GE PAC8000 8755-CA-NS EBIM carrier

The PAC8000 8755-CA-NS EBIM carrier is a component in the GE PAC8000 series control system. The controller and I/O module base plates of this series adopt advanced RailBus bus technology, support hot plugging, and are suitable for various industrial control applications. The following are some features of the GE PAC8000 series: Hardware architecture: The base plate adopts RailBus bus technology. The controller base plate can install redundant controllers and power monitoring modules, and supports the MODBUS RTU protocol. Main controller: It adopts a 266MHz 32-bit microprocessor, featuring dual Ethernet and serial communication interfaces, supporting multiple communication protocols, and can be installed in hazardous Zone 2. I/O module: Supports hazardous Zone 1 and Zone 2 application modules, equipped with intrinsically safe safety barriers, featuring channel isolation and LED indication, and supports hot plugging. Software tools: Provide a complete project development environment, supporting functions such as offline simulation, online adjustment, and automatic document generation. Communication function: Integrates multiple communication protocols, such as MODBUS TCP, MODBUS RTU, HART, fieldbus, etc., and supports redundant communication. Reliability: The system is equipped with redundant controllers and power supply configurations to ensure the continuity and safety of critical applications.

The GE PAC8000 8755-CA-NS EBIM carrier is a powerful controller suitable for the field of process control. The following are its advantages: Excellent hardware performance and adaptability to harsh environments It can be installed in explosion-proof Zone 2 and operate within a temperature range of -40 ° C to +70 ° C. It has an ISASP71.04G3 grade corrosion resistance, a humidity adaptability range of 5% to 95%, and can withstand 30g impact and 5g vibration. It is suitable for harsh environments such as wellhead Rtus and gas gathering stations. Advanced bus technology: Utilizing RailBus bus technology, it supports hot-swapping, facilitating maintenance and expansion. Powerful processing capability: Equipped with a 266MHz 32-bit microprocessor, 25M memory, and capable of installing 64 I/O modules, it meets complex control requirements. High-precision I/O module: The resolution of analog input A/D conversion reaches 16 bits, and the output reaches 12 bits. It supports HART protocol and has functions such as loop detection, linearization, and engineering unit conversion. The software is rich in functions.

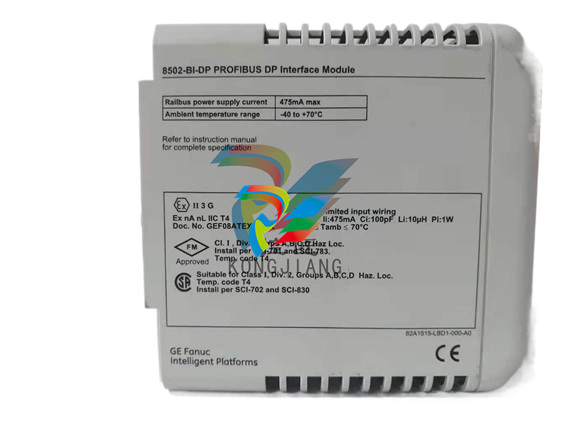

GE PAC8000 8755-CA-NS EBIM is a carrier of a comprehensive process automation solution for process control. The following is the parameter information about this product: Environmental adaptability - Operating temperature: It can operate normally within a temperature range of -40 to 70℃. Anti-corrosion certification: Equipped with G3 anti-corrosion certification, it is suitable for harsh industrial environments. Humidity range: Can withstand a relative humidity of 5% to 95%. Impact and vibration resistance: Capable of withstanding an impact of 30g and a vibration of 5g. Hardware features: IO module support: Supports all series of IO module types, including built-in safety barrier function modules, with a maximum of 32 IO modules supported. Network interface: It provides 10/100Mbps RJ45 interface, 100Mbps multimode optical fiber interface, and USB interface for firmware upgrade. Diagnostic function: It is equipped with channel-level diagnostic function and can monitor the status of IO modules in real time. Hot plugging: Supports hot plugging of IO modules, facilitating maintenance and upgrades. Safety and Certification Safety Certification: Complies with safety certification standards such as CE, UL, ATEX (Zone 2), etc. Power supply and redundant power supply configuration: The power module supports N+1 redundant configuration and adopts a floating design to ensure stable system operation. Software and Configuration Configuration tools: Configuration is carried out using the PAC8000 Workbench software, supporting offline simulation and online adjustment. Control Strategy: Supports process and discrete control strategies, and features powerful SOE capabilities. Communication protocol support: Supports multiple communication protocols such as PROFINET, Modbus TCP, Modbus RTU, Ethernet/IP, etc. Target market application fields: Suitable for harsh working conditions in industries such as oil and gas, petrochemicals, and chemicals. In conclusion, the GE PAC8000 8755-CA-NS EBIM carrier has strong environmental adaptability and flexible hardware configuration, and can meet the requirements of complex industrial automation control.

The usage method of the 8755-CA-NS EBIM (Electronic Bus Interface Module) in the GE PAC8000 series involves multiple steps, including installation, configuration and integration into the control system. The following is a detailed guide based on the search results: Installation environment requirements: Ensure that the installation environment complies with the requirements of the GE PAC8000 series, including temperature, humidity and explosion-proof grade. Physical installation: Install the 8755-CA-NS EBIM module onto the base plate of the control system, ensuring a firm connection between the module and the base plate. Configure power management: Check whether the power supply is stable to ensure that the module can work normally. I/O signal processing: Configure the module to handle input and output signals, including signal type, range and conversion Settings. Modular design: According to the system requirements, other modules are added or removed to achieve flexible configuration of the system. Integrated communication Settings: Configure the communication parameters of the module, such as baud rate, data bits, stop bits, and check bits, to ensure communication compatibility with other devices. Software configuration: Use the configuration tool software packages provided by GE (such as PAC8000 Workbench) for software configuration, including creating projects, defining I/O points, writing control logic and monitoring interfaces, etc. Regular maintenance checks: Inspect the operational status of the module, including power indicator lights, I/O status indicator lights, etc. Troubleshooting: If any abnormal operation of the module is detected, troubleshoot it according to the user manual. Contact technical support if necessary. Precautions: Before performing any operation, make sure to read and understand the user manual and technical specifications of the GE PAC8000 series. Follow all safety guidelines and operating procedures, especially when handling power and signal connections. If you are not familiar with the operation of the control system or module, it is recommended that you receive professional training or seek the help of experienced technicians. Through the above steps, the GE PAC8000 8755-CA-NS EBIM module can be effectively used to realize the signal processing and communication functions in industrial automation and process control applications.

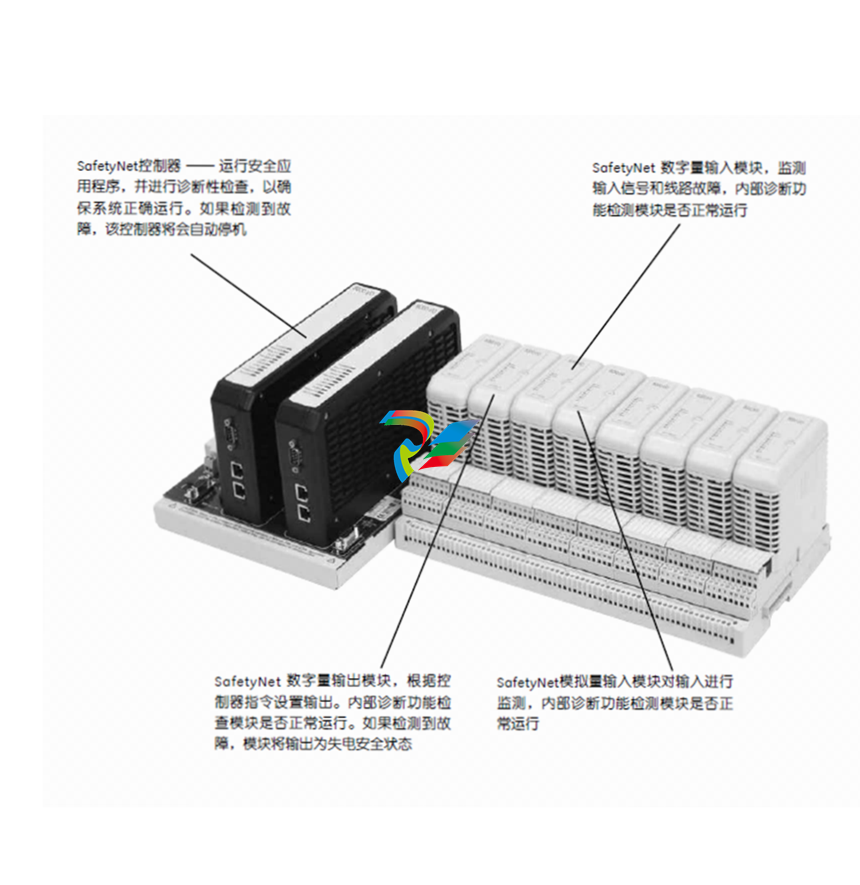

The precautions regarding the 8755-CA-NS EBIM in the GE PAC8000 system are as follows: Hardware installation and configuration environmental adaptability: Ensure that the installation environment meets the equipment requirements, including temperature, humidity, shock resistance, and vibration resistance, etc. Base plate selection: Choose the appropriate base plate based on the on-site signal requirements, and pay attention to the differences between Zone 1 and Zone 2 applications. Power supply configuration: The power module with N+1 redundant configuration is adopted to ensure stable power supply to the system. Software usage and maintenance configuration tools: Use PAC8000 Workbench for project development, and pay attention to the application of offline simulation and online adjustment functions. Document management: Utilize the software's automatic document generation function to ensure the timely update and accuracy of system documents. Security and Diagnostic Security access: Restrict access rights to security-related parameters. Only authorized users can make modifications. Diagnostic function: Utilize the internal diagnostic function of the SafetyNet controller to detect and handle faults in a timely manner. Communication and integrated communication protocols: Ensure that the system supports the required communication protocols, such as MODBUS TCP, MODBUS RTU, HART, etc. System integration: When integrating other systems, pay attention to the compatibility and communication stability between systems. By following the above precautions, the correct use of 8755-CA-NS EBIM in the GE PAC8000 system can be ensured, guaranteeing the stable operation and security of the system. The content is generated by an AI large model and is for reference and collection only

.png)

.png)

.png)