GEInstallation and Maintenance Manual

The Earthing Module is a full-height module that provides a low resistance

connection (must be less than 1 Ω) from the 3500 rack to the plant’s intrinsically

safe earth ground. The module operates in conjunction with the 3500 internal

zener barrier I/O modules. Your application will require 1 Earthing Module per rack

when internal barrier I/O modules are used.

2.4 Standard Rack Relay Options

You can configure the standard (or non-TMR) 3500 rack to have individual relays,

bussed relays, or a combination of individual and bussed relays.

2.4.1 Individual Relays

A rack with individual relays contains 1 or more relay cards for each monitor

module. You can configure the monitor and relay modules within a 3500 rack in

many ways.

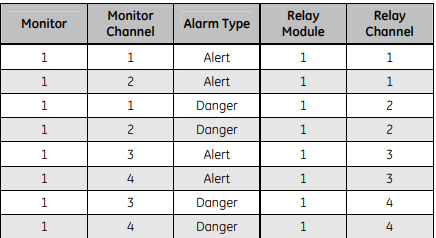

Example 1: The application uses 1 relay module 1 monitor module.

Table 2-1: 1 Relay Module Used With 1 Monitor Module

2.5 Intrinsic Safety — The 3500 Internal Barrier System

To provide Intrinsically Safe (IS) vibration and process variable monitoring, the

3500 system has a range of I/O modules with internal zener barriers. When you

install these modules in a 3500 rack with a 3500/04-01 Earthing Module, they

provide an integrated solution for explosion protection for approved Bently

Nevada transducer systems that are located within all classifications of

hazardous areas (surface industries other than mining).

2.5.1 3500 Internal Barrier System Restrictions

• You must install 1 earthing module in each rack in the internal barrier

system. The earthing module occupies 1 slot position in the rack when it

uses Internal Barrier I/O modules.

• You must change the grounding configuration of the 3500/15 Power

Supplies from the default factory setting. See the 3500/15 Operation and

Maintenance Manual (PN 129767-01) for instructions.

• You must isolate any RS-232 connection to any 3500 module. Monitors

that support RS232 connections include Rack Interface Modules,

Communication Gateways, and the 3500/95 PC Display. See the 3500/20

Operation and Maintenance Manual (PN 129768-01) for instructions. This

restriction does not apply to RS422 and RS485 connections to the rack.

Monitors that support RS422 and/or RS485 connections include the

3500/20, 3500/90, 3500/92, 3500/93, and 3500/95.

• You must not use the 3500/94 VGA Display in internal barrier systems.

• You must not use bussed transducers, as internal barrier systems do not

allow bussed transducers. See the TMR section of this manual for more

information.

2.5.2 3500 Internal Barrier System Features

• The earthing module supports dual IS Earth connections for cables with

cross-sectional areas up to 10 mm2. This module lets you test IS Earth

continuity online.

• The design of the internal barrier I/O modules provides the 2 inches (50

mm) of separation required between safe and hazardous area field wiring.

• The connectors for safe areas and hazardous areas have different field

wiring colors (green for safe and blue for hazardous) and connector

pitches. This helps to avoid incorrect field wiring installation.

• Quick connect/disconnect connectors simplify field wiring installation and

removal.

4.3 Replacing Modules

When replacing modules, whether main or I/O, you need not remove power from

the rack if the following procedures are followed. Refer to applicable steps in the

procedures above for removing or installing a module.

4.3.1 Main Modules

This assumes that you will replace only the main module of a monitor or power

supply. Before you remove any module, refer to the applicable manual to see how

this may affect rack behavior, and to identify any special handling requirements

that you may require for personal safety.

1. If necessary, upload and save the configuration of the module to be

replaced.

2. Remove the main module from the rack.

3. Install the new main module into the rack.

4. If necessary, configure the new main module.

5. Verify operation.

4.3.2 I/O Modules

This assumes that you will replace only the I/O module of a monitor or the PIM of

a power supply. Before you remove any module, refer to the applicable manual to

see how this may affect rack behavior, and to identify any special handling

requirements that you may require for personal safety.

1. If necessary, upload and save the configuration of the module to be

replaced.

2. Remove the main module from the rack.

3. Remove the field wiring from the I/O module.

4. Remove the old I/O module from the rack.

5. Install the new I/O module into the rack.

6. Connect the field wiring to the new I/O module.

7. Install the main module into the rack.

8. If necessary, re-configure the main module.

9. Verify operation

5.1 General Maintenance Instructions

You cannot repair the boards and components inside of 3500 modules in the field.

3500 rack maintenance consists of testing module channels to verify that they

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)