ABB V18345

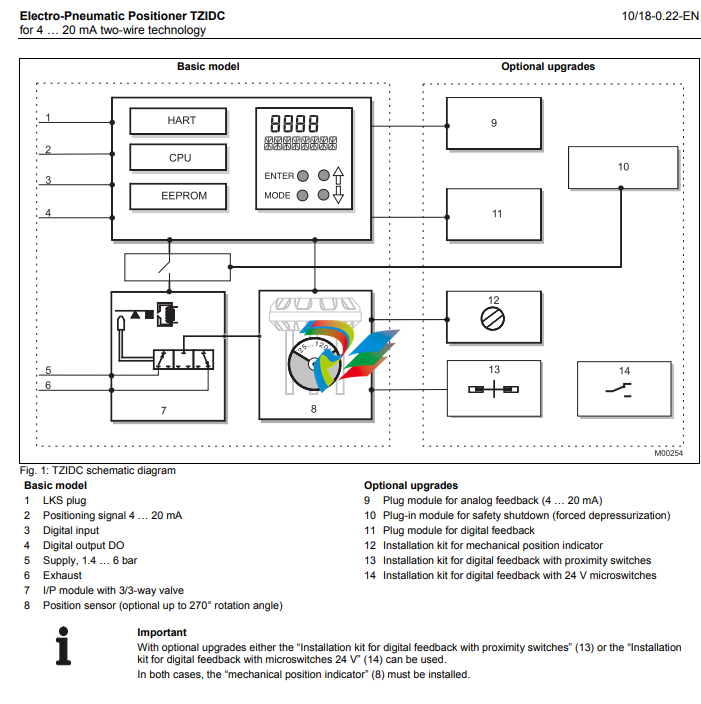

1 Description Pos: 3.2 /==== Wechsel ein- auf zweispaltig ==== @ 0mod_1130421847171_3101.doc @ 3828 Wechsel ein-auf zweispaltig Pos: 3.3 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Kurzbeschreibung/Kurzbeschreibung @ 10mod_1173180169769_3101.doc @ 71118 The TZIDC is an electronically configurable positioner with communication capabilities designed for mounting to pneumatic linear or rotary actuators. It features a small and compact design, a modular construction, and an excellent cost-performance ratio. Fully automatic determination of the control parameters and adaptation to the final control element yield considerable time savings and an optimal control behavior. Pos: 3.4 /Überschriften/1.1/2-spaltig/Pneumatik @ 10mod_1176211138453_3101.doc @ 76683 1.1 Pneumatics Pos: 3.5 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Kurzbeschreibung/Pneumatik @ 10mod_1173180645393_3101.doc @ 71139 a An I/P module with subsequent pneumatic amplifier is used to control the pneumatic actuator. The well-proven I/P module proportionally converts the permanent electrical positioning signal from the CPU into a pneumatic signal used to adjust a 3/3-way valve. The air flow for pressurizing or depressurizing the actuator is continuously adjusted. As a result, excellent control is achieved. When reaching the set point, the 3/3-way valve is closed in center position to minimize the air consumption. Four different pneumatics versions are available: for single-acting or double-acting actuators, each with “fail-safe” or “fail-freeze” function. Pos: 3.6 /Überschriften/1.1.1/2-spaltig/Sicherheitsfunktion "entlüftend" @ 10mod_1176211744343_3101.doc @ 76809 1.1.1 “Fail-safe” function Pos: 3.7 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Kurzbeschreibung/Sicherheitsfunktion "entlüftend" @ 10mod_1176211673796_3101.doc @ 76788 If the electrical power supply fails, the positioner output 1 is depressurized, and the pneumatic actuator’s return spring moves the valve to the defined safe position. In case of a double-acting actuator the second output 2 is additionally pressurized. Pos: 3.8 /======= Spaltenumbruch ======== @ 0mod_1132937966324_3101.doc @ 3831 Pos: 3.9 /Überschriften/1.1.1/2-spaltig/Sicherheitsfunktion "blockierend" @ 10mod_1176211798765_3101.doc @ 76830 1.1.2 “Fail-freeze” function Pos: 3.10 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Kurzbeschreibung/Sicherheitsfunktion "blockierend" @ 10mod_1176211845484_3101.doc @ 76851 If the electrical power supply should fail, the positioner output 1 (and 2, if applicable) is closed and the pneumatic actuator stops (“freezes”) the valve in the current position. If compressed air supply should fail, the positioner depressurizes the actuator. Pos: 3.11 /Überschriften/1.1/2-spaltig/Bedienung @ 10mod_1176211172234_3101.doc @ 76704 1.2 Operation Pos: 3.12 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Kurzbeschreibung/Bedienung (Kommunikationsmöglichkeit) @ 10mod_1173184631054_3101.doc @ 71160 The positioner has a built-in operating panel providing a 2-line LCD and 4 pushbuttons for optimal local configuration, commissioning and operational monitoring. Alternatively, the appropriate configuration program and the available communication option can be used. Pos: 3.13 /Überschriften/1.1/2-spaltig/Kommunikation @ 10mod_1176211201546_3101.doc @ 76725 1.3 Communication Pos: 3.14 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Kurzbeschreibung/Kommunikation @ 10mod_1176212225390_3101.doc @ 76893 The standard TZIDC model has a local communication interface (LKS connector). Additionally, a “HART communication” option for communication via the 20 mA signal is available. Both communications are based on the HART Protocol. Pos: 3.15 /Überschriften/1.1/2-spaltig/Ein-/Ausgänge @ 10mod_1176211233015_3101.doc @ 76746 1.4 Inputs and outputs Pos: 3.16 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Kurzbeschreibung/Ein-/Ausgänge @ 10mod_1176212290390_3101.doc @ 76914 In addition to its input for the analog position set point the TZIDC positioner is equipped with a digital input which can be used to activate various protective functions in the device via the process control system. A digital output allows you to output collective alarms or fault messages. Pos: 3.17 /Überschriften/1.1/2-spaltig/Modularer Aufbau @ 10mod_1176211317984_3101.doc @ 76767 1.5 Modular design Pos: 3.18 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Kurzbeschreibung/ModularerAufbau @ 10mod_1173184783043_3101.doc @ 71181 q The TZIDC basic model can be enhanced at any time by retrofitting optional equipment. Option modules for analog or digital position feedback or a shutdown-module can be installed. Additionally, a mechanical position indicator, proximity switches or 24 V microswitches are available for indicating the position independently of the mother board function.

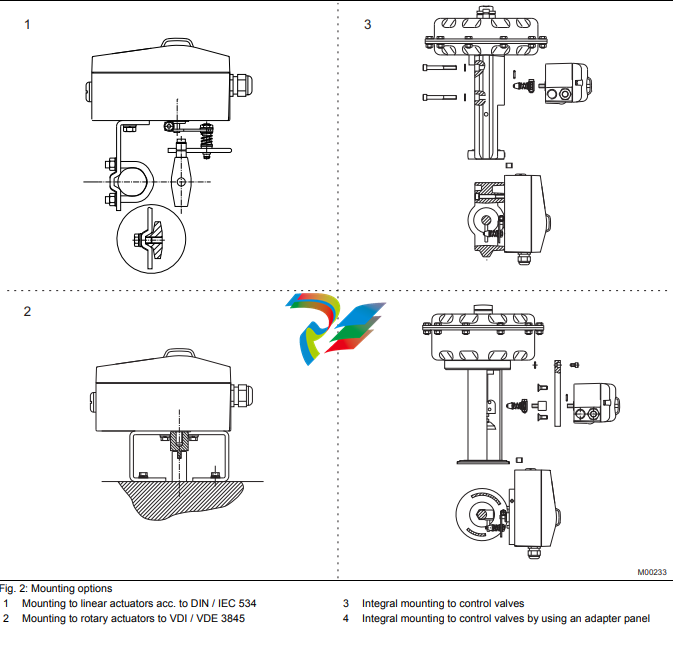

2 Mounting versions Pos: 5.2 /==== Wechsel ein- auf zweispaltig ==== @ 0mod_1130421847171_3101.doc @ 3828 Wechsel ein-auf zweispaltig Pos: 5.3 /Überschriften/1.1/2-spaltig/Genormter Anbau an pneumatische Linearantriebe @ 10mod_1176212852312_3101.doc @ 76956 2.1 To linear actuators in accordance with the standard Pos: 5.4 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Montage/Genormter Anbau an pneumatische Linearantriebe @ 10mod_1176213091968_3101.doc @ 77040 Lateral attachment is in accordance with DIN / IEC 534 (lateral attachment to NAMUR). The required attachment kit is a complete set of attachment material, but does not include the screwed pipe connections and air pipes. Pos: 5.5 /Überschriften/1.1/2-spaltig/Genormter Anbau an pneumatische Schwenkantriebe @ 10mod_1176212899953_3101.doc @ 76977 2.2 To rotary actuators in accordance with the standard Pos: 5.6 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Montage/Genormter Anbau an pneumatische Schwenkantriebe @ 10mod_1176213146937_3101.doc @ 77061 This attachment is designed for mounting according to the standard VDI/VDE 3845. The attachment kit consists of a console with mounting screws for mounting on a rotary actuator. The adapter for coupling the positioner feedback shaft to the actuator shaft has to be ordered separately. Screwed pipe connections and air pipes have to be provided on site. Pos: 5.7 /======= Spaltenumbruch ======== @ 0mod_1132937966324_3101.doc @ 3831 Pos: 5.8 /Überschriften/1.1/2-spaltig/Integrierter Anbau an Regelventile @ 10mod_1176212940421_3101.doc @ 76998 2.3 Integral mounting to control valves Pos: 5.9 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Montage/Integrierter Anbau an Regelventile, TZIDC-1x0 @ 10mod_1176213402234_3101.doc @ 77103 The TZIDC positioner featuring standard pneumatic action is also suitable for integral mounting. The required holes are found at the back of the device. The benefit of this design is that the point for mechanical stroke measurement is protected and that the positioner and actuator are linked internally. No external tubing is required. Pos: 5.10 /Überschriften/1.1/2-spaltig/Besondere antriebsspezifische Anbauversionen @ 10mod_1176212991062_3101.doc @ 77019 2.4 Special actuator-specific mounting Pos: 5.11 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Montage/Besondere antriebsspezifische Anbauversionen @ 10mod_1173186727709_3101.doc @ 71265 In addition to the mounting methods described above, there are special actuator-specific attachments. Please contact us for details.

3 Operation Pos: 7.2 /==== Wechsel ein- auf zweispaltig ==== @ 0mod_1130421847171_3101.doc @ 3828 Wechsel ein-auf zweispaltig Pos: 7.3 /Überschriften/1.1/2-spaltig/Allgemeines @ 10mod_1176213970765_3101.doc @ 77124 A 3.1 General Pos: 7.4 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Betrieb/Allgemeines @ 10mod_1176214294328_3101.doc @ 77292 Microprocessor-based position control in the TZIDC provides for optimal results. The positioner features high-precision control functions and high operational reliability. Due to their elaborate structure and easy accessibility, the device parameters can be quickly adapted to the respective application. The total range of parameters includes: - Operating parameters - Adjustment parameters - Monitoring parameters - Diagnosis parameters - Maintenance parameters Pos: 7.5 /Überschriften/1.1.1/2-spaltig/Betriebsparameter @ 10mod_1176214001500_3101.doc @ 77145 3.1.1 Operating parameters Pos: 7.6 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Betrieb/Betriebsparameter @ 10mod_1176214346265_3101.doc @ 77343 The following operating parameters can be set manually if required: Signal Signal min. 4 mA, max. signal 20 mA (0 ... 100 %) freely selectable for split-range operation min. range 20 % (3.2 mA) recommended range > 50 % (8.0 mA) Action (positioning signal) Increasing: Signal 4 ... 20 mA = position 0 ... 100 % Increasing: Signal 20 ... 4 mA = position 0 ... 100 % Characteristic curve (travel = f {signal}) Linear, equal percentage 1:25 or 1:50 or 25:1 or 50:1 or freely configurable with 20 reference points. Travel limit The positioning travel, i.e. the stroke or angle of rotation, can be reduced as required within the full range of 0 ... 100 %, provided that a minimum value of 20 % is observed. Shut-off function This parameter can be set separately for each end position. When the respective configured limit value is exceeded, the shut-off function causes immediate travel of the actuator until reaching the set end position. When the shut-off value is set to “0”, the position is further controlled, even in the respective end position. Travel time prolongation This function can be used to increase the max. travel time for full travel. This time parameter can be set separately for each direction. Important This function can only be used with the pneumatics with the safety function “fail-safe”. Switching points for the position This parameter allows you to define two position limits for signaling (see option “Module for digital position feedback”). Digital output The alarms generated in the TZIDC positioner can be polled via the digital output as a collective alarm. The desired information can be selected via the operator panel or remotely via the configuration program. The output can be set to “active high” or “active low”, as required. Digital input For the digital input, one of the following safety options can be selected. You may use the operator’s panel or configuration program to select an option. - No function (default) - Move to 0 % position - Move to 100 % position - Hold previous position - disable local configuration - Disable local configuration and operation - Disable any access (no local or remote access via a PC) The selected function is activated once the 24 V DC signal is no longer applied (< 11 V DC). Pos: 7.7 /Überschriften/1.1.1/2-spaltig/Justageparameter @ 10mod_1176214036515_3101.doc @ 77166 3.1.2 Adjustment parameters Pos: 7.8 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Betrieb/Justageparameter @ 10mod_1176214397515_3101.doc @ 77364 The TZIDC positioner has a special function for automatic adjustment of the parameters. Additionally, the control parameters can be set automatically (in adaptive control mode) or manually to optimally adapt them to the process requirements. Tolerance band When reaching the tolerance band the position is considered as corrected. From this point on, the position is further slowly readjusted until the dead band is reached. The factory setting for this parameter is 0.3 %. Dead band (sensitivity) When reaching the dead band, the position is held. The factory setting for this parameter is 0,1 %. Actuator spring action Selection of the sensor shaft rotating sense (looking into the open case), if the valve is moved to the safe position by the actuator spring (actuator is depressurized via Y1/OUT1). For double-acting actuators the actuator spring action corresponds to pressurizing the pneumatic output (OUT2). Display 0 ... 100 % Adjusting the display (0 ... 100 %) according to the direction of action for opening or closing the valve. Pos: 7.9 /Überschriften/1.1.1/2-spaltig/Betriebsüberwachungsparameter @ 10mod_1176214071453_3101.doc @ 77187 3.1.3 Monitoring parameters Pos: 7.10 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Betrieb/Betriebsüberwachungsparameter @ 10mod_1176214447375_3101.doc @ 77385 B Various functions for permanent operational monitoring are implemented in the TZIDC operating program. The following states will be detected and indicated, e.g.: - 4 ... 20 mA signal out of range - position out of the adjusted range - positioning time-out (adjustable time parameter) - position controller inactive - counter limits (settable in the diagnosis phase) exceeded While automatic commissioning is in progress, the current state is continuously indicated on the integrated LCD. During operation, the LCD shows the most important process variables: - current position (in %), - malfunctions, alarms, messages (as code) Access to extended monitoring parameters is possible via HART communication and the DTM.

3.1.4 Diagnosis parameters Pos: 7.13 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Betrieb/Diagnoseparameter @ 10mod_1176214500906_3101.doc @ 77406 The diagnosis parameters of the TZIDC program inform the operator about the operating conditions of the valve. From this information the operator can derive which maintenance works are required, and when. Additionally, limit values can be defined for these parameters. When they are exceeded, an alarm is reported. The following values are e.g. determined: - Number of movements performed by the valve - Total travel The diagnosis parameters and limit values can be called up, set, and reset via HART communication, using the configuration program. Pos: 7.14 /Überschriften/1.1/2-spaltig/Bedienpanel @ 10mod_1176214143953_3101.doc @ 77229 3.2 Operator panel Pos: 7.15 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Betrieb/Bedienpanel TZIDC-1x0 @ 10mod_1176214815500_3101.doc @ 77427 The TZIDC positioner’s operator panel with four pushbuttons allows for - operational monitoring - manual control - configuration - fully automatic commissioning The operator panel is protected by a cover which avoids unauthorized access to the operating elements. Pos: 7.16 /======= Spaltenumbruch ======== @ 0mod_1132937966324_3101.doc @ 3831 Pos: 7.17 /Überschriften/1.1.1/2-spaltig/Ein-Tasten-Inbetriebnahme @ 10mod_1176214193156_3101.doc @ 77250 3.2.1 Single-button commissioning Pos: 7.18 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Betrieb/Ein-Tasten-Inbetriebnahme @ 10mod_1176214842843_3101.doc @ 77448 Commissioning the TZIDC positioner is especially easy. The standard Autoadjust function for automatic adaptation of the device parameters can be started by simply pressing a single front panel button, and without knowing parameterization details. Depending on the selected actuator type (linear or rotary), the displayed zero position is automatically adapted: - for linear actuators counter-clockwise (CTCLOCKW) - for rotary actuators clockwise (CLOCKW). Besides this standard function, a customized “Autoadjust” function is available. The function is launched either via the operator’s panel or HART communication. Pos: 7.19 /Überschriften/1.1.1/2-spaltig/Anzeigen @ 10mod_1176214259859_3101.doc @ 77271 3.2.2 Display Pos: 7.20 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Betrieb/Anzeigen @ 10mod_1176214873937_3101.doc @ 77469 The information indicated by the 2-line LC display is permanently updated and adapted during operation, to inform the operator in an optimal way. During control operation (control with or without adaptation) the following TZIDC data can be called up by pressing the pushbuttons briefly: - Up button: Current setpoint (mA) - Down button: Temperature in device - Up + Down buttons: Current control deviation

4.1 DTM Pos: 9.4 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Kommunikation/DTM @ 10mod_1176215507046_3101.doc @ 77595 The DTM (Device Type Manager) for TZIDC is based on the FDT/DTM technology (FDT 1.2) and can be integrated in a process control system or loaded in a PC with the DSV401 (SMART VISION) program. This allows you to work with the same user interface in the commissioning phase, during operation, and for service tasks for monitoring the device, setting parameters, and uploading data. Communication is based on the HART protocol. It occurs via a local interface connection (LKS) or in frequency-modulated mode using an FSK-modem connected at any chosen point of the 20 mA signal line. Communication has no effect on operation. Newly set parameters are saved in the non-volatile memory directly upon the download into the device, and become active immediately. Pos: 9.5 /Überschriften/1.1/2-spaltig/LKS-Adapter (RS-232 Schnittstellenwandler) @ 10mod_1176215338250_3101.doc @ 77532 4.2 LKS adapter (RS-232 interface converter) Pos: 9.6 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Kommunikation/LKS-Adapter (RS-232 Schnittstellenwandler) @ 10mod_1176215612828_3101.doc @ 77616 You can easily connect your TZIDC positioner to a PC, e.g., in the workshop or in the commissioning phase, by using the positioner’s LKS adapter (LKS = local communication interface). An RS-232 interface converter adapts the signals on the serial PC port to the level of the positioner’s LKS. Pos: 9.7 /Überschriften/1.1/2-spaltig/FSK-Modem @ 10mod_1176215390421_3101.doc @ 77553 4.3 FSK Modem Pos: 9.8 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Kommunikation/FSK-Modem @ 10mod_1176215656328_3101.doc @ 77637 The FSK modem establishes a digital frequency-modulated communication (Frequency Shift Keying) with the TZIDC positioner. Tapping is possible at any chosen point of the 20 mA signal line. We recommend that you use an electrically isolated FSK modem. It is bus-compatible when used with isolating amplifiers. Even connecting explosion-protected field devices is possible, on condition that the FSK modem is run outside the hazardous a

5 Technical data Pos: 11.2 /==== Wechsel ein- auf zweispaltig ==== @ 0mod_1130421847171_3101.doc @ 3828 Wechsel ein-auf zweispaltig Pos: 11.3 /Überschriften/1.1/2-spaltig/Eingang @ 0mod_1139395051468_3101.doc @ 3221 5.1 Input Pos: 11.4 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Technische Daten/Eingang / Stellsignal (Zweileitertechnik) @ 10mod_1176272560140_3101.doc @ 77936 Output signal (two-wire technology) Nominal range 4 ... 20 mA Split range configuration between 20 ... 100 % of the nominal range Max. 25 mA Min. 3.6 mA Starting at 3,8 mA Load voltage at 20 mA 9,7 V Impedance at 20 mA 485 Ω Digital input Control voltage 0 ... 5 V DC logical switching state "0" 11 ... 30 V DC logical switching state "1" Current max. 4 mA Pos: 11.5 /Überschriften/1.1/2-spaltig/Ausgang @ 10mod_1176215873937_3101.doc @ 77658 5.2 Output Pos: 11.6 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Technische Daten/Ausgang / Druckluftausgang @ 10mod_1176272620812_3101.doc @ 77957 Compressed air output Range 0 ... 6 bar (0 ... 90 psi) Air capacity 5.0 kg/h = 3.9 Nm³/h = 2.3 sfcm at 1.4 bar (20 psi) supply pressure 13 kg/h = 10 Nm³/h = 6,0 sfcm at 6 bar (90 psi) supply pressure Output function For single or double-acting actuators, air is vented from actuator or actuator is blocked in case of (electrical) power failure Shut-off values End position 0 % = 0 ... 45 % End position 100 % = 55 ... 100 % Digital output (control circuit to DIN 19234/NAMUR) Supply voltage 5 ... 11 V DC Current > 0.35 mA … < 1.2 mA Switching state logical "0" Current > 2.1 mA Switching state logical "1" Effective direction (configurable) normally logical "0" or logical "1" Pos: 11.7 /Überschriften/1.1/2-spaltig/Stellweg @ 10mod_1176215894234_3101.doc @ 77679 5.3 Travel Pos: 11.8 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Technische Daten/Stellweg / Drehwinkel @ 10mod_1176272774203_3101.doc @ 77978 Rotation angle Used range 25 ... 120 (rotary actuators, optional 270°) 25 ... 60 ° (linear actuators) Travel limit Min. and max. limits, freely configurable between 0 ... 100 % of total travel (min. range > 20 %) Travel time prolongation Range of 0 ... 200 seconds, separately for each direction Dead band time limit Range 0 ... 200 seconds (monitoring parameter for control until the deviation reaches the tolerance band) Pos: 11.9 /======= Spaltenumbruch ======== @ 0mod_1132937966324_3101.doc @ 3831 Pos: 11.10 /Überschriften/1.1/2-spaltig/Luftversorgung @ 10mod_1176215914875_3101.doc @ 77700 5.4 Air supply Pos: 11.11 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/Allgemein/Technische Daten/Luftversorgung TZIDC-1x0 @ 10mod_1176272806906_3101.doc @ 77999 Instrument air free of oil, water and dust acc. to DIN / ISO 8573-1 pollution and oil content according to Class 3 (purity: max. particle size: 5 µm, max. particle density: 5 mg / m3; oil content: max. concentration: 1 mg / m3; pressure dew point: 10 K below operating temperature Supply pressure 1.4 ... 6 bar (20 ... 90 psi) Note: Do not exceed the max. operating pressure of the actuator! Air consumption < 0,03 kg/h / 0,015 scfm (independent of supply pressure) Pos: 11.12 /Überschriften/1.1/2-spaltig/Übertragungsdaten und Einflussgrößen @ 10mod_1176215939812_3101.doc @ 77721 5.5 Transmission data and influences Pos: 11.13 /Technische Daten / Datenblatt/Aktorik/Stellungsregler/TZIDC / TZIDC-200/Technische Daten/Übertragungsdaten und Einflussgrößen @ 10mod_1176272844734_3101.doc @ 78020 Output Y1 Increasing Increasing output signal 0 ... 100 % Increasing pressure at output Decreasing Increasing output signal 0 ... 100 % Decreasing pressure at output Action (positioning signal) Increasing Signal 4 ... 20 mA = actuator position 0 ... 100 % Decreasing Signal 20 ... 4 mA = actuator position 0 ... 100 % Characteristic curve (travel = f {signal}) Linear, equal percentage 1:25 or 1:50 or 25:1 or 50:1 and freely configurable with 20 reference points. Characteristic deviation < 0,5 % Tolerance band 0.3 ... 10 %, adjustable Dead band 0,1 ... 10 %, adjustable Resolution (A/D conversion) > 4000 steps Sample rate 20 ms Influence of ambient temperature < 0.5 % per 10 K Influence of vibration < ± 1 % to 10 g and 80 Hz Seismic requirements Meets requirements of DIN / IEC 68-3-3 Class III for strong and strongest earthquakes. Influence of mounting orientation Not measurable. Meets the requirements of the following directives - EMC Directive 89 / 336 / EWG as of May 1989 - EC Directive for CE conformity marking Communication - HART Protocol 5.1 - Local connector for LKS (local communication interface) adapter - HART communication via 20 mA signal line with (optional) FSK modem

Module for analog position feedback1) Signal range 4 ... 20 mA (configurable split ranges) Supply, 2-wire circuitry 24 V DC (10 ... 30 V DC) 48 V DC (20 ... 48 V DC, no ignition protection) Characteristic curve (configurable) Rising or falling Characteristic deviation < 1 % Important Without a signal from the positioner (e.g., “no energy” or “initializing”) the module sets the output to > 20 mA (alarm level) Module for digital position feedback1) Two switches for digital position feedback (position adjustable within the range of 0 ... 100%, ranges cannot overlap) Current circuits acc. to DIN 19234 / NAMUR Supply voltage 5 ... 11 V DC Signal current < 1.0 mA Switching state logical “0“ Signal current > 2,0 mA Switching state logical “1“ Direction of action normally logical “0“ or logical “1“ (configurable) Module for the emergency shutdown function2) Supply voltage 24 V DC (20 ... 30 V DC) (galvanically isolated from input signal) Safe position is activated when voltage < 5 V Explosion protection see certificate (operating instructions) SIL See “Explosion protection” A separate 24 V DC signal is normally applied to the emergency shutdown module, which connects through the signal from the microprocessor to the I/P module. When the 24 V DC signal is interrupted, the pneumatic module executes the respective safety function, depending on the mechanical construction: The positioner output 1 is depressurized, and the valve is moved to the safe position. In case of a double-acting actuator the second output 2 is additionally pressurized. Important The emergency shutdown module can only be used with pneumatics with the safe position “fail-safe”. The emergency shutdown module works independently of the mother board, i.e. all information from the final control element is available in the supervisory process control system at any time. 1) The module for analog position feedback and the module for digital position feedback plug in separate slots and can be used together. 2) The module for the emergency shutdown function uses the same space as the module for analog feedback and the module for analog or digital feedback and cannot be plugged in and run together with any of them. Digital position feedback with proximity switches Two proximity switches for independent position signaling. Switching points adjustable between 0 … 100 % Current circuits acc. to DIN 19234 / NAMUR Supply voltage 5 ... 11 V DC Signal current < 1.0 mA Switching state logical “0“ Signal current > 2,0 mA Switching state logical “1“ Direction of action (logical state) Position Proximity switch < Lim. 1 > Lim. 1 < Lim. 2 > Lim. 2 SJ2-SN (NC) 0 1 1 0 SJ2-S1N (NO) 1 0 0 1 Important When using SJ2_S1N (NO), the TZIDC positioner may only be used at an ambient temperature range from -25 ... 85 °C (-13 ... 185 °F). Digital position feedback with 24 V microswitches Two microswitches for independent position signaling. Switching points adjustable between 0 … 100 %. Voltage max. 24 V AC / DC Load rating max. 2 A Contact surface 10 µm Gold (AU) Mechanical position indicator Indicator disk in enclosure cover, linked with positioner feedback shaft. Important These options are also available for retrofitting by Service.

.png)

.png)

.png)