DeltaV™ M-series Traditional I/O

Decreases capital equipment costs

Decreases installation time and expense

Increases productivity

Increases process availability

Introduction

Traditional I/O is a modular subsystem that offers flexibility

during installation. It’s designed to be installed in the field,

near your devices. Traditional I/O is equipped with function

and field wiring protection keys to ensure that the correct

I/O card is always plugged into the corresponding terminal

block. Modularity, protection keys, and plug and play

capabilities make DeltaV™ Traditional I/O a smart choice

for your process control system.

Benefits

Decreases capital equipment costs

Full system modularity. The Traditional I/O

subsystem was designed with your investment in mind. All

components are fully modular and may be installable

under power.1 You add I/O interface carriers and I/O

interfaces in groups of 4, 8, 16, or 32 channels as you

need them. The modular design enables you to purchase

the exact amount of I/O cards, 8-wide carriers,

power/controllers, and 2-wide carriers you need and add

more DeltaV I/O as your system grows.

Reduced system footprint. The DeltaV system’s

state-of-the-art form factor design of the I/O components

enables you to mount the I/O interface carrier in a junction

box in the field so you significantly reduce the footprint of

your equipment and increase valuable control room space

for other uses.

Installation. Save on wiring expenses by installing

Classic Instrumentation in the field, near the actual field

devices. Mounting the controller with the I/O further

reduces your wiring expenditures by eliminating the need

for long runs of multi-cores. The integrated design of the

Traditional I/O subsystem can eliminate the need for

marshaling panels. This saves you even more in your total

capital costs.

The provision of in-line fuses and bussed power saves on

installation costs compared with external fuses and power

distribution.

Decreases installation time and expense

Plug-and-play installation saves money. All

Traditional I/O components plug into the I/O interface

carrier. You can install the I/O interface carriers to manage

anticipated growth and postpone the I/O interfaces until

you’re ready to install your additional field devices.

Phased installation saves time. As soon as you

mount the I/O interface carrier, you’re ready to begin

installing the field devices. I/O terminal blocks plug directly

onto the I/O interface carrier. There is no need to have the

I/O cards installed.

1 Refer to Zone 2 installation instructions (12P2046) and/or

Class 1 Division 2 installation instructions (12P1293) for

details.

Traditional I/O terminal block.

Keys. Traditional I/O interfaces and terminal blocks have

I/O function keys. These keys ensure that the correct I/O

card is always plugged into the corresponding terminal

block. It’s incredibly easy to use and gives you time to do

more.

This design enables you to initially install Traditional I/O

quickly and efficiently. When you need to replace an I/O

card, the function key design ensures that you will always

install it correctly. This keying system provides a safety

measure by preventing the wrong I/O interface’s being

installed.

Increases productivity

Real-time, online equipment additions. Online

addition of new I/O interfaces means your process does

not get interrupted. As new equipment is added, the

DeltaV Explorer acknowledges it and assigns it basic

configuration.

Increases process availability

1:1 Redundancy for Traditional and HART I/O

cards. DeltaV redundant I/O uses the same Series 2 I/O

cards as non-redundant I/O. This allows you to leverage

your investment in installed I/O and in I/O spares. No

additional configuration is needed when using a redundant

channel. The redundant terminal blocks provide the same

field wiring connections as simplex blocks, so there is no

extra wiring needed.

Autosense of redundancy. DeltaV autosenses

redundant I/O, which greatly simplifies the task of adding

redundancy to the system. The redundant pair of cards is

treated as one card in the system tools.

Automatic Switchover. Should a primary I/O card fail,

the system automatically switches to the "standby" card

without user intervention. The operator is given clear

notification of a switchover at the operator display

Product Description

The Traditional I/O subsystem includes:

I/O interface carrier (a DIN rail surface mounted) on

which all I/O related components are installed.

Bulk AC to 24 VDC power supply for field devices.

An I/O interface consisting of an I/O card and an I/O

terminal block.

A variety of analog and discrete I/O cards enclosed in

a common form factor that easily plugs into the I/O

interface carrier.

A variety of I/O terminal blocks mounted on the I/O

interface carrier that can be pre-wired before I/O card

installation.

A Traditional I/O card easily plugs into an I/O carrier

I/O Cards

A variety of analog and discrete I/O cards are available to

meet your specific requirements. The following cards

support simplex or redundant installation:

AI 4-20 mA HART 8 channels

AO-4-20 mA HART 8 channels

DI, 24 VDC Dry Contact, 8-channels

DO 24 VDC High Side, 8-channels

The following I/O cards are supported in simplex format to

meet your field wiring needs.

AI 4-20 mA HART 16 channels

AI Isolated, 4 channels

RTD, 8-channels

Thermocouple, 8- channels

Millivolt, 8-channels

DI, High Density, 32-channels

DI 24 VDC Isolated, 8-channels

Multi-Function, 4 channels (Isolated DI)

Sequence of Event, 16 channels (DI 24 VDC)

DI 120 VAC Low Side Detection, 8-channels

DI 120 VAC Isolated , 8-channels

DO, High Density, 32-channels

DO 24 VDC Isolated, 8-channels

DO 120/230 VAC High Side, 8 channels

DO 120/230 Isolated, 8 channels

All I/O cards are enclosed in a common form factor that

plugs into the I/O interface carrier. The housing is clearly

labeled with the enclosed I/O card type. All cards have

power and internal error indicators. Eight channel cards

have clearly visible channel status LEDs.

All cards meet ISA G3 corrosion specifications by the

careful selection of superior electronic components and

the use of conformal coating.

Pulse Counters are available on most DI cards. The

supported maximum frequency varies from 0.1 Hz on AC

signals to 75 or 120 Hz on 24 VDC inputs. For higher

pulse counts up to 50 KHz, use the Multi-Function card’s

high speed pulse input.

DeltaV provides control module level time stamping for log

events and alarms. For greater event resolution the 16

channel Sequence of Events DI card can provide signal

driven events to a resolution of +/- 0.25 ms per card, or

within 1 ms per controller. Please refer to the Sequence

of Events PDS for more information on Sequence of Event

data collection and system options for this feature.

I/O Card Redundancy

Redundant I/O cards are available for critical applications.

The same card can be used in simplex or redundant

applications. When installed on a two-wide redundant

terminal block, the cards are recognized as a redundant

pair by the controller. The controller scans each card and

determines which card is acting as the active interface.

When a fault is detected, the system automatically

switches to the standby I/O card.

DeltaV Control modules reference simplex and redundant

I/O channels identically and there is no special

configuration required to take advantage of redundancy.

Switchover of a redundant I/O card is completed within

two scans of the I/O bus. Make-before-break contacts

ensure digital field instruments remain powered and the

process is undisturbed. Analog output signals are briefly

driven by both cards for < 5 ms during switchover of the

card.

Hardware Alerts automatically report hardware integrity

errors for both the primary and secondary cards. Any

event that causes a switchover is also reported

automatically through the system hardware alerts and is

logged in the Event Chronicle.

Events that can cause a switchover include.

Hardware failure within the active card.

Communications failure between the active card and

the controller.

Detection of a fault in the field wiring

A switchover may also be initiated from the diagnostics

explorer, and the health and status of both cards and their

channels are available in the diagnostics explorer.

The system automatically commissions a new standby

card. In safe areas, failed cards can be replaced under

power. In hazardous areas, appropriate installation

procedures must be followed.

Fused 8-Channel Terminal Block

AI 8-Channel Terminal Block

AI 16-channel Terminal Block

4-wire AI 16-channel Terminal Block

Discrete 32-Channel Terminal Block

Isolated Input Terminal Block

RTD/Resistance Terminal Block

Thermocouple Terminal Block

The following redundant I/O terminal blocks are available

on some I/O interfaces, allowing a pair of cards to be

installed as a redundant pair.

Redundant AI 8-Channel Terminal Block

Redundant AO 8-Channel Terminal Block

Redundant Discrete 8-Channel Terminal Block

The table on the following page lists the compatible

terminal blocks for each card, along with the cards unique

key positions. The first terminal block listed is the

recommended terminal block.

In addition to standard signal wiring, some cards may also

be ordered with Mass Termination blocks that allow these

cards to be connected to M-Series Mass Connection

Solution or to third party wiring solution, mounted in an

adjacent cabinet in order to meet special signal

conditioning or for optimizing field wiring solutions. Please

refer to the PDS M-series Mass Connection Solution or to

the Alliance Program website for details on approved 3rd

party products.

10-pin Mass Termination Block

16-pin Mass Termination Block

24-pin Mass Termination Block

40-pin Mass Termination Block

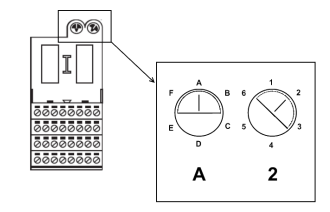

The keying mechanism consists of two keying posts that

rotate and lock into the terminal block base. Each post

has 6 positions: A-F and 1-6. Each card is assigned a

unique key which is marked on the side of the I/O card:

Terminal Block keying example

The keys prevent installation of an incorrect card, and the

graphical information on the card makes it easy to

determine if a keyed slot will accept a particular card.

There are 8 different I/O terminal blocks available to meet

the wiring needs of field signals.

8-Channel Terminal Block

.png)

.png)

.png)