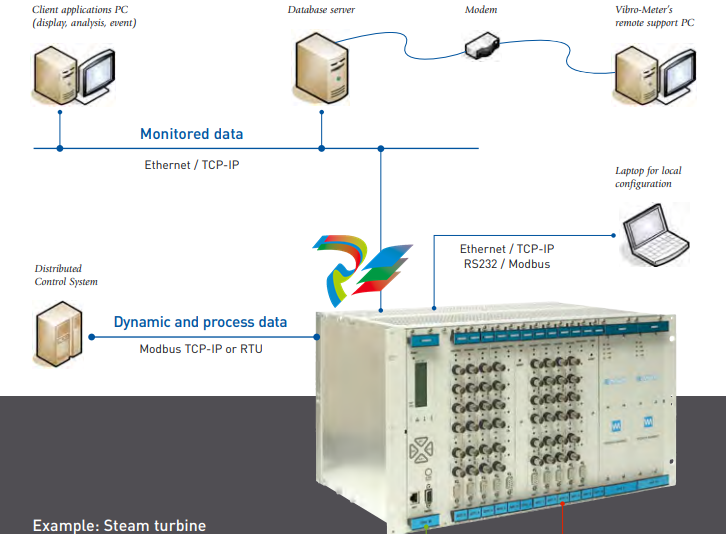

parkerVM600 systems: Integrated machinery protection, condition and performance monitoring

processing and communication circuitry.

We also have a complete in-house capability to test and qualify

state-of-the-art monitoring systems. We are able to simulate

complete machinery applications in our labs, to meet the latest

industry requirements.

To guarantee the uniqueness of our technology and know-how,

we continuously invest in training, technical innovation and first

class simulation and design software. To support our continuous

innovative effort, we have ongoing collaborations with several

renowned universities and industrial partners.

Manufacturing

Since the 80’s Vibro-Meter has had a Production Planning

System, enabling high quality and productivity objectives to be

achieved.

Our large and modern manufacturing facility in Fribourg

(Switzerland) is designed to ensure the highest quality standards

and organized to efficiently produce large scale orders as well as

small batches.

Skilled and experienced production staff can manufacture a

series of products adapted to fulfil the special requirements of

our customers.

Qualification & quality insurance

The quality and reliability of Vibro-Meter’s products has been

widely recognized since our entry into the aviation sector in the

70’s. This is when our Quality System was put in place. Our latest

BS EN ISO9001:2000 certification was awarded in April 2007.

Our continuous improvement culture applies to everything we

undertake. All employees strive to consistently develop, maintain

and improve our quality management system at every

opportunity. Customers are the focus of everything we do.

Case studies

Siemens uses Vibro-Meter’s VM600 to protect and

remotely monitor the world’s most powerful gas

turbine (GT).

“Irsching 4” near Ingolstadt (Germany) is the test

power plant for the new SGT5-8000H, which is the

world’s most powerful GT with a 340MW simple cycle

power output. The GT was first fired in December

2007. After an 18-month trial operation period, it will

be expanded to become a 530 MW combined cycle

power plant (CCPP) and will be handed-over by

Siemens to E.ON for commercial operation in 2011.

This technologically leading CCPP will achieve an

efficiency of 60%, which is a new world record. As a

result, it will emit approximately 40000 tons of CO2

per year less than comparable existing plants.

Monitoring vibrations and GT’s combustion is a proven

way to contribute to reliable GT operation, with the

target of reaching the highest possible efficiency and

lower emissions. Siemens has chosen Vibro-Meter to

provide the monitoring system for the SGT5-8000H.

Our integrated solution includes dynamic pressure

sensors (CP), as well as relative and absolute

vibration sensors (CA and TQ) and a VM600 protection

& condition monitoring system.

All data collected by the VM600 are continuously

transferred to Siemens’ Intranet, interfaced with their

Win_TS system (a global networked plant diagnostic

platform). With these tools, experts working in

Siemens’ Diagnostic Centres (Erlangen and Orlando)

and Research-and-Engineering Centres (Erlangen,

Berlin, Muelheim, Orlando and others) can for

example remotely calculate balancing for turbines

located in plants all over the world. Using this

information, staff on-site can balance a turbine

without the need for an on-site visit by experts, saving

time and cost.

Vibro-Meter is proud to contribute to Siemens’

leading-edge technology and their outstanding

support to customers.

Hydro turbine-generator: “Shipshaw” Hydro Power Plant (Canada)

Remote condition monitoring (VM600 system, with LS and CA sensors)

Heavy duty gas turbine: “Nhon Trach” combined cycle power plant (Vietnam)

Protection and condition monitoring (VM600 system, with CP, CA and TQ sensors)

Shipshaw Hydro Power Plant (HPP) is owned by the

largest independent producer of hydroelectricity in

Quebec, Rio Tinto Alcan. At the time of construction, the

power plant was the most powerful in the world, with an

output of 896 MW from 12 generators.

Condition monitoring of hydroelectric generators is

critically important to increase efficiency, plan

preventive maintenance and detect wearing of critical

parts.

In Shipshaw HPP, the main control centre is 60 km away

from the plant. The customer’s goal is to ensure

permanent remote monitoring and analysis by their

experts. This reduces on-site human presence and thus

lowers maintenance costs. High speed network access

via optical fibre is established between the control

centre and Vibro-Meters’ VM600 systems in the plant.

Twelve VM600 Systems provide condition monitoring of

vibration and other dynamic measurements (e.g. relative

vibration, axial position, rotating speed, dynamic

pressure and generator’s air gap). Temperatures and

plant process signals are also monitored (e.g. active

power, oil bearings temp., stators temp., ambient temp.,

oil levels, water flow, as well as other flows and plant

data). Furthermore, Vibro-Meter provides air gap

measuring systems for the generator and vibration

measurement chains to monitor bearing vibration in

both generators and turbines.

Alstom uses Vibro-Meter’s VM600 for the first time to

protect and monitor a GT13E2 for a large CCPP in Vietnam.

The Nhon Trach CCPP project will be carried out in

.png)

.png)

.png)