approved shop drawings, and copies of the configuration settings and commissioning reports that were used for commissioning it.

The system integrator will provide an O&M and as-built package that consists of backups of any automation code and documentation on how the various automation systems work. Finally, as part of the ToR’s scope of work, the design team will provide an O&M submission for how the plant is intended to operate from an operations point of view, plus a full set of as-built drawings to reflect how the plant was built.

Final thoughts

Building critical infrastructure is a complex process with many moving parts. It is a team effort that requires personnel who have a wide variety of skillsets working together during all the various project phases for the result to be a successfully operating facility. Because of the prevalence of automation, automation professionals are an essential part of this team effort. By being involved at every step of the process, automation professionals continue to make the world a better place with automation when it comes to critical infrastructure.