GEInstallation and Maintenance Manual

install continuous monitoring systems. The term "protection" means that the

system can shut down machinery on alarm, without human interaction. These

systems include applicable transducers, each with its own dedicated monitoring

circuitry and alarm setpoints. The 3500 Monitoring System is the newest addition

to the family of continuous monitoring systems offered by Bently Nevada, LLC.

2.1 3500 Monitoring System

The 3500 is a full-feature monitoring system whose design incorporates the latest

in proven processor technology. In addition to meeting the above stated criteria,

the 3500 adds benefit in the following areas:

• Enhanced operator information

• Improved integration to plant control computer

• Reduced installation and maintenance cost

• Improved reliability

• Intrinsic Safety (IS) option

The following sections discuss these benefits in more detail.

2.1.1 Enhanced Operation Information

The 3500 design includes features to both enhance the operator's information

and present this information so that the operator may easily interpret it. These

features include:

• Improved data set

- Overall amplitude

- Probe gap voltage

- 1X amplitude and phase

- 2X amplitude and phase

- Not 1X amplitude

• Windows®-based Operator Display Software

• Data displayed at multiple locations

2.1.2 Improved Integration to Plant Control Computer

The 3500 improves integration to the plant control computer with:

• Communication Gateways supporting multiple protocols

• Time synchronized vibration and process information

2.1.3 Reduced Installation and Maintenance Costs

The 3500 system provides the following cost-saving features:

• Reduced cabling costs

• Downward product compatibility

• Improved space utilization

• Easier configuration

• Reduced spare parts

• Improved serviceability

2.1.4 Improved Reliability

The 3500 offers several features to improve system reliability.

• Redundant power supplies available

• Triple Modular Redundant (TMR) monitors and relay cards available

2.1.5 Intrinsic Safety Option

If you wish to monitor equipment that is located in hazardous atmospheres, the

3500 Monitoring System has a range of I/O modules with internal zener barriers.

These modules provide an Intrinsically Safe interface between the 3500 rack and

the transducers located in the hazardous area.

2.1.6 Multiple Output Interfaces

You can conveniently adjust monitor options (such as full scale ranges,

transducer inputs, recorder outputs, alarm time delays, alarm voting logic, and

relay configuration) in the field via software. Modular system design employs

plug-in components which allow easy servicing and expansion.

The following three independent interfaces are available with the 3500 system:

• Data Manager Interface (Transient Data Interface External or Dynamic

Data Interface External)

• Configuration/Data port

• Communications Gateway (support for Programmable Logic

Controllers, Process Control Computers, Distributed Control Systems,

and PC-based Control Systems)

These interfaces allow you to easily view monitored parameters and their

statuses in the following ways:

• System 1® Software

• Bently Nevada™ 3500 Operator Display Software

• Remote display panel

• DCS or PLC display

Convenient front panel coaxial connectors provide dynamic transducer signals

and allow you to connect diagnostic or predictive maintenance instruments.

2.2 Common Features

The common features of the modules in the 3500 rack include hot insertion or

removal of modules and external and internal termination of the wiring.

2.2.1 Hot Insertion or Removal of Modules

When performed properly, you can remove and replace any module while the

system is under power without affecting the operation of any unrelated modules.

If the rack has 2 power supplies, removing or inserting a power supply will not

disrupt the operation of the 3500 rack. See <<Section reverence: “Module

Installation in section 4 >> for the proper procedure.

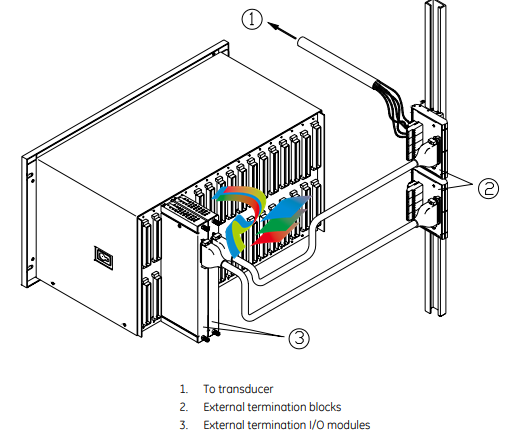

2.2.2 External and Internal Termination

External termination uses multi-conductor cables to connect the I/O modules to

the terminal blocks. These blocks simplify connecting many wires to the rack in

tight areas. External termination is not available on I/O modules with internal

zener barriers

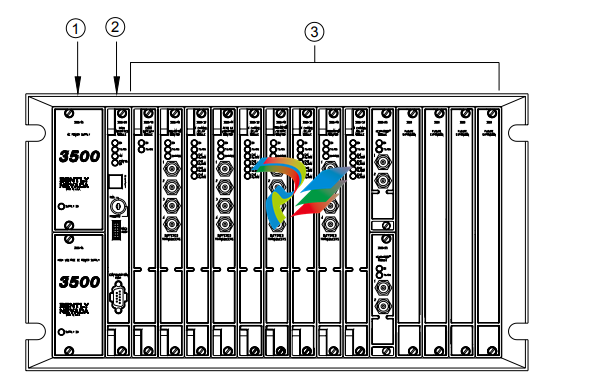

3500 System Components

The 3500 Monitoring System consists of modules that fit into a rack. Figure 2-3

shows a full-size 3500 system rack and system components. Note that the fullsize rack has 14 monitor slot positions. The Mini-rack (not shown) is similar, but

has 7 monitor slot positions to the right of the power supplies and Rack Interface

Module.

1. 1 or 2 power supplies

2. Rack Interface Module (standard, Transient Data Interface, (TDI), Triple Modular Redundant (TMR) and TMR TDI)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)