REXRTOHRexroth EcoDrive 03 Drive Controllers DKC**.3-040, -100, -200

• Fences and coverings must be strong enough to resist maximum possible momentum.

• Mount the emergency stop switch in the immediate reach of the operator. Verify that the

emergency stop works before startup. Don’t operate the device if the emergency stop is

not working.

• Isolate the drive power connection by means of an emergency stop circuit or use a safety

related starting lockout to prevent unintentional start.

• Make sure that the drives are brought to a safe standstill before accessing or entering the

danger zone.

• Additionally secure vertical axes against falling or dropping after switching off the motor

power by, for example:

– mechanically securing the vertical axes,

– adding an external braking/ arrester/ clamping mechanism or

– ensuring sufficient equilibration of the vertical axes.

• The standard equipment motor brake or an external brake controlled directly by the drive

controller are not sufficient to guarantee personal safety!

• Disconnect electrical power to the equipment using a master switch and secure the switch

against reconnection for:

– maintenance and repair work

– cleaning of equipment

– long periods of discontinued equipment use

• Prevent the operation of high-frequency, remote control and radio equipment near

electronics circuits and supply leads. If the use of such devices cannot be avoided, verify

the system and the installation for possible malfunctions in all possible positions of normal

use before initial startup. If necessary, perform a special electromagnetic compatibility

(EMC) test on the installation.

Magnetic and Electromagnetic Fields

WARNING

Health hazard for persons with heart pacemakers, metal implants and hearing aids in

proximity to electrical equipment!

• Persons with heart pacemakers and metal implants are not permitted to enter following

areas:

– Areas in which electrical equipment and parts are mounted, being operated or

commissioned.

– Areas in which parts of motors with permanent magnets are being stored, repaired or

mounted.

• If it is necessary for somebody with a pacemaker to enter such an area, a doctor must

be consulted prior to doing so. The interference immunity of present or future implanted

heart pacemakers differs greatly, so that no general rules can be given.

• Those with metal implants or metal pieces, as well as with hearing aids must consult a

doctor before they enter the areas described above.

Otherwise health hazards may occur.

Hot Parts

CAUTION

Hot surfaces at motor housings, on drive controllers or chokes! Danger of burns!

• Do not touch surfaces of device housings and chokes in the proximity of heat sources!

Danger of burns!

• Do not touch housing surfaces of motors! Danger of burns!

• According to operating conditions, temperatures can be higher than 60 °C (140 °F)

during or after operation.

• Before accessing motors after having switched them off, let them cool down for a

sufficiently long time. Cooling down can require up to 140 minutes! Roughly estimated,

the time required for cooling down is five times the thermal time constant specified in the

Technical Data.

• Wear safety gloves or do not work at hot surfaces.

• For certain applications, the manufacturer of the end product, machine or installation,

according to the respective safety regulations, has to take measures to avoid injuries

caused by burns in the end application. These measures can be, for example: warnings,

guards (shielding or barrier), technical documentation.

1.2 Appropriate Use

This product may only be used for the applications mentioned in the

reference documentations (see chapter “Reference Documentations”)

and under the described application, ambient and operating conditions.

Identification

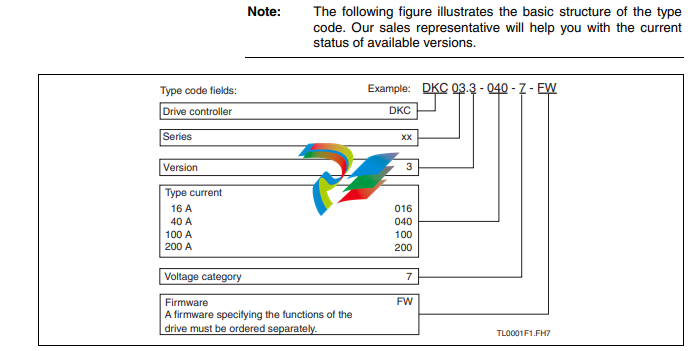

2.1 Type Code

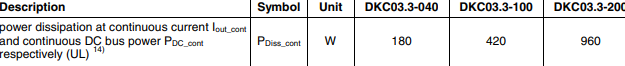

housing dimension; see related dimension sheet also 4) 5) see fig. "Air inlet and outlet of drive controller" 6) observe supply voltage for motor holding brakes 7) find value for control section in project planning manual 8) Suitable for use on a circuit capable of delivering not more than this

SCCR value, 600 V AC or less. The drive series shall be used with

listed AC input line fuses or listed circuit breakers specified in this

documentation.

9) DKC, CZM, BZM: DC bus L+, L-; Mains input L1, L2, L3 10) at PDC_cont 11) class J branch circuit fuse

12) find value for tightening torque in project planning manual, electrical

terminals

13) copper wire; PVC-insulation (conductor temperature 90 °C); Table

13.5.1; Ta ≤ 40 °C

14) plus dissipation of braking resistor

Abb. 3-1: UL ratings and dimensions

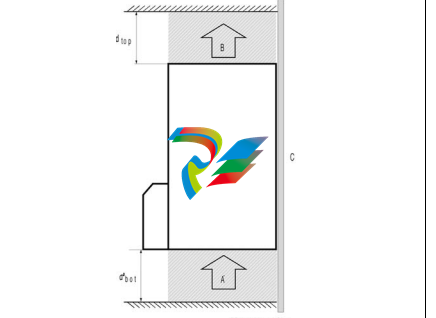

A: air intake

B: air outlet

C: mounting surface in control cabinet

dtop: distance top

dbot: distance bottom

Fig. 3-2: Air intake and air outlet at drive controller

Index

2

24V control voltage supply (+24V and 0V) 5-3

A

Appendix 6-1

Appropriate use 1-4

B

Basic connection of holding brake 5-13

Basic connection of motor power 5-13

Basic connection of motor temperature monitoring 5-13

Bb 5-5

DKC 5-5

BR+, BR- 5-11

C

Connection Choke (DR+, DR-) 5-16

Connection cross section

X1 5-3

X12 5-16

X5 5-7

X6 5-10

Connection Diagram 5-2

Connections 5-1

control cabinet

with multiple-line structure 5-20

Control Cabinet 5-20

Control voltage connections 5-3

Cooling Units 5-20

D

DC Bus Capacitors

discharging 6-1

.png)

.png)

.png)