ABB MEASUREMENT & ANALY TICS | DATA SHEET 266DSH Differential pressure transmitters

Measurement made easy

Engineered solutions for all applications

Base accuracy

• from 0.06 % of calibrated span (optional 0.04 %)

Reliable sensing system coupled with very latest digital technologies

• provides large turn down ratio up to 100:1

Comprehensive sensor choice

• optimize in-use total performance and stability

10–year stability

• 0.15 % of URL

Flexible configuration facilities

• provided locally via local LCD keypad

TTG (Through-The-Glass) keypad technology

• allows quick and easy local configuration without opening the cover,

even in explosion proof environments

IEC 61508 certification

• version for SIL2 (1oo1) and SIL3 (1oo2) applications

PED compliance

• Category III for PS > 20 MPa, 200 bar

• Sound Engineering Practice (SEP) for PS ≤ 20 MPa, 200 bar

WirelessHART version

• the battery powered solution compliant to IEC 62591

Best-in-class battery life

• up to 10 years @ 32 s update time

• in-field replaceable

Product in compliance with Directive 2011/65/UE (RoHS II)

In-built advanced diagnostics

Specification – functional

Range and span limits

Sensor

code

Upper range limit

(URL)

Lower range limit

(LRL)

Minimum

measuring span

A 1 kPa

10 mbar

4 inH2O

–1 kPa

–10 mbar

–4 inH2O

0.05 kPa

0.5 mbar

0.2 inH2O

B 4 kPa

40 mbar

16 inH2O

–4 kPa

–40 mbar

–16 inH2O

0.2 kPa

2 mbar

0.8 inH2O

E 16 kPa

160 mbar

64 inH2O

–16 kPa

–160 mbar

–64 inH2O

0.54 kPa

5.4 mbar

2.16 inH2O

F 40 kPa

400 mbar

160 inH2O

–40 kPa

–400 mbar

–160 inH2O

0.4 kPa

4 mbar

1.6 inH2O

H* 160 kPa

1600 mbar

642 inH2O

–160 kPa

–1600 mbar

–642 inH2O

1.6 kPa

16 mbar

6.4 inH2O

M* 600 kPa

6 bar

87 psi

–600 kPa

–6 bar

–87 psi

6 kPa

0.06 bar

0.87 psi

P* 2400 kPa

24 bar

348 psi

–2400 kPa

–24 bar

–348 psi

24 kPa

0.24 bar

3.5 psi

Q* 8000 kPa

80 bar

1160 psi

–8000 kPa

–80 bar

–1160 psi

80 kPa

0.8 bar

11.6 psi

S* 16000 kPa

160 bar

2320 psi

–16000 kPa

–160 bar

–2320 psi

160 kPa

1.6 bar

23.2 psi

* For 266DSH gauge version the LRL for sensors H, M, P, Q, S is 1 kPa abs /

10 mbar abs / 0.15 psia

Span limit

Maximum span = URL

(can be further adjusted up to ± URL (TD = 0.5) for

differential models, within the range limits)

IT IS RECOMMENDED TO SELECT THE TRANSMITTER

SENSOR CODE PROVIDING THE TURNDOWN VALUE AS

LOWEST AS POSSIBLE TO OPTIMIZE PERFORMANCE

CHARACTERISTICS.

Zero suppression and elevation

Zero and span can be adjusted to any value within the

range limits detailed in the table as long as:

– calibrated span ≥ minimum span

Damping (feature not available for WirelessHART version)

Selectable time constant : between 0 and 60 s

This is in addition to sensor response time.

Turn on time

Operation within specification in less than 10 s with

minimum damping.

Insulation resistance

> 100 MΩ at 500 V DC (terminals to earth)

Specification – operative limits

Pressure limits

Overpressure limits

The differential pressure transmitters, models 266DSH,

work without damage within the following pressure limits:

Sensors Fill fluid Overpressure limits

Sensor F to S Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 21 MPa, 210 bar, 3045 psi *, **

Sensor E Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 16 MPa, 160 bar, 2320 psi *

Sensor B Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 7 MPa, 70 bar, 1015 psi *

Sensor A Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 2 MPa, 20 bar, 290 psi *

Sensor F to S Inert

(Galden)

0.135 kPa abs, 1.35 mbar abs, 1 mmHg

and 21 MPa, 210 bar, 3045 psi *, **

Sensor E Inert

(Galden)

0.135 kPa abs, 1.35 mbar abs, 1 mmHg

and 16 MPa, 160 bar, 2320 psi *

* 1 MPa, 10 bar, 145 psi for Kynar-PVDF

** 16 MPa, 160 bar, 2320 psi for AISI 316 ss NACE “exposed bolting“

For flange mounted version

Flange Fill fluid Overpressure limits

ASME B16.5

Class 150

Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 230 psi

ASME B16.5

Class 300

Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 600 psi

EN 1092-1 PN 16 Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 13.5 bar

EN 1092-1 PN 40 Silicone oil 0.07 kPa abs, 0.7 mbar abs, 0.5 mmHg

and 33.8 bar

ASME B16.5

Class 150

Inert

(Galden)

0.135 kPa abs, 1.35 mbar abs, 1 mmHg

and 230 psi

ASME B16.5

Class 300

Inert

(Galden)

0.135 kPa abs, 1.35 mbar abs, 1 mmHg

and 600 psi

EN 1092-1 PN 16 Inert

(Galden)

0.135 kPa abs, 1.35 mbar abs, 1 mmHg

and 13.5 bar

EN 1092-1 PN 40 Inert

(Galden)

0.135 kPa abs, 1.35 mbar abs, 1 mmHg

and 33.8 bar

Static pressure limits

The differential pressure transmitters, models 266DSH

work within specifications between the following limits:

Sensors Static pressure limits

Sensor F to S 1.3 kPa abs, 13 mbar abs, 0.2 psia

and 21 MPa, 210 bar, 3045 psi *, **

Sensor E 1.3 kPa abs, 13 mbar abs, 0.2 psia

and 16 MPa, 160 bar, 2320 psi *

Sensor B 1.3 kPa abs, 13 mbar abs, 0.2 psia

and 7 MPa, 70 bar, 1015 psi *

Sensor A 1.3 kPa abs, 13 mbar abs, 0.2 psia

and 2 MPa, 20 bar, 290 psi *

* 1 MPa, 10 bar, 145 psi for Kynar-PVDF

** 16 MPa, 160 bar, 2320 psi for AISI 316 ss NACE “exposed bolting“

Flange Static pressure limits

ASME B16.5 Class 150 1.3 kPa abs, 13 mbar abs, 0.2 psia and 230 psi

ASME B16.5 Class 300 1.3 kPa abs, 13 mbar abs, 0.2 psia and 600 psi

EN 1092-1 PN 16 1.3 kPa abs, 13 mbar abs, 0.2 psia and 13.5 bar

EN 1092-1 PN 40 1.3 kPa abs, 13 mbar abs, 0.2 psia and 33.8 bar

The pressure limit decreases with increasing temperature above 100°F

(38°C), according to ASME B16.5 standards or above 50°C according to

EN 1092-1 standards.

Proof pressure

The transmitter with threaded process connection can be

exposed without leaking to line pressure of up to

• 48 MPa, 480 bar, 6960 psi for standard static version

• up to two times the flange rating for the flange

mounted version.

Meet ANSI/ISA-S 82.03 hydrostatic test requirements.

Temperature limits °C ( °F)

Ambient

is the operating temperature

Models 266DSH Ambient temperature limits

Silicone oil for sensor F to S –40 and 85 °C (–40 and 185 °F)

Silicone oil for sensor A to E –40 and 85 °C (–40 and 185 °F)*

Inert (Galden) for sensor F to S –20 and 85 °C (–4 and 185 °F)

Inert (Galden) for sensor E –10 and 85 °C (14 and 185 °F)

Models 266DSH Ambient temperature limits

LCD integral display –40 and 85 °C (–40 and 185 °F)

LCD display may be affected in visibility below -20°C (-4°F) or above +70°C

(+185°F).

Transmitters with ambient temperature limit of -50°C (-58° F) are available

through special option.

This special option is not compatible with communication protocol option

“7”

IMPORTANT

For Hazardous Atmosphere applications see the

temperature range specified on the certificate/approval

relevant to the aimed type of protection

Process

Models 266DSH Process temperature limits

Silicone oil for sensor F to S –40 and 121 °C (–40 and 250 °F) *

Silicone oil for sensor A to E –25 and 121 °C (–13 and 250 °F) *

Inert (Galden) for sensor F to S –20 and 100 °C (–4 and 212 °F) **

Inert (Galden) for sensor E –10 and 100 °C (14 and 212 °F) **

* 100 °C (212 °F) for application below atmospheric pressure

** 65 °C (150 °F) for application below atmospheric pressure

Models 266DSH Process temperature limits

Viton gasket –20 and 121 °C (–4 and 250 °F)

Storage

Models 266DSH Storage temperature limits

Storage limits –50 and 85 °C (–58 and 185 °F)

LCD integral display –40 and 85 °C (–40 and 185 °F)

* between -40°C (-40° F) and -25°C (-13° F) device response

time might be influenced

Environmental limits

Electromagnetic compatibility (EMC)

Comply with 2014/30/UE to standards EN 61326-1:2013.

For IEC 61508 SIL certified transmitter to

EN 61326-3-1:2008.

For transmitter with option “YE” to NAMUR NE 021 (2004).

Surge immunity level (with surge protector): 4 kV

(according to IEC 61000-4–5 EN 61000–4–5)

Pressure equipment directive (PED)

Comply with 2014/68/UE to standards

ANSI/ISA 61010-1:2012

Category III Module H for PS ≥ than 20 MPa, 200 bar

Sound Engineering Practice (SEP) for PS < 20 MPa, 200 bar

Humidity

Relative humidity: up to 100 %

Condensing, icing: admissible

Vibration resistance

Accelerations up to 2 g at frequency up to 1000 Hz

(according to IEC 60068–2–6)

Shock resistance

Acceleration: 50 g

Duration: 11 ms

(according to IEC 60068–2–27)

Wet and dust-laden atmospheres

The transmitter is dust and sand tight and protected

against immersion effects as defined by IEC 60529 (2001)

to IP 67 (IP 68 on request) or by NEMA Type 4X.

IP65 with Harting Han connector.

Aluminium and AISI housings as barrel version also comply

to IP 66 as defined by IEC 60529 (2001).

IP66W/IP67W/IP68W as standard for Inmetro certification.

...Specification – operative limits

Hazardous atmospheres

(FOR ALL VERSIONS EXCEPT WirelessHART)

With or without integral display

INTRINSIC SAFETY Ex ia:

• ATEX Europe (code E1) approval

II 1 G Ex ia IIC T6...T4 Ga, II 1/2 G Ex ia IIC T6...T4 Ga/Gb,

II 1 D Ex ia IIIC T85 °C Da, II 1/2 D Ex ia IIIC T85 °C Da;

IP66, IP67.

• IECEx (code E8) approval

Ex ia IIC T6...T4 Ga/Gb, Ex ia IIIC T85 °C Da; IP66, IP67.

• NEPSI China (code EY)

Ex ia IIC T4/T5/T6 Ga, Ex ia IIC T4/T5/T6 Ga/Gb,

Ex iaD 20 T85/T100/T135, Ex iaD 20/21 T85/T100/T135.

EXPLOSION PROOF:

• ATEX Europe (code E2) approval

II 1/2 G Ex db IIC T6 Ga/Gb Ta=–50 °C to +75 °C,

II 1/2 D Ex tb IIIC T85 °C Db Ta = –50 °C to +75 °C;

IP66, IP67.

• IECEx (code E9) approval

Ex db IIC T6 Ga/Gb Ta=–50 °C to +75 °C,

Ex tb IIIC T85 °C Db Ta = –50 °C to +75 °C; IP66, IP67.

• NEPSI China (code EZ)

Ex d IIC T6 Gb, Ex tD A21 IP67 T85 °C.

INTRINSIC SAFETY Ex ic:

• ATEX Europe (code E3 ) type examination

II 3 G Ex ic IIC T6...T4 Gc,

II 3 D Ex tc IIIC T85 °C Dc; IP66, IP67.

• IECEx (code ER) type examination

Ex ic IIC T6...T4 Gc, Ex tc IIIC T85 °C Dc; IP66, IP67.

• NEPSI China (code ES) type examination

Ex ic IIC T4~T6 Gc, Ex nA IIC T4~T6 Gc,

Ex tD A22 IP67 T85 °C.

FM Approvals US (code E6) and

FM Approvals Canada (code E4):

• Explosionproof (US): Class I, Division 1,

Groups A, B, C, D; T5

• Explosionproof (Canada): Class I, Division 1,

Groups B, C, D; T5

• Dust-ignitionproof: Class II, Division 1, Groups E, F, G;

Class III, Div. 1; T5

• Flameproof (US): Class I, Zone 1 AEx d IIC T4 Gb

• Flameproof (Canada): Class I, Zone 1 Ex d IIC T4 Gb

• Nonincendive: Class I, Division 2, Groups A, B, C, D T6...T4

• Energy limited (US): Class I, Zone 2 AEx nC IIC T6...T4

• Energy limited (Canada): Class I, Zone 2 Ex nC IIC T6...T4

• Intrinsically safe:Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G T6...T4

Class I, Zone 0 AEx ia IIC T6...T4 (US)

Class I, Zone 0 Ex ia IIC T6...T4 (Canada)

Type 4X, IP66, IP67 for all above markings.

COMBINED FM Approvals US and Canada

• Intrinsically safe (code EA)

COMBINED ATEX, FM and IECEx Approvals (code EN)

Technical Regulations Customs Union EAC (Russia,

Kazakhstan, Belarus), Inmetro (Brazil), Kosha (Korea)

(ONLY FOR WirelessHART VERSION)

With or without integral display

INTRINSIC SAFETY Ex ia:

• ATEX Europe (code E1) approval

II 1 G Ex ia IIC T4 and II 1/2 G Ex ia IIC T4, IP67.

• IECEx (code E8) approval

Ex ia IIC T4

FM Approvals US and FM Approvals Canada:

• Intrinsically safe:Class I, Division 1, Groups A, B, C, D; T4

Class I, Zone 0 AEx ia IIC T4 Gb (US)

Class I, Zone 0 Ex ia IIC T4 Gb (Canada)

IP67 for all above markings.

IMPORTANT

REFER TO CERTIFICATES FOR AMBIENT TEMPERATURE

RANGES RELATED TO THE DIFFERENT TEMPERATURE

CLASSES.

Electrical Characteristics and Options

Optional indicators

Integrated digital display

(code LS; only with HART standard functionality)

Wide screen LCD, 128 x 64 pixel,

52.5 x 27.2 mm (2.06 x 1.07 in.) dot matrix.

Two keys for zero/span or without front

push buttons when ordered with R1

external pushbuttons option

Display may also indicate static pressure,

sensor temperature and diagnostic messages.

Integral display with integral keypad

(code L1; not with HART standard functionality)

Wide screen LCD, 128 x 64 pixel,

52.5 x 27.2 mm (2.06 x 1.07 in.) dot matrix.

Multilanguage. Four keys for configuration

and management of device.

Easy setup for quick commissioning.

User selectable application-specific

visualizations.

Totalized and instantaneous flow indication.

Display may also indicate static pressure, sensor

temperature and diagnostic messages and provides

configuration facilities.

Integral display with Through-The-Glass (TTG) activated

keypad (code L5; not with HART standard functionality)

As above integral display but equipped

with the innovative TTG keypad allowing

the activation of the configuration and

management menus of the device without

the need of removing the transmitter

housing cover. TTG keypad is protected

against accidental activations.

Optional surge protection

Up to 4kV

• voltage 1.2 µs rise time / 50 µs delay time to half value

• current 8 µs rise time / 20 µs delay time to half value

Process diagnostics (PILD)

Plugged impulse line detection (PILD) generates a warning

via communication (HART, PA, FF). The device can be

configured to drive the output to “Alarm current” or set a

status “BAD”.

HART®

digital communication and 4 to 20 mA

output – Standard and Advanced functionality

Device type: 1a06hex (listed with HCF)

Power supply

The transmitter operates from 10.5 to 42 V DC with no

load and is protected against reverse polarity connection

(additional load allows operations over 42 V DC).

For Ex ia and other intrinsically safe approval power

supply must not exceed 30 V DC. Minimum operating

voltage increases to 12.3 V DC with optional surge

protector or to 10.8 V DC with optional conformity to

NAMUR NE 21 (2004).

Ripple

20 mV max on a 250 Ω load as per HART specifications.

Load limitations

4 to 20 mA and HART total loop resistance :

A minimum of 250 Ω is required for HART communication.

Output signal

Two–wire 4 to 20 mA, user-selectable for linear or square

root output, power of 3

/2 or 5

/2 , square root for

bidirectional flow, 22 points linearization table (i.e. for

horizontal or spherical tank level measurement). HART®

communication provides digital process variable

superimposed on 4 to 20 mA signal, with protocol based

on Bell 202 FSK standard.

HART revision 7 is the default HART output.

HART revision 5 is selectable on request.

Output current limits (to NAMUR NE 43 standard)

Overload condition

• Lower limit: 3.8 mA (configurable from 3.8 to 4 mA)

• Upper limit: 20.5 mA (configurable from 20 to 21 mA)

Alarm current

• Lower limit: 3.6 mA (configurable from 3.6 to 4 mA)

• Upper limit: 21 mA (configurable from 20 to 23 mA,

limited to 22 mA for HART Safety; apply for electronics

release 7.1.15 or later)

Factory setting: high alarm current.

...Specification – electrical characteristics and options

IEC 62591 WirelessHART®

output

Device type: 1a06hex (listed with HCF)

Network ID: ABBhex (2747 decimal)

Join keys: 57495245hex (1464422981) 4c455353hex (1279611731)

4649454chex (1179206988) 444b4559hex (1145783641).

Power Supply

1x D-cell size lithium-thionyl chloride battery.

Battery life: 10 years at 32 sec. update time, 8 years at 16

sec. update time or 5 years at 8 sec. update time.

(at reference conditions of 25 ± 2 °C ambient temperature,

data routed from 3 additional devices, LCD off).

THE BATTERY CAN BE REPLACED IN FIELD, ALSO IN

HAZARDOUS CLASSIFIED AREA.

Output signal

IEC 62591 WirelessHART Version 7.5 (IEEE 802.15.4-2006);

Frequency band: 2.4 GHz DSSS

Update rate: user selectable from 1 sec. to 60 min.

Integrated adjustable omnidirectional antenna

– Output radio frequency: maximum 10 mW (10 dBm) EIRP

– Range: up to 300 m. (328 yds.)

Minimum distance between antenna and person is 0.2 m.

(8 in.)

Telecommunications directive

Every wireless measuring device must be certified in

accordance with the telecommunications directive, in this

case the frequency range. This certification is countryspecific.

European directives

Radio Equipment & Telecommunications Terminal

Equipment Directive 2014/53/UE to standards EN 60950-

1:2013,

EN 62311:2008, EN 301 489-1 V1.9.2, EN 301 489-17 V2.2.1,

EN 300 328 v1.8.1.

In Europe, use of the 2400 - 2483.5 MHz frequency band is

not harmonized. Country-specific regulations must be

observed.

Restrictions for Norway

Operation not permitted within a radius of 20 km around

Ny-Alesund in Svalbard. For more information, see

www.npt.no Norway Posts and Telecommunications site

Extra-european radio frequency licences

USA to FCC Part 15.247:2009;

Canada to IC RSS-210 and ICES-003;

Argentina; United Arab Emirates (UAE); India; Mexico.

PROFIBUS®

PA output

Device type

Pressure transmitter compliant to Profiles 3.0.1

Identification number: 3450 (hex)

Power supply

The transmitter operates from 9 to 32 V DC , polarity

independent, with or without surge protector.

For Ex ia approval power supply must not exceed 17.5 V DC.

Intrinsic safety installation according to FISCO model.

Current consumption

operating (quiescent): 15 mA

fault current limiting: 20 mA max.

Output signal

Physical layer in compliance to IEC 1158–2/EN 61158–2

with transmission to Manchester II modulation, at 31.25

kbit/s.

Output interface

PROFIBUS PA communication according to Profibus

DP50170 Part 2/DIN 19245 part 1–3.

Output update time

25 ms

Data blocks

3 analog input, 1 physical.

Additional blocks

1 Pressure with calibration transducer block

1 Advanced Diagnostics transducer block including

Plugged Input Line Detection

1 Local Display transducer block

Transmitter failure mode

On gross transmitter failure condition, detected by selfdiagnostics, the output signal can be driven to defined

conditions, selectable by the user as safe, last valid or

calculated value.

If electronic failure or short circuit occur the transmitter

consumption is electronically limited at a defined value

(20 mA approx), for safety of the network.

FOUNDATION FieldbusTM output

Device type

LINK MASTER DEVICE

Link Active Scheduler (LAS) capability implemented.

Manufacturer code: 000320hex

Device type code: 0007hex

Power supply

The transmitter operates from 9 to 32 V DC, polarity

independent, with or without surge protector.

For Ex ia approval power supply must not exceed 24 V DC

(FF–816 certification) or 17.5 V DC (FISCO certification).

Current consumption

operating (quiescent): 15 mA

fault current limiting: 20 mA max.

Output signal

Physical layer in compliance to IEC 61158–2/EN 61158–2.

Transmission to Manchester II modulation, at 31.25 kbit/s.

Function blocks/execution period

3 enhanced Analog Input blocks/25 ms max (each)

1 enhanced PID block/40 ms max.

1 standard ARitmetic block/25 ms

1 standard Input Selector block/25 ms

1 standard Control Selector block/25 ms

1 standard Signal Characterization block/25 ms

1 standard Integrator/Totalizer block/25 ms

Additional blocks

1 enhanced Resource block,

1 custom Pressure with calibration transducer block

1 custom Advanced Diagnostics transducer block

including Plugged Input Line Detection

1 custom Local Display transducer block

Number of link objects

35

Number of VCRs

35

Output interface

FOUNDATION fieldbus digital communication protocol to

standard H1, compliant to specification V. 1.7.

Transmitter failure mode

The output signal is “frozen” to the last valid value on

gross transmitter failure condition, detected by selfdiagnostics which also indicate a BAD conditions. If

electronic failure or short circuit occur the transmitter

consumption is electronically limited at a defined value

(20 mA approx), for safety of the network.

Specification – performance

Stated at reference condition to IEC 60770 ambient

temperature of 20 °C (68 °F), relative humidity of 65 %,

atmospheric pressure of 1013 hPa (1013 mbar), mounting

position with vertical diaphragm and zero based range for

transmitter with isolating diaphragms in AISI 316 L ss or

Hastelloy and silicone oil fill and HART digital trim values

equal to 4 mA and to 20 mA span end points, in linear

mode.

Unless otherwise specified, errors are quoted as % of

span.

Some performance referring to the Upper Range Limit are

affected by the actual turndown (TD) as ratio between

Upper Range Limit (URL) and calibrated span.

IT IS RECOMMENDED TO SELECT THE TRANSMITTER

SENSOR CODE PROVIDING THE TURNDOWN VALUE AS

LOWEST AS POSSIBLE TO OPTIMIZE PERFORMANCE

CHARACTERISTICS.

Dynamic performance (according to IEC 61298–1

definition)

Sensors Total response time

Sensor M to S ≤ 100 ms

Sensor F to H ≤ 100 ms*

Total response time for sensor E ≤ 130 ms*, for sensor B ≤ 310 ms*

Total response time includes dead time of 30 ms (for all sensors) with

time constant @ 63.2 % of total step change.

See “Update Rate” for WirelessHART version.

Accuracy rating (Elin)

% of calibrated span, including combined effects of

terminal based linearity, hysteresis and repeatability.

For fieldbus versions SPAN refer to analog input function

block outscale range

Model Sensor for TD

266DSH F to P from 1:1 to 10:1 ± 0.06 %

F to P from 10:1 to 100:1 ± (0.006 x TD) %

E, Q, S from 1:1 to 10:1 ± 0.075 %

Q and S from 10:1 to 100:1 ± (0.0075 x TD) %

E from 10:1 to 30:1 ± (0.0075 x TD) %

B from 1:1 to 10:1 ± 0.10 %

B from 10:1 to 20:1 ± (0.01 x TD) %

A from 1:1 to 4:1 ± 0.10 %

A from 4:1 to 20:1 ± (0.025 x TD) %

266DSH

(option D2)

F to Q from 1:1 to 5:1 ± 0.04 %

F to P from 5:1 to 100:1 ± (0.0105 + 0.0059 x TD) %

Q from 5:1 to 100:1 ± (0.003 + 0.0074 x TD) %

(*) Availability subject to special request and not applicable

for explosionproof and flameproof

Ambient temperature (E∆Tz + E∆Ts)

per 20K change between the limits of –40 °C to +85 °C

(per 36 °F change between the limits of –40 to +185 °F):

Model Sensor for TD up to

266DSH F to Q 10:1 ± (0.03 % URL + 0.045 % span)

E and S 10:1 ± (0.04 % URL + 0.065 % span)

B 10:1 ± (0.06 % URL + 0.10 % span)

A 4:1 ± (0.10 % URL + 0.10 % span)

for an ambient temperature change from –10 °C to +60 °C

(+14 to +140 °F):

Model Sensor for TD up to

266DSH F to Q 10:1 ± (0.055 % URL + 0.08 % span)

E and S 10:1 ± (0.075 % URL + 0.11 % span)

B 10:1 ± (0.11 % URL + 0.18 % span)

A 4:1 ± (0.18 % URL + 0.18 % span)

per 10K change between the limits of –40 °C to –10 °C or

+60° to +85 °C (per 18 °F change between the limits of –40

to +14 °F or +140° to +185 °F):

Model Sensor for TD up to

266DSH F to Q 10:1 ± (0.03 % URL + 0.04 % span)

E and S 10:1 ± (0.04 % URL + 0.055 % span)

B 10:1 ± (0.055 % URL + 0.09 % span)

A 4:1 ± (0.09 % URL + 0.09 % span)

Static pressure (E∆Ps)

(zero errors can be calibrated out at line pressure)

per 0.5 MPa, 5 bar or 72.5 psi (sensor A)

per 2 MPa, 20 bar or 290 psi (sensor B)

per 3.5 MPa, 35 bar or 500 psi (sensor E)

per 7 MPa, 70 bar or 1015 psi (sensor F to S)

Model 266DSH standard static

• zero error: ±0.05 % of URL for sensor F to S

±0.08 % of URL for sensor A, B and E

• span error: ±0.08 % of reading.

Model 266DSH flange mounted

per 2 MPa, 20 bar or 290 psi

• zero error: ±0.05 % of URL for sensor F to P

±0.08 % of URL for sensor E

span error: ±0.08 % of reading.

Supply voltage

Within voltage/load specified limits the total effect is less

than 0.005 % of URL per volt.

Load

Within load/voltage specified limits the total effect is

negligible.

Electromagnetic field

Meets all the requirements of EN 61326 for surge

immunity level (of NAMUR NE 21 on request).

Common mode interference

No effect from 100Vrms @ 50Hz, or 50 V DC

Mounting position

Rotations in the plane of the diaphragm have a negligible

effect. A tilt from the vertical of up to 90° causes a zero

point shift of up to 0.5 kPa (5 mbar, 2 inH2O), which can be

corrected by making an appropriate zero position

adjustment. There is no effect on the measuring span.

In applications where a dynamic inclined installation is

required (e.g. naval applications with maximum vessel

inclination of +/-22.5°), the maximum error can be up to 3

mbar for 266DSH

Such error might be resulting in a deviation from the

standard accuracy with percentual magnitude depending

on the range of the selected device.

In case of non-dynamic inclined installations, this effect

can be eliminated by performing a zero calibration in the

field.

Please contact ABB to assess more in details on the

installation effects

Stability

±0.15 % of URL over a ten years period

(±0.25 % of URL over a ten years period for sensor A or B)

Maximum total performance

For temperature change of 28 °C (50 °F), static pressure

change of 5,1 MPa, 51 bar, 740 psi, for model 266DSH with

accuracy option code D2 (± 0.04 %)

Sensor Span Maximum total performance

F 35 kPa, 350 mbar, 140 inH2O ≤± 0.125 % of calibrated span

H 150 kPa, 1,5 bar, 600 inH2O

M 550 kPa, 5,5 bar, 80 psi

EMperf = √ (E∆Tz + E∆Ts)2

+ E∆Ps 2

+ Elin 2

EMperf = Maximum total performance

E∆Tz = Effect of the ambient temperature on zero

E∆Ts = Effect of the ambient temperature on span

E∆Ps = Effect of the static pressure on span

Elin = Accuracy rating (for terminal-based linearity 0.04 %)

Total performance

similar to DIN 16086

Temperature change in the range from –10 to 60 °C (14 to 140 °F),

static pressure change (266DSH) 10 MPa, 100 bar, 1450 psi

Model Sensor TD Total performance

266DSH std. static, D2 option F to Q 1:1 ≤± 0.16 % of calibrated span

Eperf = √ (E∆Tz + E∆Ts)2

+ E∆Ps 2

+ Elin 2

Eperf = Total Performance

E∆Tz = Effect of the ambient temperature on zero

E∆Ts = Effect of the ambient temperature on span

E∆Ps = Effect of the static pressure on span

Elin = Accuracy rating (for terminal-based linearity 0.04 %

or 0.075% as per model/sensor accuracy)

Maximum total performance and Total performance

includes the measuring errors of

• non-linearity including hysteresis and nonreproducibility,

• thermal change of the ambient temperature as regards

the zero signal and the calibrated span,

• effect of static pressure change on the calibrated span,

with transmitter re-zeroed at line pressure.

Specification – physical

(Refer to ordering information sheets for variant availability related to specific model or versions code)

Materials

Process isolating diaphragms (*)

AISI 316 L ss; AISI 316 L ss gold plated; Tantalum;

Hastelloy®

C-276; Hastelloy®

C-276 on AISI 316L ss gasket

seat.

Process flanges, adapters, plugs and drain/vent valves (*)

AISI 316 L ss (1); Hastelloy®

C-276 (2);

Kynar®

(PVDF insert in AISI 316 ss flange).

AISI 316 L ss with flushing connections for high side of

flange mounted version.

Sensor fill fluid

Silicone oil; Inert fill (Galden®

).

Mounting bracket (**)

Zinc plated carbon steel with chrome passivation; AISI 316

ss; AISI 316 L ss.

Gaskets (*)

Viton®

; PTFE.

Sensor housing

AISI 316 L ss.

Bolts and nuts

AISI 316 ss bolts Class A4–80 and nuts Class A4–70

per ISO 3506;

AISI 316 ss bolts and nuts Class A4–50 per ISO 3506, in

compliance with NACE MR0175 Class II (std. static only).

Plated alloy steel bolts per ASTM-A-193-77a grade B7M and

nuts per ASTM A194/A 194 M-90 grade 2HM, in compliance

with NACE MR0175 Class II.

Electronic housing and covers

Aluminium alloy (copper content ≤ 0.3 %) with baked

epoxy finish (colour RAL9002); AISI 316 L ss.

Covers O-ring

Buna N.

Local adjustments (zero, span and write protect)

For Standard HART version:

• Internal for zero and span (on connection board)

• External non-intrusive for zero, span and write protect

in glass filled polyphenylene oxyde, removable (code

R1).

For all other versions:

• External non-intrusive for zero, span and write protect

in glass filled polyphenylene oxyde, removable.

Plates

Transmitter nameplate: AISI 316 ss screwed to the

electronics housing.

Certification plate and optional tag/calibration plate: selfadhesive attached to the electronics housing or AISI 316 ss

fastened to the electronics housing with rivets or screws.

Optional wired-on customer data plate: AISI 316 ss.

Laser printing on metal or thermal printing on selfadhesive.

For AISI 316 L ss housing it is mandatory to select option

I2 or I3 for plates in AISI 316 ss.

Optional wired-on customer data plate can be populated

with customized data (4 lines of 32 characters 4 mm/0.16

in high).

Customized data have to be provided separately: in case

of no data, the wired-on plate will be delivered blank.

Calibration

Standard: at maximum span, zero based range, ambient

temperature and pressure;

Optional: at specified range and ambient conditions.

Device is delivered with a standard 4-point calibration

record

(*) Wetted parts of the transmitter.

(**)U-bolt material: high-strength alloy steel or AISI 316 L ss;

bolts/nuts material: high-strength alloy steel or AISI 316 ss.

(1) Supplied as AISI 316 L or as ASTM A351 Grade CF-3M

(2) Supplied as Hastelloy C-276 or as ASTM A494 alloy

CW-12MW

Optional extras

Mounting brackets (code Bx)

For vertical and horizontal 60mm. (2in) pipes or wall

mounting. (EXCEPT U-BOLT ASSEMBLY WHICH IS NOT

SUPPLIED FOR WALL MOUNTING, PARTS ARE THE SAME

FOR PIPE AND WALL BRACKET OPTIONS, AS PER

RELEVANT MATERIALS).

Display (code Lx)

L1/L5: 4 position (90° steps) user orientable

LS: fixed position

Optional plates (code Ix)

Code I1: AISI 316 ss wired-on plate with laser printed

customized data (4 lines of 32 characters with 4 mm/0.16

in. height).

Code I2: AISI 316 ss plate with laser printed tag (up to 32

characters - long) and calibration details (up to 32

characters: lower and upper range values and engineering

unit) fixed onto transmitter housing.

Code I3: complete set of AISI 316 ss plates (see I1 and I2).

Surge protection (code S2)

Cleaning procedure for oxygen service (code P1)

Test Certificates (test, design, calibration, material

traceability) (codes Cx and Hx)

Tag and manual language (codes Tx and Mx)

Manifold mounting (code A1)

Factory mounting and pressure test of ABB M26

manifolds.

Process connections

on flanges: 1/4 in. – 18 NPT on process axis

on adapters: 1/2 in. – 14 NPT on process axis

centre distance (266DSH): 54 mm. (2.13 in.) on flange;

51, 54 or 57 mm. (2.01, 2.13 or 2.24 in.) as per adapters

fittings

fixing threads: 7/16 in. – 20 UNF at 41.3 mm centre

distance

High pressure side of flange mounted version (*):

2 in. or 3 in., ASME Class 150 or Class 300 RF;

DN 50 or DN 80, PN 16 or PN 40 to EN 1092-1 Type B1

(*) Bolts and nuts, gasket and mating flange supplied by customer.

Electrical connections

Two 1/2 in. – 14 NPT or M20x1.5 threaded conduit entries,

direct on housing. Only M20x1.5 for WirelessHART with

one port used for antenna.

One certified stainless steel plug (supplied loose with

thread according to housing entries) available as option.

Terminal block

HART version: three terminals for signal/external meter

wiring up to 2.5 mm2

(14 AWG), also connection points for

test and communication purposes.

WirelessHART version: connection points for test and

communication purposes; additional fast connection for

external harvesting unit.

Fieldbus versions: two terminals for signal wiring (bus

connection) up to 2.5 mm2

(14 AWG)

Grounding

Internal and external 6 mm2 (10 AWG) ground termination

points are provided.

Mounting position

Transmitter can be mounted in any position.

Electronics housing may be rotated to any position. A

positive stop prevents over travel.

Mass (without options)

4 kg approx (8.8 lb) for standard static and gauge

versions;

7 to 11 kg approx (16 to 24 lb) for flange mounted version;

add 1.5 kg (3.3 lb) for AISI housing.

Add 650 g (1.5 lb) for packing.

Packing

Carton 27 x 24 x 20 cm approx (11 x 10 x 8 in.);

Carton 35 x 33 x 35 cm approx (14 x 13 x 14 in) for flange

mounted version

Specification – configuration

Transmitter with HART communication

and 4 to 20 mA

Standard configuration

Transmitters are factory calibrated to customer's

specified range. Calibrated range and tag number are

stamped on the tag plate. If a calibration range and tag

data are not specified, the transmitter will be supplied

with the plate left blank and configured as follows:

Engineering Unit kPa

4 mA Zero

20 mA Upper Range Limit (URL)

Output Linear

Damping 1 s

Transmitter failure mode Upscale

Tag Blank (up to 32 alphanumeric

characters - long;

only 8 visible on display - short)

Optional LCD display PV in kPa; output in mA and

in percentage on bargraph

Any or all the above configurable parameters, including

Lower range–value and Upper range-value which must be

the same unit of measure, can be easily changed using the

HART hand–held communicator or by a PC running the

configuration software with DTM for 266 models. The

transmitter database is customized with specified flange

type and material, O–ring and drain/vent materials and

meter code option.

Tag and Calibration

Tag and/or specific calibrated span can be requested

when configuring the device.

Two tag types are available: Short Tag and Long Tag.

See below table for details about tag type applicability /

presence:

Type Max Length On Display On CertificationOn Device Label

Short Tag 8 digits YES YES NO

Long Tag 32 digits NO YES YES

In case no specific indication will be given about the tag

type, data will be considered as Long Tag by default.

In case tag is required on the optional wired-on customer

data plate (optional digits I1, I3) specific indication needs

to be given.

Custom configuration (option N6)

The following data may be specified in addition to the

standard configuration parameters:

Descriptor 16 alphanumeric characters

Message 32 alphanumeric characters

Date Day, month, year

For HART protocol available engineering units of pressure

measure are :

Pa, kPa, MPa

inH2O@4 °C, mmH2O@4 °C, psi

inH2O@68 °F, ftH2O@68 °F, mmH2O@68 °F

inHg, mmHg, Torr

g/cm2

, kg/cm2

, atm

mbar, bar

These and others are available for PROFIBUS and

FOUNDATION Fieldbus.

Transmitter with WirelessHART

communication

Standard configuration

Transmitters are factory calibrated to customer's

specified range. Calibrated range and tag number are

stamped on the tag plate. If a calibration range and tag

data are not specified, the transmitter will be supplied

with the plate left blank and configured as follows:

Engineering Unit kPa

Output scale 0 % Lower Range Limit (LRL)

Output scale 100 % Upper Range Limit (URL)

Output Linear

Update time 16 s

Tag Blank (up to 32 alphanumeric

characters - long;

only 8 visible on display - short)

Optional LCD display PV in kPa; output in

percentage on bargraph

Any or all the above configurable parameters, including

Lower range–value and Upper range-value which must be

the same unit of measure, can be easily changed using the

HART hand–held communicator or by a PC running the

configuration software with DTM for 266 models. The

transmitter database is customized with specified flange

type and material, O–ring and drain/vent materials and

meter code option.

Custom configuration (option N6)

The following data may be specified in addition to the

standard configuration parameters:

Descriptor 16 alphanumeric characters

Message 32 alphanumeric characters

Date Day, month, year

Transmitter with PROFIBUS PA

communication

Standard configuration

Transmitters are factory calibrated to customer’s

specified range. Calibrated range and tag number are

stamped on the tag plate. If a calibration range and tag

data are not specified, the transmitter will be supplied

with the plate left blank and configured as follows:

Measure Profile Pressure

Engineering Unit kPa

Output scale 0 % Lower Range Limit (LRL)

Output scale 100 % Upper Range Limit (URL)

Output Linear

Hi-Hi Limit Upper Range Limit (URL)

Hi Limit Upper Range Limit (URL)

Low Limit Lower Range Limit (LRL)

Low-Low Limit Lower Range Limit (LRL)

Limits hysteresis 0.5 % of output scale

PV filter 0 s

Address (set by local key) 126

Tag PI000 (up to 32 alphanumeric

characters; only 8 visible on

display)

Optional LCD display PV in kPa; output in percentage

on bargraph

Any or all the above configurable parameters, including

the range values which must be the same unit of measure,

can be easily changed by a PC running the configuration

software with DTM for 266 models.The transmitter

database is customized with specified flange type and

material, O–ring and drain/vent materials and meter code

option.

Custom configuration (option N6)

The following data may be specified in addition to the

standard configuration parameters:

Descriptor 32 alphanumeric characters

Message 32 alphanumeric characters

Date Day, month, year

...Specification – configuration

Transmitter with FOUNDATION Fieldbus

communication

Standard configuration

Transmitters are factory calibrated to customer’s

specified range. Calibrated range and tag number are

stamped on the tag plate. If a calibration range and tag

data are not specified, the transmitter will be supplied

with the plate left blank and the analog input function

block FB1 is configured as follows:

Measure Profile Pressure

Engineering Unit kPa

Output scale 0 % Lower Range Limit (LRL)

Output scale 100 % Upper Range Limit (URL)

Output Linear

Hi-Hi Limit Upper Range Limit (URL)

Hi Limit : Upper Range Limit (URL)

Low Limit Lower Range Limit (LRL)

Low-Low Limit Lower Range Limit (LRL)

Limits hysteresis 0.5 % of output scale

PV filter time 0 s

Tag PI000 (up to 32 alphanumeric

characters; only 8 visible on

display)

Optional LCD display PV in kPa; output in percentage

on bargraph

The analog input function block FB2 and FB3 are

configured respectively for the sensor temperature

measured in °C and for the static pressure measured in

MPa.

Any or all the above configurable parameters, including

the range values, can be changed using any host

compliant to FOUNDATION fieldbus. The transmitter

database is customized with specified flange type and

material, O–ring and drain/vent materials and meter code

option.

Custom configuration (option N6)

The following data may be specified in addition to the

standard configuration parameters:

Descriptor 32 alphanumeric characters

Message 32 alphanumeric characters

Date Day, month, year

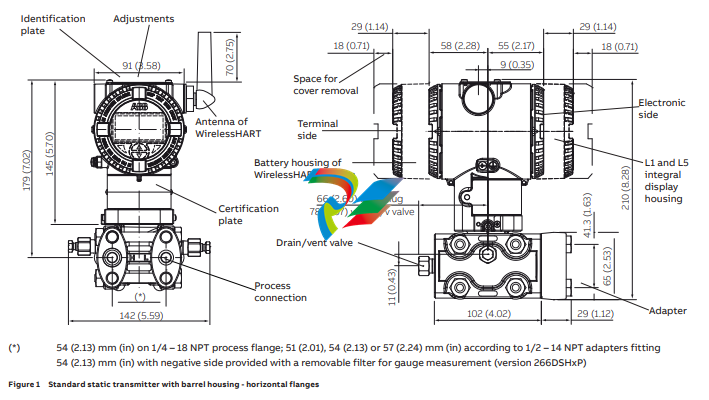

Dimensions

(not for construction unless certified) – dimensions in mm. (in.)

.png)

.png)

.png)