ABBCondition MonitoringMService V7.7 - User Manua MService V7.7 - User Manua [Document Type] ABB Ability™ Condition Monitoring for electrical systems - CMES User Manual MService Condition Monitoring V7.7 User Manual

NOTICE

This document contains information about one or more ABB products and may include a description of or a reference to

one or more standards that may be generally relevant to the ABB products. The presence of any such description of a

standard or reference to a standard is not a representation that all of the ABB products referenced in this document support all of the features of the described or referenced standard. In order to determine the specific features supported by a

particular ABB product, the reader should consult the product specifications for the particular ABB product.

ABB may have one or more patents or pending patent applications protecting the intellectual property in the ABB products described in this document.

The information in this document is subject to change without notice and should not be construed as a commitment by

ABB. ABB assumes no responsibility for any errors that may appear in this document.

Products described or referenced in this document are designed to be connected and to communicate information and

data through network interfaces, which should be connected to a secure net-work. It is the sole responsibility of the system/product owner to provide and continuously ensure a secure connection between the product and the system network and/or any other networks that may be connected.

The system/product owners must establish and maintain appropriate measures, including, but not limited to, the installation of firewalls, application of authentication measures, encryption of data, installation of antivirus programs, and so

on, to protect these products, the network, its system, and interfaces against security breaches, unauthorized access,

interference, intrusion, leakage, and/or theft of data or information.

ABB performs functionality testing on the products and updates that we release. However, system/product owners are

ultimately responsible for ensuring that any product updates or other major system updates (to include but not limited to

code changes, configuration file changes, third-party software updates or patches, hardware change out, and so on) are

compatible with the security measures implemented. The system/ product owners must verify that the system and associated products function as expected in the environment in which they are deployed.

In no event shall ABB be liable for direct, indirect, special, incidental or consequential damages of any nature or kind arising from the use of this document, nor shall ABB be liable for incidental or consequential damages arising from use of any

software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written permission from ABB, and the contents thereof must not be imparted to a third party nor used for any unauthorized purpose.

The software or hardware described in this document is furnished under a license and may be used, copied, or disclosed

only in accordance with the terms of such license. This product meets the requirements specified in EMC Directive

2014/30/EU and in Low Voltage Directive 2014/35/EU.

TRADEMARKS

MNS and MNS iS a registered trademark.

Microsoft, Windows 2008, Windows 7, and Windows 8 are registered trademarks of Microsoft Corporation.

Product names of other products are registered trademarks of their manufacturers.

This document relates to the MService Release 7.7 and following.

All rights to copyrights, registered trademarks, and trademarks reside with their respective owners.

Copyright © 2019 ABB.

All rights reserved.

Release: July 2019

Document Number: 1TGC910104

Revision: M0202

1 General

1.1. Target Group

MService is the embedded Condition Monitoring device for ABB Low Voltage Switchgears. Audiences

of this manual are service technicians and switchgear operators on site.

The document describes how to get the device installed in a switchgear network, and how to operate

it using the web-based user interface.

The reader shall be familiar with the terms and concept of ABB MNS Low Voltage Switchgear.

1.1 Use of Warning, Caution, Information and Tip icon

This publication includes Warning, Caution, and Information icons where appropriate to point out

safety related or other important information. It also includes Tip icons to point out useful hints to the

reader. The corresponding symbols should be interpreted as follows:

The electrical warning icon indicates the presence of a hazard that

could result in electrical shock.

The warning icon indicates the presence of a hazard that could result in

personal injury.

The information icon alerts the reader to pertinent facts and conditions.

Although Warning notices are related to personal injury, and Caution notices are associated with

equipment or property damage, the operation of damaged equipment could, under certain operational conditions, result in impaired process performance leading to personal injury or death. It is,

therefore, imperative that you comply fully sigh all Warning and Caution notices.

1.2 Terminology

List of the terminology, acronyms, abbreviations and definitions that the document uses.

Abbreviation Term Description

Eth. Ethernet Ethernet is a local area network (LAN) technology.

The Ethernet standard specifies the physical medium, access control rules and the message

frames.

HMI /

WebHMI

Human Machine Interface

Hard- and Software which implements the user interface.

A WebHMI is a SW providing the HMI in an Internet

web browser

LVS Low voltage switchgear

Low voltage switchgear assembly built in accordance with IEC 61439-1.

MCC Motor Control Centre Common term for switchgear used for motor control and protection.

MNS Modular Low Voltage Switchgear family from ABB

UMC /

M10x

Universal Motor Controller

An intelligent motor controller for 3-phase AC induction motors combining the two classical functions of motor protection and motor management in a single device plus offering diagnostic

and fieldbus communication.

MTQ22-FBP The MTQ22-FBP Ethernet adapter module allows

the connection of FBP devices to Ethernet

MNS iS The integrated intelligent switchgear solution

from ABB.

MStart

MFeed

MControl

MConnect

MSpeed

MLink

MView

MNavigate

MNS iS components integrated in the switchgear,

see the MNS iS System Guide for technical details

OPC Open Platform Communications

The industrial de-facto standard for exchange of

information between components and process

supervision and monitoring applications using

TCP/IP based networks

OPC ID OPC Network identifier

The OPC ID configured for MLink devices and for

the OPC Server defines, which MLink devices are

communicating to which OPC server. This defines

a kind of logical sub-net within a certain IP network.

TCP/IP Transmission Control

Protocol / Internet

Protocol

TCP/IP is a high-level connection oriented, reliable, full duplex communication protocol developed for networked integration of the heterogeneous computer systems.

NAMUR NAMUR is an international user association of automation technology in process industries.

1.3 Related Documentation

[1] 1TGC910001B0204 MNS iS System Guide

[2] 1TGC910232M0201 OPC Server Interface Manual V7.7

[3] 1TGC910221M0201 MNS iS Interface Manual Web Interface_Rel_7.0

[4] NE107 (2006-02-10) NAMUR Recommendation Self-Monitoring and Diagnosis of Field Devices

1.4 Related System Version

The content of this document is related to MService V7.7 and onwards

1.5 Cyber Security

Following cyber security-based recommendations must be considered using MService device in an industrial Ethernet network environment:

• MService shall be connected to an isolated network in general. If MService is connected to a

plant network a firewall shall be considered to control access to MService web-based user interface.

• Insertion of a USB drive / pen-drive / stick into a USB port of MService shall be prevented at any

time except connecting an external hard-disk for data backup purpose. Inserting a faulty USB

drive (e.g. with faulty USB-HID(*) descriptor) can lead to a stop of MService functionality. In such

a case MService will not record any data from connected field devices any longer and a device

reboot is required.

To prevent an unrestricted access to the USB ports of MService USB Port Locks shall be used.

These port locks reduce the risk of data leakage, data theft and unauthorized uploads with a

software-free solution that physically blocks USB ports from unauthorized access. There’s even

an option to block multiple adjacent ports with one lock and allow continued secure use of authorized USB devices.

• User must log-off from MService when leaving the workplace to prevent another person using

the active login account. The log-off button must be used in this case as closing the Web

browser will not terminate the active web-session.

(*) HID - Human Interface Device

2 System Overview

2.1 Product Concept

The MService device implements an innovative approach to condition monitoring: The supervision of

the performance and health status of a MNS and MNS iS switchgear are made possible with a smallscale and easy-to-use embedded industrial PC.

The MService implements the whole condition monitoring concept from collecting field level real-time

data to performing assessment algorithms. Based on that, it is possible to work out a prognosis of

developing situations and prompting the operator for action. However, if the situation continues and

results in a tripping or failure, the MService offers clear diagnosis for fast problem resolution.

MService targets two main application scenarios:

• Customer’s staff can use the device for performance analysis and continuous support of

maintenance planning for MNS and MNS iS system, with MService installed as permanent part of

the switchgear.

• ABB’s service personnel use the device to place it in a customer’s switchgear to support customer decisions in keeping the switchgear in good condition by collecting data for a certain

time and derive an assessment on the switchgear performance and operational status.

To fit to these scenarios, the MService employs a small-scale, compact approach to enable fast commissioning and ease of use.

2.2 Supported Functions

MService Condition Monitoring covers the following main functions:

• Collection of operational data of the supervised modules

• Collection of all alarms and trips generated in the supervised modules

• Collection of maintenance warnings derived from additional assessment logic related to the supervised modules.

• Display of the MNS or MNS iS system structure highlighting modules signaling problems

• Display of historical data in trend displays

• Detailed information on the identification, location, and type of supervised modules

• Online supervision of temperature or power loss related problems within individual cubicles.

MService can supervise all modules in MNS and MNS iS, which are connected to the internal switchgear

communication bus. This includes:

• Motor starter and feeder modules (all sizes), which are equipped with measuring and communication electronic device MControl

• Motor starter and feeder modules (all sizes), which are equipped with intelligent device, UMC

and M10x, communicates to MLink.

• Circuit breakers connected to the switchgear communication with the interface MConnect

• Circuit breakers connected to the switchgear communication with the interface MLink

Excluded from supervision in MService are all modules not connected to the internal switchgear communication such as MSpeed (Variable Speed drives in MNS iS) and conventional modules.

In general, MService supports all types of modules which are also accessible in MView.

MService firmware version 7.7 is extended to MNS - Intelligent Switchgear,

UMC100/UMC100.3/M10x-M/Emax/Emax2 connects to MLink. In order to configure MService to MNS – Intelligent Switchgear, MNS Engineer, MNavigate and

MNavigate Plus version release 7.7 onwards shall be used. See more details in

1TGA710500 INSUM Upgrade Guideline UMC100 and 1TGA710501 INSUM Upgrade

Guideline M10x

2.3 Hardware characteristics

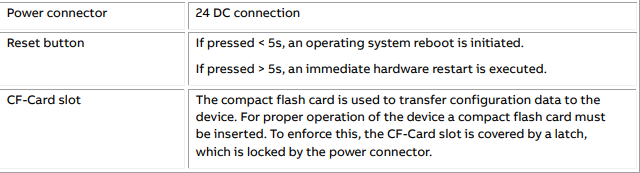

Fig. 2: MService interfaces

All interfaces of the MService devices are in the front plate. The following interfaces are relevant for the

operation of the device:

3.2 MService mounting in MNS and MNS iS Cubicle

The MService device is placed in the control compartment of a MNS iS switchboard. The device is mechanically held by means of a device support (single support 300mm for MService only, double support

400mm for MLink/MService combinations).

The electrical power (24V DC) is typically taken from the control voltage distribution bar in the same

compartment

The MService is installed on a MLink mounting kit which is housed in an 8E withdrawable

module compartment of the MNS cubicle. The MLink mounting kit is capable to support

mounting for two MLink and one MService within an 8E compartment. The installation instruction and the required part of the mounting kit can be found in the “1TNA810039 -- Manufacture Instruction – Installation of MService and MLink” .

3.3 MService in MNS and MNS iS network

MService collects the operational data from the switchgear using the built-in OPC Server. Therefore,

the device must be connected to the switchgear network. All MService and MLink devices must be configured appropriately.

Different possibilities exist, how to set up the network, the most common are depicted in the following sections.

Do not connect several MService devices to the same network before the correct network

settings are downloaded and activated. A failure of the network communication may be

result if ignoring this.

Since the design of computer networks is in most cases governed by company rules on site, ABB provides the required network equipment only on special request.

The network sketches in the following sections always assume, that all devices are connected to a network switch forming a local area network (LAN) depicted by the grey line.

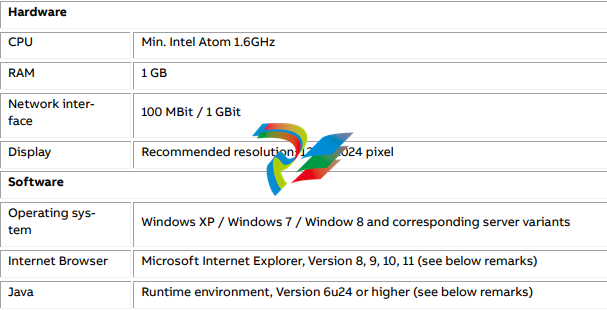

3.3.1 Client PC requirements and configuration recommendations

The MService WebHMI uses standard web technologies limiting the software requirements on the client PC to a minimum. To use the web interface of the MService device a standard PC is needed with

the following minimum characteristics

Microsoft Internet Explorer 11

Using version 11 of Internet Explorer requires Java Runtime Environment to be upgraded to at least

Version 7 update 55.

Java Runtime Environment

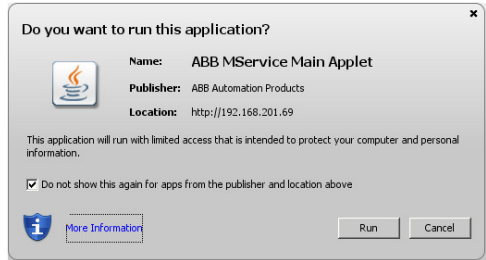

The main display of the MService WebHMI is implemented as Java applet. Starting with Java 7, Oracle

introduced a security check, asking the user to run the applet. The Java runtime shows a

dialog, asking for permission to run the applet. The Java applet is digitally signed

and the user can select to accept the signature. If the certificate is accepted, the

security dialog is not shown again for this MService and on this PC.

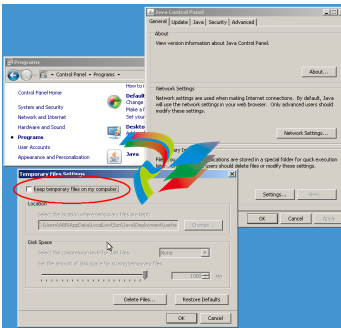

Furthermore, it is recommended to configure the Java Runtime environment in the following manner:

• Disable “Keep temporary files on my computer”

.png)

.png)

.png)