SHINKAWAVM-5 SERIES MONITOR MODEL VM-5K DUAL VIBRATION MONITOR INSTRUCTION MANUAL

7-2 BASIC KEY OPERATIONS

• (SET) key : Used to change the display mode of the LCD display and to

finalize input.

• (UP) key : Used to change parameters and increment set values.

• (DOWN) key : Used to change parameters and decrement set values.

• (RESET) key : Used to reset alarms set to self-holding.

• Alarm reset is not possible until the output condition has been released.

• An alarm lamp set flashing by the First-out Display function cannot be reset.

(Reset by shorting between the RES and COM terminals.)

• (CHECK) key : The CHECK key is used to adjust the gain while changing set

values with the UP and DOWN keys.

For example, if the CHECK key is pressed while the value 0.1

appears on the MEAS 2 LED display, a value corresponding to the

measurement range × 0.1 can be set.

• Each operation of the CHECK key will multiply the multiplier by 10.

: When the CHECK key is pressed during normal monitoring, the

monitor will go through self-diagnosis in the following sequence :

(1) LCD, LED display test (all lamps light)

(2) Self-diagnosis

(3) Display of diagnosis result (Normal) (Abnormal)

• The diagnosis result for CH1 is indicated on the MEAS 1 display and that for CH2 on

the MEAS 2 display.

• If an abnormality is found as a result of self-diagnosis, the error content is displayed

after approx. 3 seconds.

• In case of more than one abnormality, error contents are displayed at 3-second

intervals.

Error content display

Check items Display

CH1 OK (input abnormal) alarm HIGH

CH2 OK (input abnormal) alarm HIGH

CH1 OK(input abnormal) alarm LOW

CH2 OK(input abnormal) alarm LOW

CH1 A/D input 5V side over

CH2 A/D input 5V side over

CH1 A/D input 0V side over

CH2 A/D input 0V side over

For safe operation.....

Thank you for using our VM-5 Series Monitor. SHINKAWA Sensor Technology applies strict quality control

and inspections to ensure the high reliability of its products.

This instruction manual contains descriptive information, specifications, and operating, setting, and adjusting

procedures.

Please study the contents of this manual and related manuals thoroughly before installing or operating the

equipment, and keep it handy for future reference.

"Safety Conventions"

Please thoroughly study the following section entitled "Safety Conventions" before operating the

equipment.

The safety symbols explained in this section are placed outside the left margin next to the text to which they

apply.

This unit is designed for use by specialists or persons thoroughly familiar with the field.

Make sure that the end user receives the Instruction Manual delivered with this unit.

Before use.....

When the unit is received, inspect it for damage suffered in transport and check

whether it is the item you ordered. In the unlikely event that it was damaged in transport

or does not function according to specifications, please contact the SHINKAWA Office

or dealer nearest you.

Store the unit under the ambient conditions given in the specification.

Avoid places where it is exposed to high humidity or corrosive gases.

Make it a rule to follow the instructions given in this manual.

This manual contains important information designed to prevent personal injury and property damage, and

ensure safe operation of the equipment.

Familiarize yourself with the signs and symbols explained below before proceeding to read the manual, and

observe the instructions given.

■ Explanation of signs

Symbols Explanation

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. It may also be used to permit for property-damage-only accidents.

◊ "Serious injury" refers to such injuries as loss of eyesight, injuries, burns (due to heat or cold), electric

shock, fractures, and poisoning, that have permanent aftereffects and require hospitalization or long-term

outpatient treatment.

◊ "Moderate or minor injury" refers to such injuries as burns and electric shock that do not require

hospitalization or long-term outpatient treatment. "Property-damage-only accidents" refers to

consequential damage related to destruction of property and damage to the equipment.

■ Explanation of symbols

Symbols Explanation

Indicates a prohibited action.

Details are given in the text next to the symbol.

Indicates a mandatory action.

Details are given in the text next to the symbol.

To ensure safe use of this equipment, strictly observe the safety precautions provided in this manual, as well

as installation methods and methods of use stipulated by laws and regulations. SHINKAWA Sensor

Technology will not be liable for damage, etc. due to methods of use contravening to the instructions provided

here.

■ Safe use

WARNING

Make sure to ground.

May cause electric shock or malfunction.

Make sure to turn the power off before any wiring work.

Will cause electric shock.

CAUTION

Connect the input signal within the voltage range described in the

specification to the input terminals.

Will cause damage and malfunction of the instrument.

Install the monitor unit and its relay module unit in the same location in the

instrument rack.

Will cause damage to the instrument and malfunction of the turbine monitoring system.

A printed circuit board and electronic products may receive damage with

the static electricity of a human body.

Touch the metal part once and discharge your static electricity before

dealing with it.

Will cause damage and malfunction of the instrument.

Do not touch parts and soldered surfaces of the monitor unit.

Will cause damage and malfunction of the instrument.

The monitor unit is a precision instrument.

Take care not to expose it to excessive shock or vibration.

Do not change the parameter settings during operation.

May cause unexpected alarm output.

Do not pull out the face plate during operation.

Will cause damage to the instrument and malfunction of the turbine monitoring system.

Do not measure insulation resistance and dielectric strength other than

those at places specified.

Will cause damage to the instrument.

Do not remodel this monitor unit without permission.

Otherwise the guarantee can not be made.

■ EMC(Electro-magnetic compatibility)

The EMC of each VM-5 Series monitor is evaluated by various noise tests.

However, its characteristics may vary with on environmental conditions such as the magnitude of noise,

ambient temperature, humidity and the arrangement of equipment.

For the above reason, when operating the monitor, please observe the following CAUTION.

CAUTION

The monitor unit should be operated by specialists or personnel who have

knowledge of it.

When a shielded cable is used, the length of the unshielded cable section

should be less than 100mm (3.937in REF.).

For each relay used near this monitor unit, devices related to this monitor

unit or signal cables connecting the monitor unit and these devices, install

a surge killer.

Firmly tighten each screw used for mounting each unit. In additional,

always close the face plate for the monitor unit, then fix it with knurled

screws.

In order to prevent the system from its malfunction when the monitor unit

fails, provide the systematic interlock function.

Do not wire input signal cables in parallel with control and power cables.

It is recommended that separated wire ducts be used for these cables.

Do not use any radio equipment near the monitor unit.

■ Noise filter

Noise transmitted through in each cable may be rejected to some extent by inserting a ferrite core in the cable

(note 1).

If the cable passes through noisy surroundings, it is recommended that such a noise prevention device is used.

GENERAL INFORMATION

OVERVIEW

This is a highly reliable dual channel vibration monitor which monitors the shaft vibration of

rotating machinery.

Both a 10-slot rack mounting type and a single-unit independent type with a built-in power supply

are available so that it can respond flexibly to any system design from medium and small scale

rotating machinery to TSI. The monitor accepts signals detected by a transducer and displays them

on LCD.

It is also possible to set ALERT and DANGER alarm levels independently to detect machine

failures early on and inform the operator of these failures. It has a built-in self-diagnostic function

to inform the operator of input transducer failures, thereby preventing rotating machinery from

false shutdowns.

FEATURES

• Conforms to API St’d 670

• The monitor is available as a single unit independent type or a rack mounting type.

• Has a self-diagnostic function.

• Allows the operator to change each setting even in the field.

• Important information such as measured value, alarm set value and gap voltage is normally

displayed.

• Can isolate recorder output (option).

• LED display / contact output (DANGER / ALERT alarm).

• LED display / contact output (Input abnormal alarm).

• For alarm output wiring proceed as described in the instruction manuals for the

VM-5G Single Unit Instrument Rack and VM-5Y Relay Module Unit used in

combination with this monitor unit.

• If megger test is made on the signal cable between transducer and monitor,

disconnect the cable from transducer and monitor.

Be sure to discharge the charged electric load before connecting the cable to the

transducer and monitor.

If this caution is not adhered to, the transducer and monitor could be damaged.

FIRSTOUT DISPLAY

• Installation in VM-5H3, 5W1 Instrument Rack

Causes the alarm lamp of the channel that first output alarm to flash.

• Installation in VM-5G Single Unit Instrument Rack

Causes the lamp of the alarm first output to flash.

For details refer to 7. PARAMETER SETTING on page 19.

• An alarm lamp set flashing by the First-out Display function cannot be reset by

pressing the RES (RESET) key.

Reset by shorting between the RES and COM terminals.

• It is necessary to keep short circuit of the terminals for more than one (1) second to

operate these functions.

5-9 SEQUENCE FUNCTION

To prevent alarm output due to excessive vibration generated during starting and stopping of the

machine, this function expands the DANGER alarm and ALERT alarm set ranges by shorting

between the SEQ. and COM terminals.

• The machine is not protected if the alarm set value exceeds 110% of the monitor

range due to operation of the sequence circuit.

• It is necessary to keep short circuit of the terminals for more than one (1) second to

operate these functions.

5-10 BYPASS FUNCTION

Used to disable alarm output while setting the alarm parameters, or during maintenance/inspection

work. The alarm BYPASS lamp flashes or lights during this operation. Set by turning the BYPASS

switch to ON.

• While BYPASS FUNCTION is in operation, the machine is not protected.

5-10-1 DANGER BYPASS

Cuts off DANGER alarm. While cut off, the DANGER alarm and BYPASS lamps are flashing.

This function is activated by means of the DANGER BYPASS switch. For details refer to 7.

PARAMETER SETTING on page 19.

• If mounted in the VM-5H3 or VM-5W1 Instrument Rack, all units in the instrument

rack can be set collectively to DANGER BYPASS.

For details refer to VM-5H3 or VM-5W1 Instrument Rack instruction manual.

5-10-2 CH1 BYPASS

DANGER alarm, ALERT alarm, OK alarm, display and recorder output of CH1 are cut off.

While cut off, the OK lamp goes off and the BYPASS lamp lights.

This function can be activated by means of the CH1 BYPASS switch.

For details refer to 7. PARAMETER SETTING on page 19.

5-10-3 CH2 BYPASS

DANGER alarm, ALERT alarm, OK alarm, display and recorder output of CH2 are cut off.

While cut off, the OK lamp goes off and the BYPASS lamp lights.

This function can be activated by means of the CH2 BYPASS switch.

For details refer to 7. PARAMETER SETTING on page 19.

5-11 POWER ON TIMER MODE

Operates for approx. 5sec. after the power is turned on. (for approx. 25 sec. in case of pk-pk

detection). In this mode, all alarm functions are disabled and the BYPASS and OK lamps flash.

5-12 ALARM RELAY MODE

Each alarm contact can be set to either normally de-energized or normally energized.

Alarm contact operation

Monitor power Monitor power ON

OFF Normal state Alarm state

NO contact NORMALLY DE-ENERGIZED OPEN OPEN CLOSE

NO contact NORMALLY ENERGIZED OPEN CLOSE OPEN

NC contact NORMALLY DE-ENERGIZED CLOSE CLOSE OPEN

NC contact NORMALLY ENERGIZED CLOSE OPEN CLOSE

For details refer to 7. PARAMETER SETTING on page 19.

5-13 ALARM RESET MODE

The automatic reset of all alarm output and alarm lamps can be set when the measured value or

input signal return to normal. In addition to above, the self-holding function can be also set for

each alarm output that holds the alarm condition until reset by setting RES key (inside of the front

panel) or by shorting between RES and COM terminal.

• Alarm reset is not possible until the output condition has been released.

• It is necessary to keep short circuit of the terminals for more than one (1) second to

operate these functions.

For details refer to 7. PARAMETER SETTING on page 19.

5-14 MONITOR OUTPUT

For vibration analysis, the vibration waveform signal is output from the BNC connector on the

monitor front panel and buffer output terminal on the rear panel (VM-5G Single Unit Instrument

Rack, VM-5Y Relay Module Unit) via a buffer amplifier.

5-15 RECORDER OUTPUT

An analog signal proportional to the vibration value is output from the terminal block.

5-16 SELF-DIAGNOSTIC FUNCTION

Any failures in the input system, such as sensor short-circuit or imperfect connections, are detected,

then an OK alarm is contact-output and (simultaneously), the OK lamp flashes.

5-17 POWER SEQUENCE

If mounted in the VM-5G Single Unit Instrument Rack, the secondary power supply can be cut off

by shorting between the P-S (POWER SEQUENCE) and COM terminals.

• This function can be used for pulling out or pulling in the monitor unit at the

emergency time. However, do not use for long time shorting of more than one (1)

minute or turning on and off repeatedly.

Also, the parallel connection for the two (2) or more monitors should not be allowed.

5-18 TIMED OK CHANNEL DEFEAT

When on setting, when OK alarm is output, DANGER alarm, ALERT alarm, display, and recorder

output are disabled. DANGER ALERT, display and recorder output are not disabled, in case of

excessive signal input from sensor.

For details refer to 7. PARAMETER SETTING on page 19.

5-19 SUPPRESSION FUNCTION

This function can suppress the measurement around zero measurement point of the monitor by the

effect of the piping vibration or electric noise, etc. during the machine stopping.

The suppression can be set at 0.0 to 10.0 % (0.1% step) of the monitor range.

ex.) If the suppression is set at 2.0%, monitor measurement less than 2.0% shall be output as 0.0%

2 DESCRIPTION OF PARTS 1 LCD display This LCD display serves for display of measured values, alarm set values, sensor set gap voltage value and other set values. 2 DANGER alarm lamp Lit when DANGER alarm is output. 3 ALERT alarm lamp Lit when ALERT alarm is output. 4 OK lamp Flashes (steady light in normal condition) when OK (input abnormal) alarm is output. 5 BYPASS lamp Flashes during DANGER bypass and lights during CHANNEL bypass. 6 Monitor output connector This is a BNC output connector for connection of an oscilloscope to observe the waveform, or for output to other devices such as an analyzer. The input signals from the transducers are output through a buffer amplifier. • Make sure to insulate the monitor output against earth. If not insulated, a 2-point earth system results, which may cause noise interference. 7 Name plate 8 Tag, Ser. No. plate The TAG NO. and SER.NO. are entered on this plate. 9 LCD board 10 Slide frame 11 Main board frame 12 Main board 13 DIN connector (64pin) Connector for connection to the VM-5G Single Unit Instrument Rack or VM-5H3 or VM-5W1 Instrument Rack.

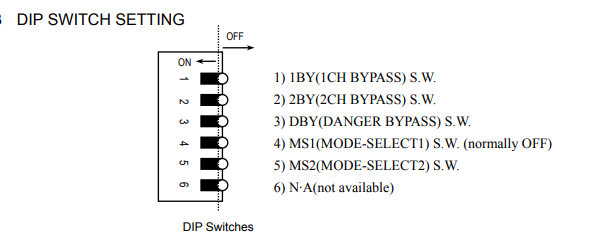

1) 1BY (CH1 BYPASS) Switch

"ON" To select CH1 BYPASS function.

"OFF" Normal monitoring

2) 2BY (CH2 BYPASS) Switch

"ON" To select CH2 BYPASS function.

"OFF" Normal monitoring

3) DBY (DANGER BYPASS) Switch

"ON" To select DANGER BYPASS function.

"OFF" Normal monitoring

4) MS1 (MODE-SELECT1) Switch (normally OFF)

• Set normally to “OFF”. Parameter setting mode is disabled.

5) MS2 (MODE-SELECT2) Switch

“ON”

For setting the alarm reset mode, alarm delay time, alarm relay mode, first-out display,

and timed OK channel defeat.

Also enables setting the address when used in combination with the VM-5H3 or 5W1

Instrument Rack and VM-5P1,2 Communication/Phase Marker Unit or VM-53 Dual

Communication Unit. To PARAMETER SETTING 1.

“OFF”

For changing the set values for DANGER alarm and ALERT alarm, and GAP ALARM,

and adjusting measured value and recorder output zero span.

To PARAMETER SETTING 2.

.png)

.png)

.png)