schneiderFoxboro Evo™ Process Automation System Product Specifications

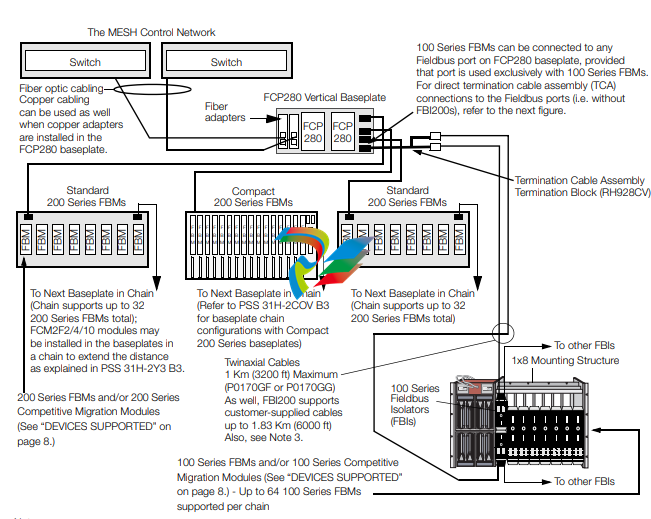

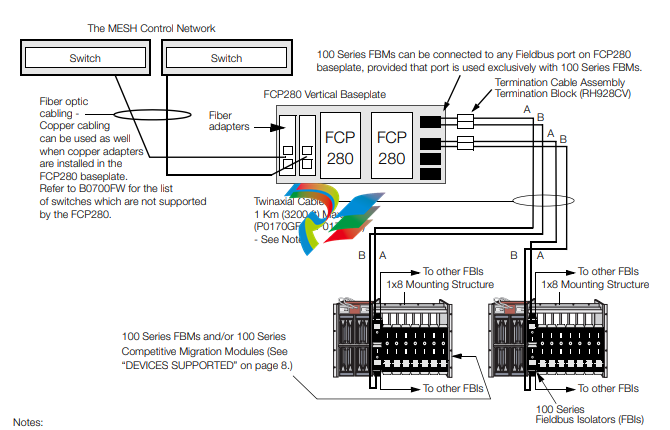

provides a connector for any Fieldbus port on the

FCP280 baseplate, and two Termination Cable

Assembly (TCA) termination blocks for the twinaxial

cabling from the 100 Series FBMs.

The FCP280 can also communicate with serial and

Ethernet devices, such as PLCs, via Field Device

System Integrators. This allows you to connect to

new device interfaces without any changes to the

controller software.

To estimate the FCP280’s processor load, refer to

Field Control Processor 280 (FCP280) Sizing

Guidelines and Excel Workbook (B0700FY)

FIBER AND COPPER NETWORK ADAPTERS

FCP280 modules connect to a pair of fiber or copper

adapters (see Figure 4) which each connect to one

Ethernet switch in The Mesh control network. The

FCP280 baseplate passes inbound traffic from either

of the two switches to both FCP280s, and pass

outbound traffic from the primary FCP280 module to

either switch.

Figure 4. Fiber Optic and Copper Network Adapters

The fiber or copper adapters mount on the FCP280

baseplate as shown in Figure 1 on page 2. They

receive their power from the baseplate.

REMOTE MOUNTING

The FCP280 simplifies the Foxboro Evo Process

Automation System architecture, maintaining control

while only requiring housing (via field enclosures),

host workstations with Foxboro Evo Control Core

Services v9.0 or later, and Ethernet switches for

communication via The Mesh control network

architecture, described in PSS 21H-7C2 B3.

The field-mounted FCP280 is an integral part of the

highly-distributed control network where controllers

are closely aligned to specific process units mounted

in close proximity to their I/O and the actual

equipment being controlled. Coordination between

process units takes place via a fiber optic 100 Mbps

Ethernet network.

The FCP280 and its network adapters are packaged

in a rugged, die cast aluminum housing that does not

require venting due to its efficient design. The

FCP280 and its network adapters are CE certified,

and it can be mounted without expensive special

cabinets to prevent electronic emissions. The

FCP280, network adapters, and baseplate can be

mounted in Class G3 harsh environments.

ENHANCED RELIABILITY (FAULTTOLERANCE)

The unique and patented fault-tolerant operation of

the FCP280 improves reliability relative to legacy

process controllers. The fault-tolerant version of the

FCP280 consists of two modules operating in

parallel, with two Ethernet connections to The Mesh

control network. The two FCP280 modules, married

together as a fault-tolerant pair, provide continuous

operation of the controller in the event of virtually any

hardware failure occurring within one module of the

pair.

Both modules receive and process information

simultaneously, and faults are detected by the

modules themselves. One of the significant methods

of fault detection is comparison of communication

messages at the module external interfaces.

Messages only leave the FCP280 when both

FCP280s agree on the message being sent (bit for

bit match). Upon detection of a fault, self-diagnostics

are run by both modules to determine which module

is defective. The non-defective module then assumes

control without affecting normal system operations.

This fault-tolerant solution has the following major

advantages over controllers that are merely

redundant:

No bad messages are sent to the field or to

applications using controller data because no

message is allowed out of the controller unless

both modules match bit for bit on the message

being sent.

The secondary controller is synchronized with the

primary one, which ensures up to the moment

data in the event of a primary controller failure.

The secondary controller will have latent flaws

detected prior to any switchover because it is

performing exactly the same operations as the

primary controller.

UPGRADE OPTIONS

Multiple options are available for replacing existing

control processors with the FCP280. A fault-tolerant

FCP280 may replace a fault-tolerant FCP270 or

ZCP270. It may import the CP database from the

CP270 it is replacing, for compatibility and minimal

configuration time.

As well the FCP280 provides an increase in

performance and block processing capacity over the

CP270s. When replacing FCP270s, the FCP280

eliminates the need for FEM100 hardware.

For ease of replacement, the fault-tolerant or nonfault-tolerant FCP280 in its baseplate has the same

dimensions as the fault-tolerant or non-fault-tolerant

FCP270 in its baseplate.

Cabling the 100 Series FBMs or Migration products

to an FCP280 baseplate consists of extending the

remote 268 Kbps fieldbus between enclosures. This

is accomplished using termination cable assemblies

(TCAs) and Fieldbus Isolators (FBIs) to provide

connections between primary and extended fieldbus

.png)

.png)

.png)