ABB 3BSE025347R1 CI854 DP-V1 Interface Module

ABB 3BSE025347R1 CI854 DP-V1 Interface ModuleTechnical Overview and Integration GuideMay 15, 2025 | Industrial Automation | |

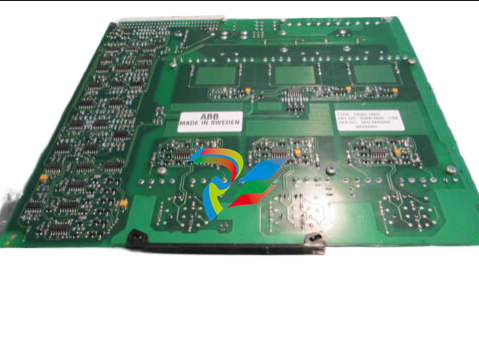

| PROFIBUS DP-V1 Communication InterfaceThe ABB CI854 DP-V1 Interface Module (3BSE025347R1) is a communication interface designed for the ABB 800xA control system. It enables seamless integration with PROFIBUS DP networks, providing high-speed communication for industrial automation systems. This module functions as a PROFIBUS-DP master, controlling slave devices on the network with support for line redundancy and master redundancy capabilities, ensuring uninterrupted communication in critical applications. |

IntroductionThe ABB CI854 DP-V1 Interface Module (part number 3BSE025347R1) is a specialized communication interface designed for industrial automation systems that require reliable PROFIBUS connectivity. This module serves as a critical component in the ABB 800xA control system architecture, facilitating seamless integration with PROFIBUS DP networks and enabling high-speed data exchange between controllers and field devices. In today's industrial environment, where network integrity and system availability are paramount, the CI854 module stands out with its robust design and redundancy capabilities. This technical article provides a comprehensive analysis of the CI854's architecture, functionality, integration methods, and application scenarios to assist automation engineers in leveraging its capabilities effectively. | |

Technical Specifications | |

| Specification | Value |

|---|---|

| Product Number | 3BSE025347R1 |

| Model Type | CI854 DP-V1 |

| Manufacturer | ABB |

| Product Family | ABB Advant-800xA |

| Communication Protocol | PROFIBUS DP-V1 |

| Baseplate | TP854 (3BSE025349R1) |

| Physical Dimensions | 216 × 49.5 × 72 mm (with baseplate) |

| Weight | Approximately 0.2 kg |

| Transmission Rate | 9.6 kbit/s to 12 Mbit/s (auto-detection) |

| Maximum Bus Length | Dependent on transmission rate (100m @ 12Mbit/s to 1200m @ 9.6kbit/s) |

| Maximum Slave Devices | Up to 125 per channel |

| Operating Temperature | 0°C to +55°C |

| Standard Compliance | EN 50170, IEC 61158 |

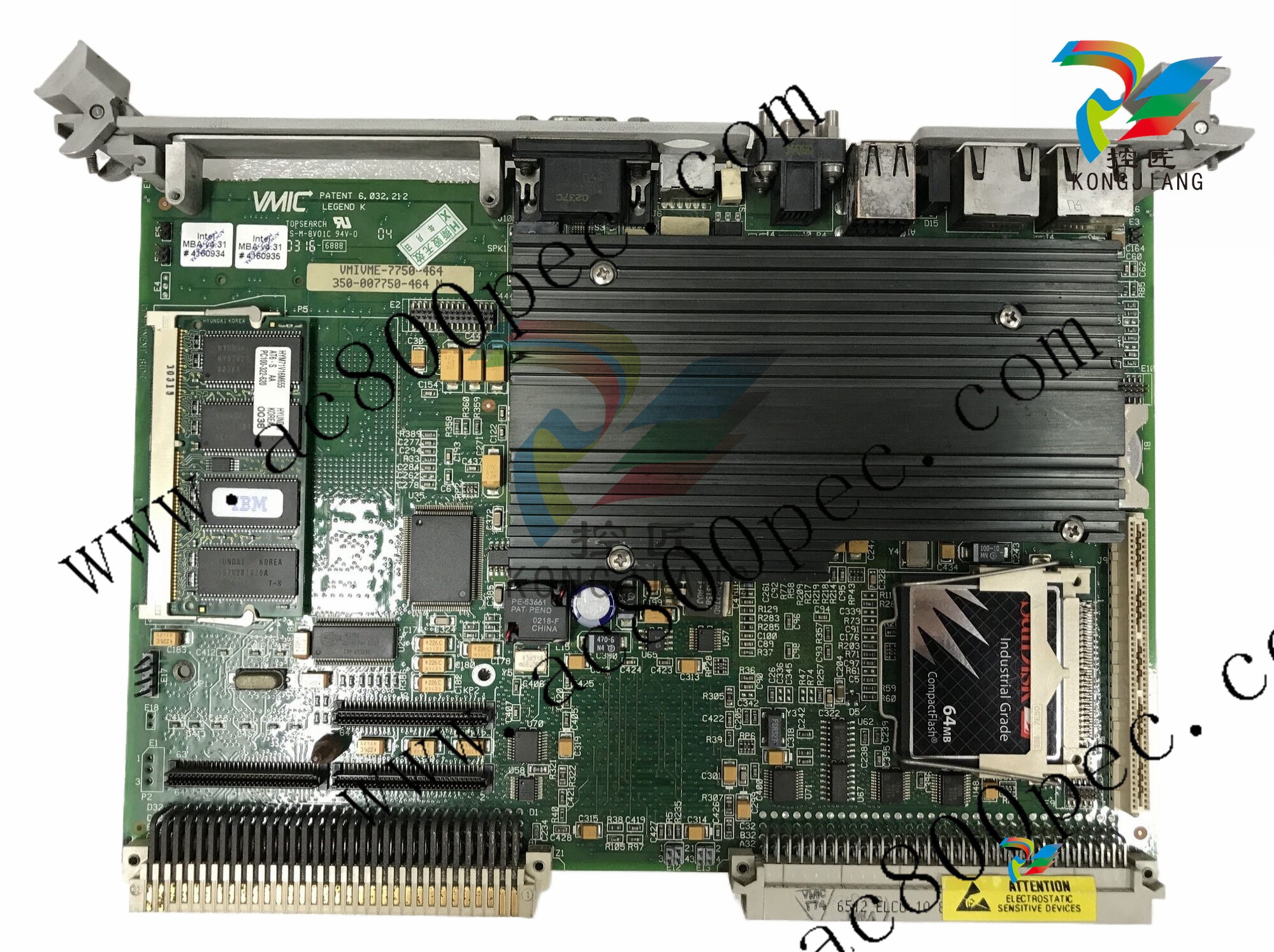

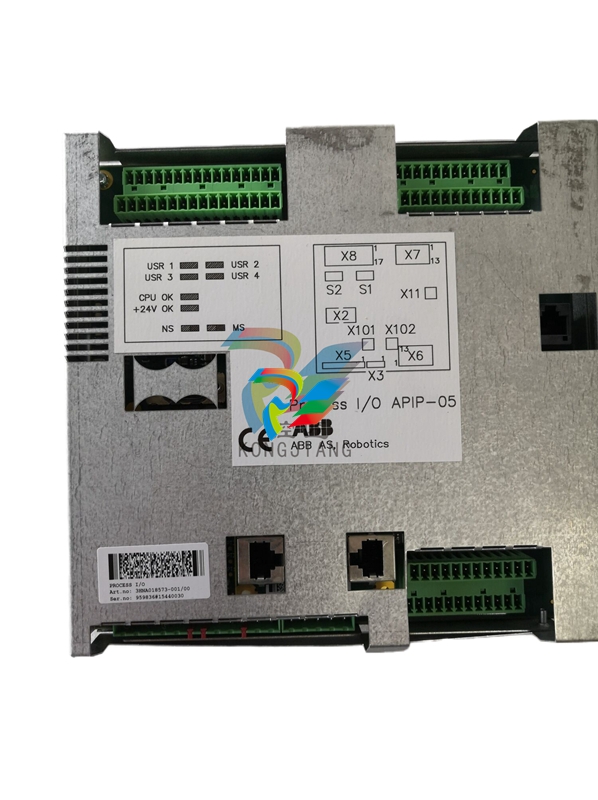

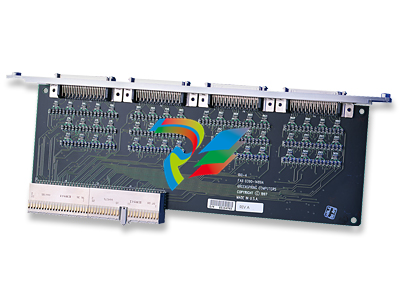

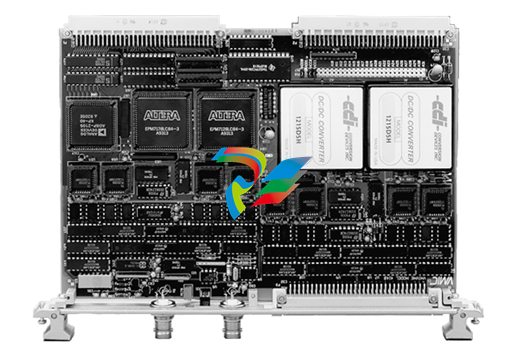

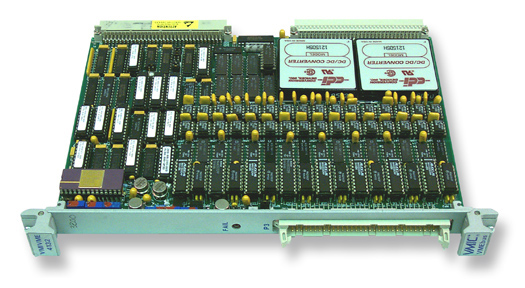

Hardware ArchitectureThe CI854 module consists of two primary components: the interface module itself and the TP854 baseplate. The baseplate serves as the mounting and connection point, featuring two female DB9 connectors for PROFIBUS DP communication lines. It includes a code lock mechanism that prevents installation of incompatible modules, ensuring system integrity. The interface module houses the processing unit, memory, and communication controllers necessary for PROFIBUS master functionality. Status LEDs provide visual indication of module state, communication status, and error conditions, facilitating quick diagnostics during operation and commissioning. Key Architectural Features

|

Functional CapabilitiesThe CI854 module functions as a PROFIBUS DP-V1 master, enabling communication with a wide range of PROFIBUS-compatible devices. Its implementation of the DP-V1 extension provides enhanced functionality beyond basic DP capabilities, including acyclic communication for parameterization, operation, visualization, and alarm handling. PROFIBUS DP-V1 Master FunctionalityAs a PROFIBUS master, the CI854 module manages the PROFIBUS network, initiating communication with slave devices and coordinating data exchange. It handles tasks such as:

|

Redundancy CapabilitiesOne of the distinguishing features of the CI854 module is its comprehensive support for redundancy, which is crucial for high-availability systems. The module supports multiple redundancy configurations:

These redundancy capabilities make the CI854 module particularly suitable for critical applications where system availability is paramount, such as continuous process industries, power generation, and safety-critical operations. |

Integration and ConfigurationIntegrating the CI854 module into an automation system requires careful planning and configuration. The following sections outline the key considerations and steps for successful implementation. Hardware InstallationThe CI854 module is designed for installation in ABB's 800xA control system environment. The physical installation process involves:

Proper grounding and shielding of PROFIBUS cables are essential for reliable operation, particularly in environments with electromagnetic interference. The 800xA system provides guidelines for cable routing, shielding, and grounding that should be followed to ensure communication integrity. |

Software ConfigurationConfiguration of the CI854 module is performed through ABB's Control Builder software, which provides the tools necessary for defining the PROFIBUS network structure, slave device parameters, and communication settings. The configuration process involves several key steps:

|

Application ScenariosThe CI854 module's capabilities make it suitable for a wide range of industrial applications. Here are some typical scenarios where this module provides significant value: Process Industry ApplicationsIn continuous process industries such as chemical, petrochemical, and pulp & paper, the CI854 module serves as a reliable bridge between the control system and field devices. Its redundancy capabilities ensure uninterrupted production, while its support for acyclic communication enables online device parameterization without process disruption. Power Generation and DistributionPower generation facilities require high-availability control systems with robust communication capabilities. The CI854 module's redundant communication architecture contributes to system resilience, while its support for PROFIBUS DP-V1 enables integration with intelligent electrical devices, motor control centers, and protection relays. Manufacturing and Discrete AutomationIn manufacturing environments, the CI854 module enables integration of various automation components such as motor drives, pneumatic systems, and robotic controllers. Its high-speed communication capabilities support the deterministic response times required for precise motion control and synchronization. |

Maintenance and TroubleshootingEffective maintenance and troubleshooting are essential for ensuring reliable operation of the CI854 module and its associated PROFIBUS network. The 800xA system provides several tools and features that facilitate these activities:

|

Network Design Best PracticesProper network design is crucial for ensuring reliable PROFIBUS communication. When implementing the CI854 module, consider these best practices:

|

Future Trends and CompatibilityWhile PROFIBUS remains a widely used industrial fieldbus protocol, the industrial automation landscape continues to evolve toward Ethernet-based communication technologies. Understanding the CI854 module's position in this evolving landscape helps inform long-term automation strategies. Migration PathsABB provides several migration paths for systems using CI854 modules to transition toward newer communication technologies:

|

ConclusionThe ABB 3BSE025347R1 CI854 DP-V1 Interface Module represents a robust solution for PROFIBUS integration in industrial automation systems. Its comprehensive feature set, redundancy capabilities, and seamless integration with the 800xA control system make it a valuable component for applications requiring reliable field device communication. By understanding the module's architecture, functionality, and integration requirements, automation engineers can effectively leverage its capabilities to build resilient and efficient control systems. As industrial networks continue to evolve, the CI854 module's support for the widely adopted PROFIBUS standard ensures compatibility with a vast ecosystem of automation devices, protecting investments and facilitating future expansions. |

.png)