EMERSONOvation®-based Computerenhanced Rod Position Indication System

Nuclear Automation

Background

Westinghouse’s Ovation®-based computerenhanced rod position indication (CERPI) system

provides enhanced reliability, and reduced

operation and maintenance (O&M) costs. It

consistently provides an accurate indication of rod

position with the lowest installation cost possible.

This product design integrates more than 200

reactor years of documented lessons learned from

analog rod position system (ARPI), state-of-the-art

detector interface cards and Ovation controller

technology.

Functions include:

• Control rod position indication

• Control rod bottom alarm

• Detector temperature compensation

• Detector linearity compensation

• Operator alarm capability

• One-pass calibration

This is the most cost-effective alternative to the

complete replacement of the existing ARPI system.

Ovation®-based Computerenhanced Rod Position

Indication System

Description

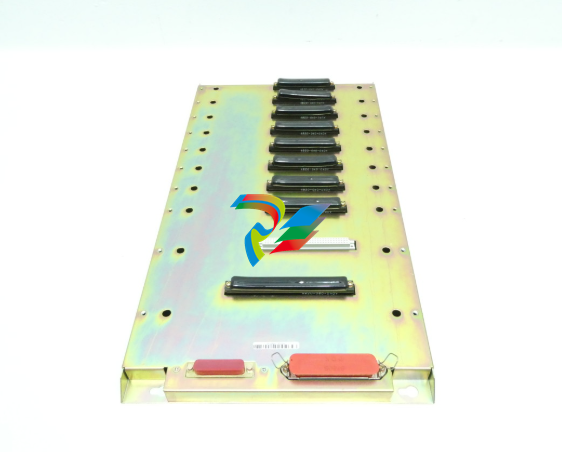

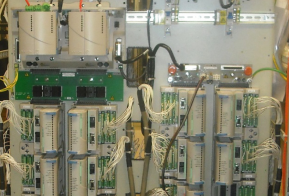

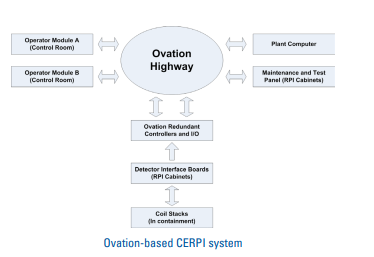

This system replaces the electronics portion of the

ARPI system within Westinghouse plants. The system

consists of a detector interface board for each rod,

redundant Ovation controllers and a new computerized

human-machine interface (HMI). This resolves the

issues of difficult and timely calibration and inaccurate

position indication for rods across the power range.

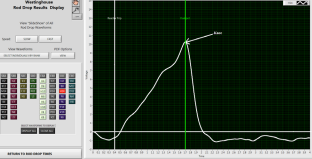

A rod drop test system is included as part of this

upgrade. Plant technical specifications require rod

drop time testing following a refueling outage so that

the rods insert properly and within the time-response

requirements of the plant’s safety analysis. This system

reduces critical path time by automatically analyzing

the data from each rod during a reactor trip and

displaying the results.

Features

• Low-cost installation

Utilizes the existing linear voltage transducer (LVTs),

eliminating as-low-as-reasonably-achievable concerns

and cost.

• One-pass calibration

The Ovation-based computer-enhanced rod position

indication system provides simplified, computercontrolled, non-interactive, zero and span (gain)

adjustments.

• Computer algorithm compensation

Detector ambient temperature and the non-linearity of

the LVT sensors have been compensated for utilizing

custom algorithms based on operating experience.

• Low detector crosstalk

Two different frequencies are used to drive rod LVTs,

minimizing the negative effect of detector crosstalk.

• Maintenance and Test Panel

Maintenance programs provide calibration history as

well as single, click-of-the-mouse, computer-controlled

calibration for zero and span settings.

• Operator Modules

Operator modules are provided to enhance the operator’s

capabilities. The rod information is directed to control

board-mounted flat panel displays and existing plant

computers.

• Control rod alarms

With the greatly improved accuracy of the system’s rod

position indication, dependable alarming for control

failures and rod bottom has been made available.

• Redundant Ovation controllers

Proven digital technology with guaranteed longterm support.

• Proven performance

This design was established by working closely with utility

staff and using ARPI lessons learned for more than 200

reactor years of operation. It has been well tested and has

replaced several ARPI systems. The results show that this

upgrade resolves the problem at a low-installation and

lifetime cost.

Benefits

• Elimination of deratings and callouts as a result of

limiting condition of operation entry from ARPIincreased profit

• Minimization of rod position indication calibration

in start up, resulting in reduced critical path time

• Accurate indication of rod position, resulting

in increased operator confidence

• Elimination of ARPI work-arounds, serving

to increase operator efficiency

• High reliability resulting in lower O&M cost

• Existing installations provide low-risk solution

• Direct replacement for ARPI and low-cost installation

• For rod drop testing, the ability to automatically

perform trending analysis that compares rod drops over

time

.png)