SAM Lyngsø MarineDMS2100i Bridge Manoeuvring System MAN B&W ME/ME-C Engines User Manual

Diesel Manoeuvring System, DMS2100i Page 6 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

1. DMS2100i Introduction

The Diesel Manoeuvring System - DMS2100i is a Bridge Manoeuvring System used for remote

control of a ship’s Propulsion Line, with a MAN B&W two-stroke low speed ME-Engine connected to a Fixed Pitch Propeller (FPP).

The DMS2100i is operated by means of Telegraph Levers and standard DMS2100i Panels with

build in four-line display.

The DMS2100i is operated as a completely independent stand-alone system, with all information and internal alarms displayed on the DMS Operator Panels.

When the DMS2100i are delivered together with a Lyngsø Marine Universal Monitoring System, UMS2100 alarm system or as an integrated part of the Universal Control System

UCS2100, the systems can be interconnected by means of a communication network, so that

alarms, indications and measurements values from the DMS2100i can be displayed on the

Graphical Operator Station (GOS) and alarm Panels in the Alarm and Control System also.

The DMS2100i can be configured to provide complete control for:

· Main Engine Remote Start/Stop from Bridge

· Start Blocking indications

· Main Engine Setpoint System

· Main Engine Shutdown Indications from ME Safety System

· Main Engine Slowdown System

· Main Engine Speed Measurement and Indication

· Control Transfer for Bridge/ECR/Local Change-over

· Sub-telegraph Control with Finished With Engine (FWE), Stand-by and Sea-mode

· Main Engine Running Mode Selector (Economy mode, Emission Mode etc.)

· Dual Serial Interface to the ME-Engine Electronic Control System (ECS)

· Alarm Announcement and Indication

The DMS2100i can be extended with the following options:

· DPS2100 Engine Safety System (independent system for Shutdowns and overspeed)

· Communication Telegraph System for Bridge order communication to ECR/Local

· Bridge Wing Control (Wing Panels Optional) and Electric Shaft on Telegraph Levers

· Manoeuvring Order Printer integrated in the system

· Integration with Lyngsø Marine Alarm and Control System

· Serial interface (Modbus) to other types of ships alarm system

This User Manual gives an overview of the hardware and describes the functionality of the

DMS2100i Bridge Manoeuvring System, and includes wiring diagrams etc.

Also the Monitoring and Control System, the Safety System, the Telegraph Lever System with

Electric Shaft for the Bridge Wings and other related system and options are described to give a

complete overview of the remote control system.

1.1 References

[1] MBD ME-Engine Interface & Requirements to External Control Systems

[2] MBD ME-Engine Engine Control System – I/O Specification

[2] MBD ME-Engine Engine Control System – Available Options

[2] MBD ME-Engine Serial Interface – Requirement Specification

[2] Propulsion Control System, PCS2100, System Description

[3] Diesel Protection System, DPS2100, System Description and User Manual

[4] Universal Monitoring System, UMS2100, System Description and User Manual

[5] Universal Control System, UCS2100, System Description and User Manual

1.2 Definitions and Abbreviations

AAM Analog Output Module type 401

AEM Analog Input Module type 402

AI Analog Input

AO Analog Output

BAP Basic Alarm Panel

BRG Bridge

BT Bow Thruster

CPP Controllable Pitch Propeller

DG Diesel Generator

DI Digital Input

DO Digital Output

DMS Diesel Manoeuvring System - Bridge Manoeuvring System

DNM Dual STELLA NET communication interface Module

DPS Diesel Protection System - Engine Safety System

DSN Dual STELLA NET communication interface

DZM DrehZahl relais Module - speed relay module type 402

ECR Engine Control Room

ECS Electronic Control System for MBD ME-Engine

EMG Emergency

ENT Enter key

ER Engine Room

ESC Escape key

ESS Engine Safety System

EXH Exhaust

FIM 405 Filter Module for 24 Vdc Power Supply

FPP Fixed Pitch Propeller

GOS Graphic Operator Station

I/O Input/Output

I/P Current to Pressure converter

IOM Input Output Module - type 402

LC Local Control

LCD Liquid Crystal Display

LED Light Emitting Diode

LOP Local Operator Panel

LP Low pass Filter

LM Lyngsø Marine

MAM MIC40 Input/Output Adapter, Gamma to digital I/O modules

Diesel Manoeuvring System, DMS2100i Page 9 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

MBD MAN B&W Diesel

ME Main Engine

MEP Mean Effective Cylinder Pressure

MIC40 Input/Output Adapter, Gamma to digital I/O modules

MSB Main Switch Board

MXM Multiplexer Module type 402 (16 channel analog input)

NA Not Applicable

PCC Propulsion Control Cabinet

PCS Propulsion Control System

PLC Programmable Logic Controller - Gamma computer

PMS Power Management System - ships generator control system

PS Port Side

PTO Power Take Off

REM Binary input and relay output module type 401

RPM Rotations Per Minute

SB Star Board side

SG Shaft Generator

SHD Shutdown

SIM Serial Input/Output Interface Module

SIO Serial Input/Output Communication

SLD Slowdown

ST Stern Thruster

TAM Tacho Adapter Module type 401

TC Turbo Charger

UPS Uninterruptible Power Supply

UMS Universal Monitoring System - ships alarm system

UCS Universal Control System- ships alarm and control system

Diesel Manoeuvring System, DMS2100i Page 10 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

2. DMS2100i System Overview

The DMS2100i control functions for a Propulsion Line existing of a MAN B&W two-stroke

low speed ME-Engine with Fixed Pitch Propeller are handled by one DMS2100i Gamma PLC

mounted in the DMS control cabinet, together with the units for a DPS2100 Engine Safety System.

The Main Engine Safety System is completely independent of the DMS. The Main Engine may

be equipped with a standard Safety System from the Main Engine manufacturer. If the Main Engine manufacturer supply does not include a Safety System, the DMS can be delivered together

with an independent Diesel Protection System, DPS2100 Safety System.

Other Gamma PLC's in the UMS/UCS2100 Alarm and Control System handles the alarm and

monitoring part of the machinery components controlled by the DMS2100i.

In case that alarms from the Main Engine are connected to the DMS Gamma, it must be alarms

relevant for the Main Engine controlled by that particular DMS Gamma only, because they will

be displayed as DMS alarms on the DMS Panels, such as e.g. alarms initiating a Slowdown/load reduction, startblockings etc.

The DMS2100i and the UCS2100 Alarm and Control system are independent systems, each

with its own Gamma PLC’s, only connected by a network to transfer alarms and information to

the GOS and printers (Manoeuvring Order Printer). The network will also be used for automatic operation of the Power Management System (PMS) e.g. in case of mode change to/from a

mode where the SG is connected to a Bow Thruster (BT) and/or Stern Thruster (ST).

Slowdowns for the Main Engine and optional RPM up/down signals from the Power Management System (for frequency control, load sharing and synchronising purposes) are transferred as

hardwired signal lines for safety reasons. The Slowdown inputs to the DMS2100i are defined

as supervised inputs, i.e. cable break can be detected.

All hardware component and logic circuitry of the DMS2100i and the UCS2100 Alarm and

Control System is independent. That means it will still be possible to control the propulsion

machinery even in case of a total breakdown of the Alarm and Monitoring System.

The power supply for the DMS2100i as well as the DPS2100 and UCS2100 must be Uninterruptible Power Supply (UPS) protected. There must be a separate fuse for the DMS2100i

Gamma, the DPS PLC and the remaining hardware connected to this system.

The following part of the remote control system are described in this section:

· DMS2100i Main Cabinet (Gamma PLC, I/O Modules etc.)

· DMS Panels for remote control of the propulsion machinery

· ECR Components for Manual ECR Control of the propulsion machinery

· Local Operator Panel for Local Control of the propulsion machinery

· DPS2100 Engine Safety System

· Telegraph Lever System

· Electric Shaft for Bridge Wings control

· Communication Telegraph System

· Main Engine Speed Measurement

Diesel Manoeuvring System, DMS2100i Page 11 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

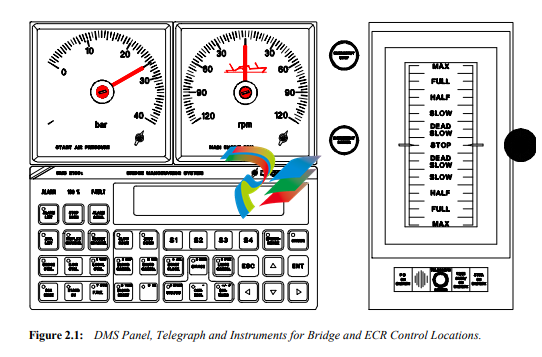

2.1 DMS Panels for Remote Control

For operation of a ship’s Propulsion Line, the DMS is connected with DMS operator panels on

all control locations, including instruments for RPM and Start air pressure indication and a

pushbutton for Emergency stop:

· one in the Engine Control Room (ECR)

· one on the Bridge

· two panels on the Bridge starboard and Port Wings (optional)

· a fifth panel can be mounted on an Aft Bridge (optional)

The DMS Panel is mounted together with a Setpoint Lever on all Control Locations with DMS

Control, i.e. normally Bridge and ECR, and optionally on the Bridge Wings.

Diesel Manoeuvring System, DMS2100i Page 12 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

2.1.1 DMS Panel Functions

The following main functions are available on each control location for the Main Engine/Propulsion Line:

Analog instruments for indication of ME RPM

Analog instruments for indication of ME Start Air pressure

Dimmer potentiometer for illumination of the analog instruments (Bridge only)

Emergency stop push-button with cover

DMS2100i Operator Panel with the following functions:

ME: <Runstat> 100.0 RPM, StAir 30.00

BAR

LIMITER:<Indic1>

TLG BC: ±120.0 ECR: ±120.0 EGS: 20.0

RPM

<Oldest unacknowledged alarm/Alarm

stat>

Four lines display with 40 characters on each line

Softkeys [ S1 ] - [ S4 ] for operation of DMS functions

Six selection keys: [ ESC ], [ ENT ]

and four [ Arrow ] keys

[ Select ] of DMS control functions of

[ Status ], [ Control ] and [ Settings ]

Diesel Manoeuvring System, DMS2100i Page 13 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

Control location selection and indication for:

[ Bridge Ctrl. ] key for indication and Request / Acknowledge of Automatic

Bridge.

References: Chapter 3.1.

[ E.C.R. Control ] key for indication and Request / Acknowledge of ECR

Control Station (Automatic ECR or Manual ECR Control).

References: Chapter 3.1.

[ Local Ctrl. ] key for indication and Request / Acknowledge of Local (Emergency) Control Station. (Manual LOP Control)

References: Chapter 3.1.

SUB-Telegraph selection and indication for:

[ Sea Mode ] operation and indication key:

Activation of this key commands Sea Mode and alarm for this is released.

Mode conditions: Control air on, Safety air on, Main start valve not blocked,

Starting air distributor not blocked and Turning gear not engaged.

When unacknowledged or conditions not fulfilled, the green LED is flashing.

When Sea Mode is present, the green LED is ON.

References: Chapter 3.2.3

[ Stand By ] operation and indication key:

Activation of this key commands Stand By at the Main Engine and alarm for

this is released.

Mode conditions: Control air on, Safety air on, Main start valve not blocked,

Starting air distributor not blocked and Turning gear not engaged.

When unacknowledged or conditions not fulfilled, the green LED is flashing.

When Stand By is present, the green LED is ON.

References: Chapter 3.2.2

[ F.W.E. ] operation and indication key:

Activation of this key commands Finished With Engine and alarm for this is

released.

Mode conditions: Control air pressure off, Safety air pressure off

and Main start valve blocked.

When unacknowledged or conditions not fulfilled, the green LED is flashing.

When Finished With Engine is present, the green LED is ON.

References: Chapter 3.2.1

Diesel Manoeuvring System, DMS2100i Page 14 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

Slowdown operation and indication for:

[ Slow Down ] operation and indication key:

Activation of the key invokes the Slowdown status list at the LCD display.

When Slowdown is active, the red LED is ON.

References: Chapter 3.5.

[ Slowd. Cancel ] operation and indication key:

Slowdown may be cancelled, when in Automatic Bridge or Automatic ECR

control

When in Manual ECR Control, operation takes place from the DMS as well.

When Slowdown prewarning is present, the red LED is flashing.

When the Slowdown situation is cancelled, the red LED is ON.

References: Chapter 3.5.

[ Slowd. Reset ] operation and indication key:

Slowdown may be reset, when in Automatic Bridge or Automatic ECR control and the slowdown condition is neither present nor cancelled.

When in Manual ECR Control, operation takes place from the DMS as well.

When Slowdown may be reset due to Slowdown condition back to normal or

cancelled the red LED is flashing.

References: Chapter 3.5.

Shutdown operation and indication for:

[ Shut Down ] operation and indication key:

Activation of the key invokes the Shutdown status list at the LCD display.

When Shutdown is active, the red LED is ON.

References: Chapter 3.4 and DPS2100 User Manual

[ Shutd. Cancel ] operation and indication key:

Shutdown may be cancelled, when in Automatic Bridge or Automatic ECR

control.

When not in Automatic DMS Control, operation takes place from the

DPS2100 Operator Panel in ECR, or from the LOP.

When Shutdown prewarning is present, the red LED is flashing.

When the Shutdown situation is cancelled, the red LED is ON.

References: Chapter 3.4 and DPS2100 User Manual

The [ RESET ] and [ CANCEL ] keys for Shutdown and Slow Down keys are only working on

the DMS Operator Panels which are in control, i.e. on anyone of the Bridge Operator Panels in

Bridge Control and on the ECR Operator Panel in Automatic ECR Control, however the Slowdown Reset can be configured to always require reset from the E.C.R. Operator Pane

Diesel Manoeuvring System, DMS2100i Page 15 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

Startblock and Limits Cancel operation and indication for:

[ Start Block ] operation and indication key:

Activation of the key invokes the Startblocking status list at the LCD display.

When Startblocking is present, the red LED is ON.

[ Limits Cancel ] operation and indication key:

Activation of this key Cancels the RPM Max Limit and Load program of the

DMS2100i as well as raising the Index Limiters in the ME-Engine ECS

System.

When Cancellation is present, the red LED is ON.

The [ Limits Cancel ] key is only working on the DMS Operator Panels,

which are in control, i.e. on anyone of the Bridge Operator Panels in Bridge

Control and on the ECR Operator Panel in Automatic ECR Control.

DMS2100i keys for alarm functions:

[ Stop Horn ] operation key:

Activation of this key stops the buzzer in the DMS Operator Panel.

[ Alarm Acknowledge ] operation key:

Activation of this key acknowledges the alarms present at the LCD display of

the DMS Operator Panel.

The [ Stop Horn ] and [ Alarm Ackn. ] keys can be configured to work on several different

conditions:

1. Both keys are always working in the ECR, e.g. when the Chief Engineer always wants to

be able to acknowledge alarms. Buzzer and [ Stop Horn ] are working on anyone of the

Bridge Operator Panels for all alarms announced on the bridge (configurable), but

[ Alarm Ackn. ] will not be possible on the Bridge.

2. Both keys are working on the present DMS Control Location, i.e. working on anyone of

the Bridge Operator Panels in Bridge Control and on the ECR Operator Panel in ECR

Control.

In connection with an integrated UMS alarm system, where the Watch Station can be changed to

the Bridge, the function of both keys is following the UMS Watch Station.

Diesel Manoeuvring System, DMS2100i Page 16 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

[ Alarm List ] operation and indication key:

References: Chapter 5.3.

[ Additional List ] operation and indication key:

References: Chapter 5.4.

[Display Channel ] operation and indication key:

References: Chapter 5.5.

[ Adjust Channel ] operation and indication key:

References: Chapter 5.6.

[ Maintenance ] operation and indication key:

References: Chapter 5.7.

[ Dimmer ] operation and indication key:

References: Chapter 5.8.

[ Alarm ] indication lamp for DMS2100i Alarm detected.

Any DMS2100i alarm in chapter 6 activates this indication.

[ Fault ] indication lamp for DMS2100i Operator Panel in Faulty condition,

e.g. missing communication to the Gamma Micro CPU or missing EPROM

inside the panel.

Please refer to chapter 5 and the UMS2100 System Description for further information about the

alarm system functions.

Diesel Manoeuvring System, DMS2100i Page 17 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

2.2 Manual ECR Control Equipment

All indications and operations, such as Aux. Blowers control and indication of Main Start

Valve position etc. in the ECR Control Console which used to take place on the ECR Sub Panel

are now included in the MBD supplied Main Operator Panel (MOP), please refer to the MBD

instruction manual.

Beside that the following facilities are available:

1. EMERGENCY STOP, i.e. when Emergency Stop is ordered from this pushbutton, then the

red lamp indication is ON. The pushbutton is protected with a plastic cover against unwanted operation. The pushbutton is connected to the Safety System.

2. TAKE CONTROL, i.e. when this pushbutton is activated, the ME-Engine ECS Control System makes a forced Control Transfer to Manual ECR Control. This button overrides all

other Control Transfer functions except the similar Take Control pushbutton on the LOP.

The pushbutton is connected directly to the ME-Engine ECS System.

3. INCREASE LIMITS, i.e. i.e. when this pushbutton is activated in Manual ECR Control, the

ME-Engine ECS will raise the limiters in the Governor System. The pushbutton is connected directly to the ME-Engine ECS System.

4. For Manual ECR Control the ECR Telegraph supplied with the Bridge Manoeuvring System

is equipped with:

· Two 4 – 20mA set points connected directly to the ME-Engine ECS System

· Two Stop Switches connected directly to the ME-Engine ECS System

Diesel Manoeuvring System, DMS2100i Page 18 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

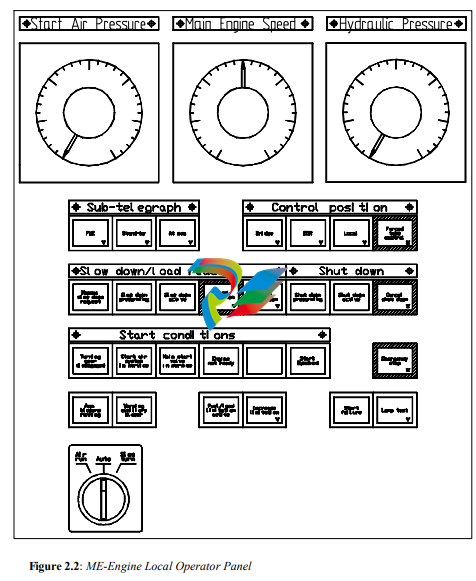

2.3 Local Operator Panel Functions

The ME-Engine Local Operator Panel (LOP), mounted locally at the ME-Engine is used for

fully electronic control from the Emergency Control Stand.

Diesel Manoeuvring System, DMS2100i Page 19 of 112

User Manual for MAN B&W ME/ME-C Engines 2004.11.02

810.000.705-01 Lyngsø Marine A/S

SAM Electronics GmbH

The ME-Engine start/stop and setpoint signals are operated from the Emergency Telegraph receiver mounted close to the LOP, with signals similar to the ECR Telegraph receiver:

· Two 4 – 20mA set points connected directly to the ME-Engine ECS System

· Two Stop Switches connected directly to the ME-Engine ECS System

The DMS2100i do however control the Sub-telegraph, the normal Control Transfer and the

Slowdown indications, and the DPS2100 Safety System control the Shutdown indications, but

the ECS will still be able to control the ME-Engine, even in case of the DMS not functioning.

The following main functions are available on the ME-Engine Local Operator Panel:

· Analog instruments for indication of: Hydraulic Pressure

· Analog instruments for indication of: ME RPM

· Analog instruments for indication of: Starting Air Pressure

· DMS Subtelegraph [Finished With Engine], [Standby] and [At Sea] selection and indication

· DMS Control transfer [Bridge], [ECR] and [Local] control selection and indication

· [Forced take Control] selection and indication

· [Manual Slowdown Request] indication

· DMS [Slow Prewarning] and [Slow Down Active] indication, [Cancel Slow Down] and

[Reset Slow Down] operation and indication

· [Shutdown Prewarning] and [Shutdown] indication, [Cancel Shutdown] operation and

indication

· Start Conditions [Turning Gear Disengaged], [Start Air Distributor in Service], [Main

Start Valve in service], [Engine not ready] and [Start Blocked] indications

· DPS [Emergency stop] activation and indication

· [Aux Blowers running] and [Aux. Blowers Warning] indication

· [Fuel/Load Limitation Active] indication and [Increase Limitation] activation and indication

· [Start Failure] indication

· [Lamp Test] pushbutton

· [Air Run], [Slowturn] and [Auto] switch

· Shutdown Reset is done by putting the LOP Telegraph in stop position. The ME-Engine ECS

system will activate the reset signal to the Safety system by means of the LOP Telegraph setpoint and Stop switch.

.png)

.png)

.png)