ABB DCS800 Drives

During installation the SDCS-CON-4 needs to be connected with the SDCS-PIN-51 using two shielded 16 pole flat cables. These cables connect terminals X12 with each other, as well as terminals X13. For easier access to the terminals in the control unit, connecting boards SDCS-CCB-4 or SDCS-CCB-5 are placed close to the lower end of the metal frame. When connecting X12 and X13 make sure the flat cables are marked at both ends, one with X12, the other with X13. Worst case put stickers on! Wedge the blank screen of the flat cable in position using the screen clamp, then place the plug into its socket.

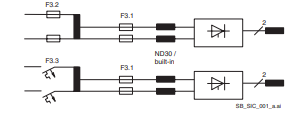

Fuses F3.2 and F3.3 are used as line protectors and cannot protect the field supply unit. Only pure HRC fuses or miniature circuit-breakers must be used. Semiconductor fuses will be tripped, for example, by the transformer’s inrush current.

Semiconductor fuses (F1) and fuse holders for armature circuit The converters are subdivided into two groups:

• Unit sizes D1, D2, D3 and D4 with rated currents up to 1000 A require external fuses.

• In unit sizes D4+, D5, D6 and D7 with rated currents from 900 A to 5200 A, branch fuses are internally installed (no additional external AC or DC fuses are needed). The fourth column of the table below assigns the AC fuse to the unit. In case the converter should be equipped with DC fuses, use the same type of fuse as on the AC side

EMC filters (E1) Filter in a grounded line (earthed TN or TT network) The filters are suitable for grounded lines only, for example in public European 400 VAC lines. According to EN 61800-3 filters are not needed in insulated industrial networks with own supply transformers. Furthermore they could cause safety risks in such floating lines (IT networks). According to EN 61800-3 filters are not needed in industrial zone (Second Environment) for DCS800 drives above 100 ADC rated current. For rated currents below 100 ADC the filter requirement is identical to Light Industry (First Environment). Three-phase filters EMC filters are necessary to fulfil the standard for emitted interference if a converter shall be run at a public low voltage line, in Europe for example with 400 VAC. Such lines have a grounded neutral conductor. ABB offers suitable three-phase filters for 400 VAC. For 440 VAC public low voltage lines outside Europe 500 VAC filters are available. Optimize the filters for the real motor currents: IFilter = 0.8 • IMOT max; the factor 0.8 respects the current ripple. Lines with 500 VAC up to 1000 VAC are not public. There are local networks inside factories, and they do not supply sensitive electronics. Therefore converters do not need EMC filters if they shall run with 500 VAC and more.

Converters size D4+ - D7 configuration using external field exciters DCF803, DCF804 Wiring the drive according to this diagram offers the highest degree of monitoring functions done by the drive. Field converters DCF803 / DCF804 are equipped with their own synchronization and must be supplied from independent mains supply voltage max. 500 V (single-phase or 3-phase).

Start, Stop and E-Stop control The relay logic is splitted into four parts: 1: Generation of the On / Off and Start / Stop command: The commands represented by K20 and K21 (latching interface relay) can also be generated by a PLC and transferred to the terminals of the converter either by relays, using galvanic isolation or directly via 24 V signals. There is no need to use hardwired signals. Transfer these commands via serial communication. Even a mixed solution can be realized by selecting different possibilities for the one or the other signal (see parameter group 11). 2: Generation of control and monitoring signals: Control the main contactor K1 for the armature circuit by the dry contact of DO8 located on the SDCS-PIN-4 or SDCS-POW-4. The status of motor (K6) and converter (K8) fans can be monitored by means of MotFanAck (10.06) and ConvFanAck (10.20). 3: Off2 (Coast Stop) and Off3 (E-stop): Beside On / Off and Start / Stop the drive is equipped with two additional stop functions Off2 (Coast Stop) and Off3 (E-stop) according to Profibus standard. Off3 (E-stop) is scalable via E StopMode (21.04) to perform stop category 1. Connect this function to the E-stop push button without any time delay. In case of E StopMode (21.04) = RampStop the K15 timer relay must be set longer than E StopRamp (22.04). For E StopMode (21.04) = Coast the drive opens the main contactor immediately. Off2 (Coast Stop) switches the DC current off as fast as possible and prepares the drive to open the main contactor or drop the mains supply. For a normal DC motor load the time to force the DC current to zero is below 20 ms. This function should be connected to all signals and safety functions opening the main contactor. This function is important for 4-Q drives. Do not open main contactor during regenerative current. The correct sequence is: 1. switch off regenerative current 2. then open the main contactor In case the E-stop push button is hit, the information is transferred to the converter via DI5. In case E StopMode (21.04) = RampStop or TorqueLimit the converter will decelerate the motor and then open the main contactor. If the drive has not finished the function within the K15 timer setting, the drive must get the command to switch off the current via K16. After the K16 timer has elapsed, the main contactor is opened immediately, independent of the drive's status.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)