schneiderFoxboro™ DCS Field Mounted Intelligent Enclosure PSS 41H-2I20 Product Specification November 2019

temperatures up to 55° C (131° F), natural convection is supplemented by two

redundant fans that circulate air within the sealed enclosure.

The fans and temperature within the enclosure are monitored by the Enclosure

Monitoring Unit (EMU) that provides a diagnostic alarm on fan deterioration or

enclosure over temperature.

Leave a minimum of 150 mm (6 in) space between adjacent cabinets or a cabinet and

a wall, to allow the flow of air to cool the cabinet.

Cable Entry

Bottom cable entry for power, communication, and field cables is through customer

supplied cable glands that maintain the enclosure protection classification, or optional

factory fitted Multi Cable Transit (MCT).

Modular Baseplate Mounting

The enclosure contains two 8-position standard 200 Series modular baseplates for

Foxboro DCS Fieldbus Modules (FBMs), and two 2-position baseplates for the

FCM2F10s. These are mounted on two vertical DIN rails as shown in Figure 1, page

7. The FBM baseplates include signal connectors for the FBMs, redundant

independent DC power connections, system cable connections, module fieldbus

connections, and time synchronization connections.

For more information on the modular baseplates, see Standard 200 Series

Baseplates (PSS 41H-2SBASPLT).

Field Termination Assemblies

Termination Assemblies (TAs) are installed on the DIN rails mounted at the sides of

the FBM baseplates. The Universal I/O modules are connected to the TAs with preinstalled system cables.

The TAs are supplied with redundant 24 V DC, protected by fuses that are monitored

by the Fuse Monitoring Unit (FMU).

The enclosure is shipped with TAs fitted with passive feed-through signal conditioners

which you can replace with the signal conditioners listed in the section Termination

Assemblies and Signal Conditioners, page 8.

Power Distribution Architecture

The enclosure provides a redundant 24 V power system using two FPS480-24 power

supplies fed by independent sources. Power wiring is routed through the bottom of the

enclosure. The input power connects to the primary and secondary entry terminal

blocks for main and backup power.

Electrical fuses are monitored by the Fuse Monitoring Unit (FMU) and an open fuse

indication from the FMU is wired into the Enclosure Monitoring Unit (EMU) through the

Alarm Distribution Assembly.

Grounding

All enclosure structural elements are integrally grounded by the enclosure design to

meet the appropriate industry regulations and standards. The enclosure is equipped

with two instrument earth bars. It also has a protective connection point at the outside

bottom of the enclosure for customer grounding purposes. Field wiring shields can be

terminated either to the Terminal Assemblies or to the instrument ground bus bar.

Spare signal wires and shields can be terminated either to the Terminal Assemblies or

to the instrument ground bus bar.

Enclosure Diagnostic Alarms

The EMU provides an alarm for power supply failure detection, fuse failure detection

via the FMU, door open, fan deterioration, and enclosure over temperature. The EMU

provides a composite diagnostic alarm from a graduated analog signal that indicates

individual alarms and is prewired to a Universal I/O module channel for indication and

alarm.

Enclosure Security

The enclosure can be physically locked with a customer-supplied padlock to provide

physical security. The enclosure is also fitted with a door open switch that is alarmed

via the Enclosure Monitoring Unit to alert plant personnel.

Enclosure Options

The enclosure can be configured with the following options:

• 120 V AC or 230 V AC supply

• Customer supplied cable glands or factory fitted Multi Cable Transit (MCT)

• Termination Assembly selection for IS, Non-IS, and manufacturer

• 64 simplex UIO points, 64 redundant UIO points, or 48 simplex and 16 redundant

UIO points

• Third party communications through FBM232 modules for simplex Ethernet or

FBM233 modules for redundant Ethernet

• Fiber optic connection to the HDLC Fieldbus using FCM2F10 modules

• Extended twinaxial connection to the HDLC Fieldbus using FBI200 modules

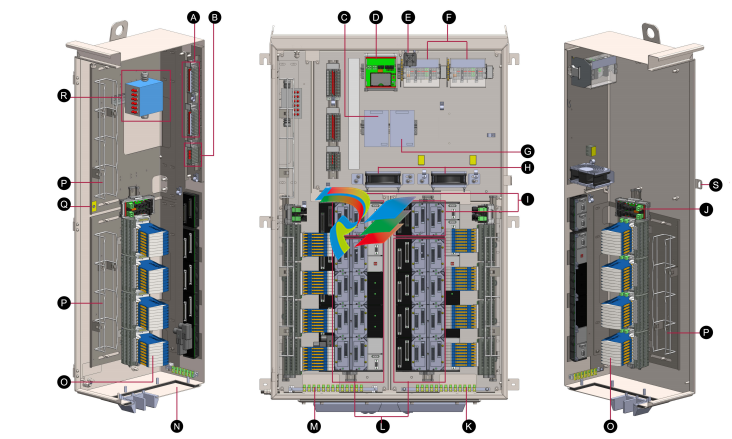

Figure 1 - Interior View of the Enclosure

Legend

A 24 V DC Power Distribution Assembly K Instrument Ground Bar

B Alarm Distribution Assembly Terminals L Baseplate 8-Position FBM

C Primary Power Supply M Instrument Ground Bar

D Enclosure Monitoring Unit N Cable Entry (Blank Gland Plate)

E Door Open Switch O Termination Assemblies (Phoenix Contact shown)

F Power Entry Terminal Blocks P Wire Tray, 50 mm x 50 mm x 403 mm (2 in x 2 in x 15.9 in)

G Secondary Power Supply Q Electro Static Discharge Bonding Point

H Fans for internal air circulation R Fiber-Optic Patch Panel

I Baseplate 2-Position FCM S Lock for Customer-Supplied Padlock

J Fuse Monitoring Unit

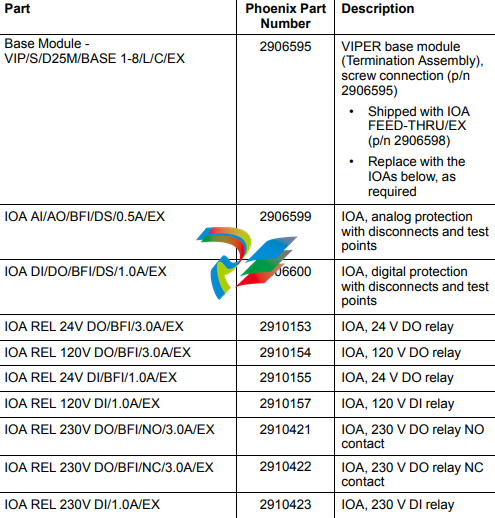

Termination Assemblies and Signal Conditioners

The following tables list the Termination Assemblies and Signal Conditioners

supported. You can select them as required at the time of ordering the enclosure.

Table 1 - Supported Phoenix Termination Assemblies and Signal Conditioners

.png)

.png)

.png)