How Industrial Ethernet Is Reshaping Industries

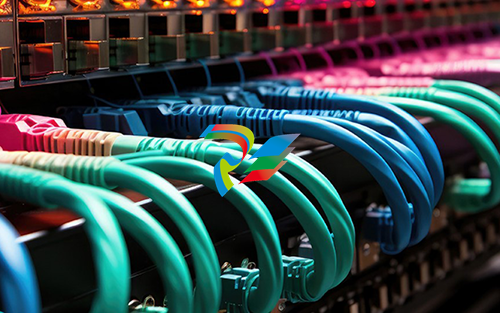

In the era of Industry 4.0, where machines communicate, automate and optimize processes, the need for robust and reliable networking solutions has never been more critical. Industrial Ethernet has emerged as the backbone of industrial connectivity, enabling seamless communications, enhancing efficiencies and paving the way for advances in various sectors.

Legacy connectivity methods such as serial, twisted pair, coaxial and other proprietary protocols and methods, are now giving way to standards-based Ethernet. This transition is being driven by several key factors such as the need for interoperability across diverse industrial devices, higher bandwidth for data-intensive communications, better integration with information technology (IT)-driven enterprise systems, lower costs incurred in using standard rather than proprietary products and more.

Today’s Ethernet can do much more than provide high-speed connectivity at lower costs. This article presents five key areas where Ethernet-based industrial switches can power smart operations of the future.

1. High-performance infrastructure

Industrial Ethernet helps build a highly resilient, high-performance infrastructure. More than the enterprise, industrial operations rely on continuous uninterrupted operations to meet production targets and deliver services. Network downtime or interruption can result in decreased productivity leading to significant financial losses.

Today’s industrial Ethernet combines enterprise-grade performance and scalability with industrial-strength reliability and resilience. It features multi- and 10-gigabit interfaces to connect high-bandwidth devices and features high switching capacity to handle many connected devices. Industrial Ethernet also enables software-defined networking for greater flexibility, scalability and programmability in network infrastructure.

Several Ethernet-based redundancy protocols are used in industrial networks to provide high availability and fault tolerance. These include high-availability seamless redundancy (HSR) that uses redundant paths for Ethernet frames allowing for seamless failovers in case of link or node failures.

Similarly, parallel redundancy protocol (PRP) is another standard where the transmitting mode sends duplicate frames over two independent channels and the receiving node discards any duplicates it receives, ensuring data integrity and protecting against packet loss.

Technologies such as device level ring (DLR) connect devices in a ring and allow for simple and cost-effective implementation without additional switches. Resilient Ethernet protocol (REP) provides a sub-50 millisecond failover using a loop-free topology with backup paths.

2. Built-in cybersecurity

Cybersecurity is top-of-mind for industries. Visibility into connected devices, their interactions and vulnerabilities is the first step in securing industrial assets. This visibility can be gained from deep packet inspection (DPI) of network traffic. Traditionally, industrial networks have duplicated traffic from their switches to feed into offboard DPI servers. However, this leads to extra cost and complexity in the network. Today’s Ethernet provides a much simpler solution. Industrial switches can themselves perform DPI and obtain visibility and security insights as noted in Figure 1.

Visibility informs the second step in securing operations. Once you know the identity of assets and traffic patterns, you can define access policies that selectively allow or deny traffic between assets, control systems and external entities. These policies segment the network and place limits around groups of assets creating zones and conduits as required by the ISA/IEC62443 security standards, restricting unimpeded flow of potential malware through the operations.

While zones and conduits can be carved through extensive placement of firewalls, it is much simpler for the industrial Ethernet switches themselves to enforce access policies, thereby avoiding the extra cost and complexity.

3. Zero-trust network access

Industrial Ethernet can enable zero-trust network access (ZTNA). The ability to access industrial assets remotely, especially ones that may be geographically distributed, can be invaluable. Using it, operations staff, vendors or contractors can log in to those assets without costly site visits to monitor, debug, configure or otherwise manage them.

The solution for such access has traditionally been virtual private networks (VPNs). The drawback for VPNs is that they are an always-on solution with all-or-nothing access to operational technology (OT) assets. Industrial organizations are starting to deploy zero trust network access (ZTNA) solutions as alternatives to always-on VPNs.

ZTNA is a security service that verifies users and grants access only to specific resources at specific times based on identity and context policies. ZTNA solutions consist of a trust broker, typically a cloud service, that mediates connections between remote users and OT assets by working with a ZTNA gateway onsite, responsible for creating a communication path to the assets and an outbound connection to the trust broker, as shown in

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)