schneiderIGP10, IGP20 Intelligent Gauge Pressure Transmitters IAP10 Intelligent Absolute Pressure Transmitter

• IGP10 for compact light weight and direct-to-process

mounting (bracket optionally available)

• IGP20, bracket mounted, for lower ranges, more

material options, and vacuum service

• Field-proven silicon strain gauge technology

• Corrosion-resistant epoxy finish

• Accuracy to ± 0.07 % of span

• Ambient temperature effects to ± 0.2 % URL

per 55 °C (100 °F) change

• Intelligent FOXCOM & HART / 4 to 20 mA version

or economical 4 to 20 mA version

• LCD Indicator / Pushbutton Configurator

to set zero, span, display units, etc.

Optional on Digital / 4 to 20 mA version,

Standard on 4 to 20 mA version

These Intelligent, two-wire transmitters provide precise, reliable, measurement of gauge or absolute

pressure, and transmit a 4 to 20 mA output signal

with a superimposed HART/ FOXCOM digital signal for remote configuration and monitoring.

Accuracy (Includes Linearity, Hystersis, and

Repeatability)

Electronics

Version

Configured

Output Signal

Accuracy in %

of Calib. Span

-D & -T Digital

4 to 20 mA

± 0.07

± 0.1

-I 4 to 20 mA ± 0.2

Model Codes IGP10

Ambient Temperature Effect

Total effect for a 55 °C (100 °F) change within Normal Operating Conditions limit is:

Electronics -D, -T: ± 0.2 % of URL

Electronics -I: ± (0.2 % of URL + 0.1 % of span)

For complete specifications, refer to Product Specification

Sheet PSS 2A-1C13 B

Intelligent Direct Connected Gauge Pressure Transmitter IGP10

Electronics Versions and Output Signal

Intelligent; Digital FoxCom and/or 4 to 20 mA dc, Configurable . . . . . . . . . . . . . . -D

Intelligent; Digital HART and 4 to 20 mA . . . . . . . . . . . . . . . . . . . . . . . . . -T

4 to 20 mA Analog Output, Explosionproof and Intrinsically Safe . . . . . . . . . . . . . -I

Structure Code - Process Connection, Sensor, and Fill Fluid

Process Connection Mat’l Sensor Fill Fluid

316L ss Co-Ni-Cr Silicone. . . . . . . . . . . . . . . . . . . . . . . . 20

316L ss Co-Ni-Cr Fluorinert . . . . . . . . . . . . . . . . . . . . . . . 21

316L ss 316L ss Silicone . . . . . . . . . . . . . . . . . . . . . . . 22

316L ss 316L ss Fluorinert. . . . . . . . . . . . . . . . . . . . . . . 23

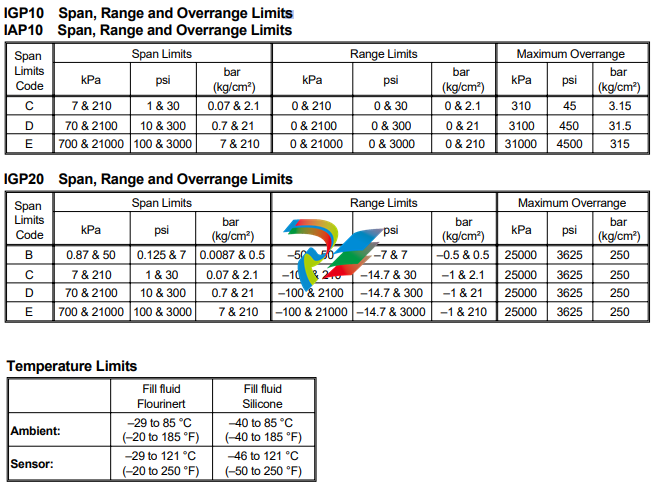

Span Limits - Absolute or Gauge Pressure Units, as Applicable

MPa psi bar or kg/cm²

0.007 and 0.21 1 and 30 0.07 and 2.1..............................C

0.07 and 2.1 10 and 300 0.7 and 21 ..............................D

0.7 and 21 100 and 3000 7 and 210 .............................E

Conduit Connection

1/2 NPT Conduit Connection, Both Sides ...................................1

PG 13.5 Conduit Connection, Both Sides (available only with Electrical Safety CodesE&N .........2

Electrical Safety (See Electrical Safety Specifications Section)

CENELEC Certified Intrinsically Safe, ia ......................................E

CSA Certified ....................................................N

EUROPEAN Ex, N, IIC. Nonsparking ........................................C

FM Approved ....................................................F

SAA Certified, EEx, d, IIC ..............................................A

Options

Mounting Bracket Set

Painted Steel Bracket with Plated Steel Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M1

Stainless Steel Bracket with Stainless Steel Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M2

Digital Indicator with Pushbuttons (standard equipment on IGP10-I)

Digital Indicator, Pushbuttons, and Window Cover (for Electr VersionD&T only) . . . . . . . . . . . . . . . . . . . . . -L1

Vent Screw and Block & Bleed Valve

Vent Screw in Process Connection for IGP10/IAP10; or in High Side Process Cover for IGP20. . . . . . . . . . . . . . . V1

Block and Bleed Valve, Carbon Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V2

Block and Bleed Valve, 316 ss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V3

Block and Bleed Valve, 316 ss Body w/Monel Trim (NACE Approved) . . . . . . . . . . . . . . . . . . . . . . . . . . . V4

Conduit Thread Adapters

Hawke-Type 1/2 NPT Cable Gland for use with Conduit Connection Code “1” . . . . . . . . . . . . . . . . . . . . . . . A1

Plastic PG 13.5 Connector for use with Conduit Connection Code “2” (available only with Electrical Safety Codes E & N) . A2

M20 Connector for use with Conduit Connection Code “1” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3

Electronics Housing Features

External Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Z1

Custody Transfer Lock and Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Z2

External Zero Adjustment and Custody Transfer Lock and Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Z3

Factory Configuration

Digital Output (4 to 20 mA Default if not selected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C1

Full Factory Configuration (Requires Configuration Form to be filled out) . . . . . . . . . . . . . . . . . . . . . . . . . . C2

Miscellaneous Optional Selections

G 1/2 B Manometer Process Connection (Not Available with Option “-V1”) .........................G

.png)

.png)

.png)