Technical Overview: Siemens 6FC5403-0AA20-1AA1 Industrial Operator Interface

Installation & Connection

Connection Options

The SINUMERIK HT 8 can be connected to the control system in two primary ways:

Connection Modules: Direct integration with the control cabinet using specialized connection modules

Connection Boxes: External connection points that can be strategically placed around the machine

Both connection methods maintain the integrity of the emergency circuit and ensure proper system integration.

System Integration

When connected to a SINUMERIK control system, the HT 8 terminal:

Automatically identifies itself to the control system

Reads the configuration from the HMI main panel

Adapts to the emergency circuit configuration

Displays the corresponding user interface of the connected SINUMERIK NCU/PCU

Provides immediate access to programmed customer-specific applications

Important Safety Considerations

The handheld terminal includes critical safety features that must be properly integrated into the machine's safety systems:

Emergency stop button must be correctly wired into the machine's emergency circuit

Three-position enabling buttons must be properly configured according to safety standards

Connection and disconnection procedures must follow manufacturer guidelines to prevent unintended machine movements

The system should be configured to require deliberate acknowledgment before resuming operation after reconnecting the terminal

User Interface & Operation

The SINUMERIK HT 8 provides an intuitive and responsive user interface that replicates the functionality of the main HMI panel while adding mobility. Key interface elements include:

Touch Screen Functionality

Intuitive touch operation for menu navigation

Direct input of values and parameters

Visual feedback for touch interactions

Context-sensitive control elements that adapt to the current operation

Physical Control Elements

Dedicated machine control keys for common functions

Axis traversing keys for direct movement control

Precision handwheel for fine positioning

Emergency stop button for immediate machine shutdown

Dual three-position enabling buttons (for left or right-handed operation)

Enabling Button Operation

The three-position enabling buttons operate according to this safety principle:

Position 1 (Released): Machine movement disabled (safe state)

Position 2 (Middle/Pressed halfway): Machine movement enabled

Position 3 (Fully Pressed): Machine movement disabled (panic state)

This design ensures that both deliberate release and panic-grip reactions result in the machine stopping, providing a fail-safe operation method.

Maintenance & Support

To ensure optimal performance and longevity of the Siemens 6FC5403-0AA20-1AA1 handheld terminal, regular maintenance is recommended:

Periodic inspection of cable integrity and connection points

Cleaning of the touch screen display using appropriate industrial-grade cleaners

Verification of enabling button and emergency stop functionality

Checking handwheel operation and calibration

Ensuring proper response of all control keys

Testing system integration and emergency circuit functionality

Common Troubleshooting

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Terminal not recognized by system | Connection issue, interface error, incompatible configuration | Verify cable connections, check system compatibility, restart control system |

| Touch screen unresponsive | Calibration drift, screen damage, software issue | Recalibrate touch interface, check for physical damage, verify software version |

| Handwheel not functioning | Connection issue, encoder failure, configuration problem | Check internal connections, verify encoder functionality, review system parameters |

| Enabling buttons not working | Safety circuit issue, button mechanism failure | Inspect safety circuit integration, test button mechanism, verify wiring |

| Display showing incorrect interface | Configuration mismatch, software incompatibility | Verify system configuration, update software if needed, check connection type |

Replacement & Sourcing Options

When sourcing the Siemens 6FC5403-0AA20-1AA1 handheld terminal or related components, consider these options:

Industrial Automation Specialists

Companies specializing in automation components with expertise in Siemens CNC systems and parts.

Offerings: New units, refurbished equipment, repair services

CNC System Integrators

System integration companies that provide comprehensive solutions for CNC equipment including replacement parts.

Offerings: Technical support, installation services, compatible accessories

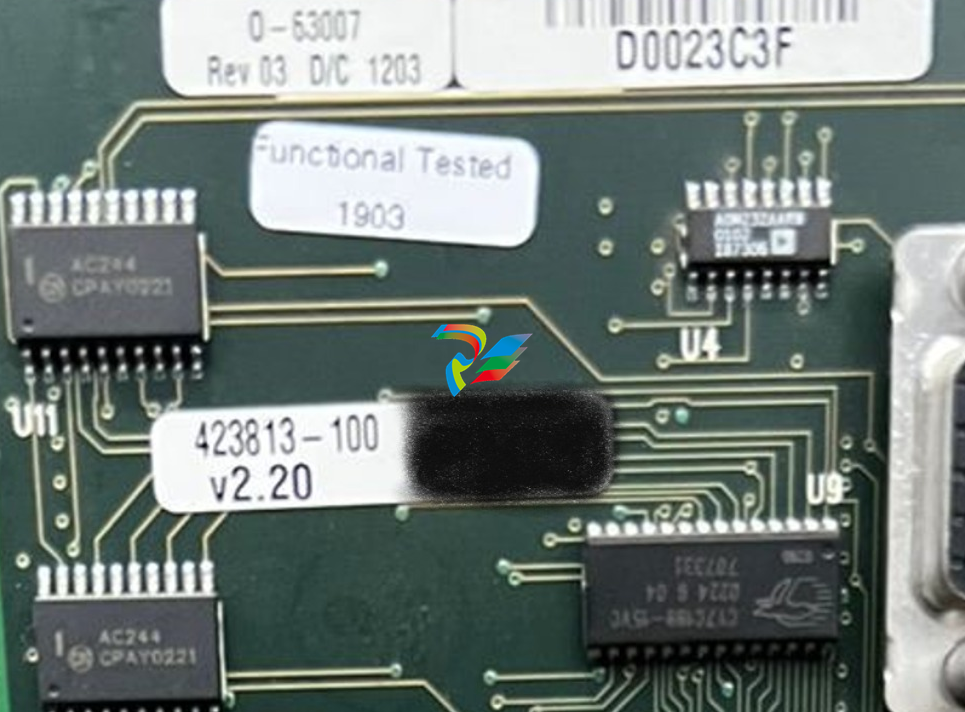

Industrial Electronics Repair Centers

Specialized facilities that repair and refurbish industrial control components including operator interfaces.

Offerings: Repair services, exchange programs, testing certification

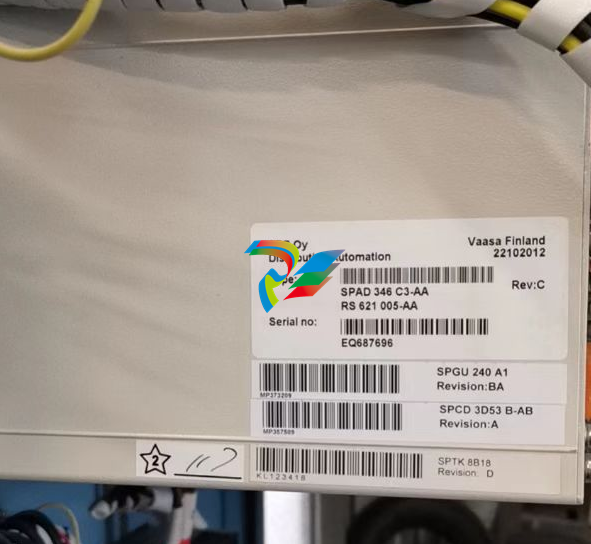

Important Sourcing Considerations

When selecting a supplier for Siemens industrial components:

Verify the warranty terms and duration offered

Confirm that refurbished units undergo comprehensive testing

Check compatibility with your specific SINUMERIK control system version

Consider the availability of technical support and documentation

Verify that replacement parts meet all required safety standards

.png)