EMERSONM-series Virtual I/O Module 2

Non-intrusive DeltaV™ I/O simulation

Powerful integration solution

Easy to use

Modular, flexible packaging

Introduction

The DeltaV M-series Virtual I/O Module 2 (VIM2)

provides nonintrusive simulation of the DeltaV Mseries I/O Cards and digital bus field devices for

process simulation when used with MYNAH

Technologies’ MiMiC Simulation Software. DeltaV

Control strategies and system configurations can be

fully tested with this powerful simulation interface.

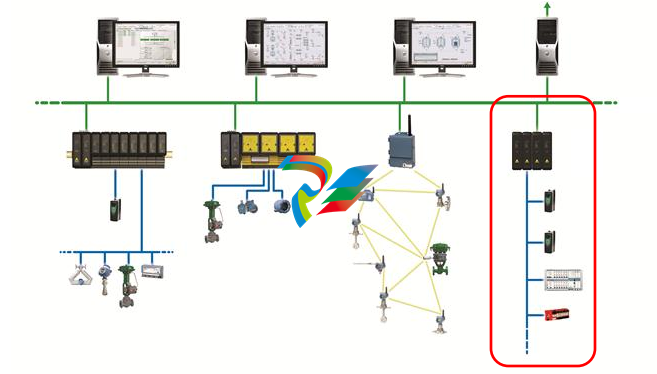

The VIM2 also provides an interface to Ethernet I/O

networks and devices that use the Modbus TCP/IP

or Ethernet/IP protocol drivers. DeltaV M-series

controllers can read and write signals from plant

floor devices connected to Ethernet I/O networks

such as PLC’s, Motor Control Centers, and Weigh

Scales.

Benefits

Non-Intrusive DeltaV I/O simulation. Use the VIM2

in conjunction with the MYNAH Technologies’ MiMiC

Simulation Software to simulate your DeltaV M-Series

I/O and digital bus field devices.

Supports DeltaV I/O modules. Provides completely

non-intrusive simulation of all DeltaV M-series I/O

Modules. Supports autosensing of I/O and accurate

testing of controller loading. DeltaV configuration can

be fully tested without modifying the control

strategies.

Digital bus support. Provides simulation of all

DeltaV Digital Busses and Foundation Fieldbus

function blocks. Supports Foundation Fieldbus control

in the field configuration testing.

Powerful simulation solution. Provides full

simulation of up to 64 DeltaV I/O modules per

controller. Simulation execution is fast and efficient;

the DeltaV controller thinks it’s talking with real IO.

Powerful integration solution. Use the VIM2 in

conjunction with the MYNAH Ethernet I/O drivers to

integrate your DeltaV system with your Ethernet I/O device

networks.

Large device capacity. Each VIM emulates four

DeltaV Serial Cards and support up to 128 Serial

Card Datasets of information from 32 network devices

in simplex installations and 16 devices in redundant

installations. Communication over the Ethernet I/O

device network is fast and efficient.

Flexible networking. User configurable IP

addressing allows the VIM2 to be used in almost any

plant environment regardless of networking scheme.

The VIM2 and the Ethernet I/O devices must be on

the same IP subnet to communicate.

1:1 Redundancy. Redundancy can be added to any

Ethernet I/O system by adding a second VIM2 and

configuring the two cards as a redundant pair. The

VIM2 appears as four redundant DeltaV Serial Card

pairs. Automatic switchover of primary to standby

cards is handled like the DeltaV Serial Card. The

operator is given clear notification of a switchover at

the operator display. Manual switchover can be

controlled in DeltaV Diagnostics.

Easy to use. The VIM2 is easy to use and well

integrated into the DeltaV system. Specific ease of use

features include:

Automatic updates. Simulation I/O driver updates for

the VIM2 are included with the MiMiC software

releases. Updates are quick and easy over the

simulation network.

Seamless Ethernet I/O integration. When used with

the MYNAH Ethernet I/O drivers, the VIM2 is seen by

the DeltaV M-series controller as four DeltaV Serial

Cards. Commissioned VIM2s are auto-sensed by the

DeltaV controller as DeltaV Serial Cards.

Configured in DeltaV Explorer. Serial dataset

configuration used for Ethernet I/O integration is done

in the DeltaV Explorer in the same manner as a

DeltaV Serial Card. Ethernet I/O signals can be used

in DeltaV Control Modules, displayed on DeltaV

Operate graphics and stored in the DeltaV

Continuous Historian.

Intuitive setup. The VIMNet Explorer application

provides plug-n-play capability making setup of the

VIM2 easy and intuitive. Graphical, drag-n-drop,

functionality makes setting up multiple VIM2s almost

effortless. VIMNet Explorer is integrated with DeltaV

Explorer to make setup of the VIM2 easy and intuitive.

Modular, flexible packaging. The VIM2 mounts in the

same manner as the DeltaV controller. It mounts in the

controller slot of a DeltaV 2-wide horizontal or 4-wide

vertical carrier and uses a standard DeltaV Power Supply.

The advanced design of the VIM2 will provide years of

uninterrupted use

Product Description

The VIM2 may be used for either DeltaV I/O simulation or

Ethernet I/O device integration. The VIM2 mounts on a 2-

wide horizontal or 4-wide vertical carrier on the left-handside of the DeltaV controller. A dedicated DeltaV power

supply is required.

IO Simulation When used with MYNAH’s MiMiC

Simulation Software, the VIM2 supports I/O simulation all

DeltaV M-series I/O cards including classic IO, Foundation

Fieldbus, ProfibusDP, DeviceNet, ASi-bus and Serial.

MiMiC Simulation Software provide dynamic simulation for

DeltaV system software acceptance testing and operator

training. The MiMiC software works by simulating the

DeltaV I/O. It also simulates field devices using

Foundation Fieldbus, ProfibusDP, DeviceNet and AS-i

buses. In order for MiMiC to do this, the real I/O cards are

disconnected from the control system. The MiMiC driver

writes to the I/O subsystem of the DeltaV controller.

Process models in MiMiC simulate realistic process

reactions to control system output signals.

Each process controller being simulated uses one MiMiC

Dataset. A MiMiC server can have up to 32 datasets or

ports. Each dataset can support up to 4000 MiMiC

simulation tags.

The I/O simulation driver is provided with the VIM2

hardware, pre-loaded in the VIM2. The MiMiC Simulation

Software must be purchased separately from MYNAH

Technologies. Technical support for the MiMiC Simulation

Software and I/O simulation driver is provided by MYNAH

Technologies.

Ethernet I/O Integration When used with the MYNAH

Ethernet I/O drivers, the VIM2 can communicate with

high-speed Ethernet networks over Modbus TCP or

Ethernet/IP. When the VIM2 is configured with the

appropriate Ethernet I/O driver, the DeltaV Controller autosenses a commissioned VIM2 as four DeltaV Serial Cards.

In simplex installations these cards will be sensed in

slots 57-60 or 61-64.

In redundant installations the redundant pairs will be

sensed in slots 57 to 64.

Configuration of the I/O signals from the commissioned

VIM2 is done in the DeltaV Explorer in the same manner

as a DeltaV Serial Card.

VIMNet Explorer. The VIMNet Explorer utility allows the

user to commission the VIM2, setup primary and

redundant VIM2s, and the Ethernet I/O network. The user

is able to specify the IP address, Subnet Mask, and

Gateway of each VIM2 and set the node address and

names of each Ethernet I/O device that is used by the

VIM2. The VIMNet Explorer is also used to flash upgrade

a VIM from one version of a driver to another or to replace

an existing driver type with another. Only one Ethernet I/O

driver may be loaded in the VIM2 at one time.

The VIMNet Explorer application must run on a

workstation that has network connectivity to the Ethernet

I/O network. This may be a DeltaV workstation with the 3rd

network interface card (NIC) connected to the Ethernet I/O

network or may be a non-DeltaV workstation. The VIMNet

Explorer runs on the MS Windows XP or Windows 7

operating system and has an intuitive, graphical user

interface. Connection to the VIM2 is done through the RJ45 Ethernet Connection on the bottom of the VIM2.

The VIMNet Explorer software installation file for the VIM2

is available on a DeltaV v12 and later workstation and on

the DeltaV v12 and later software installation DVD. The

VIMNet Explorer software installation file is also provided

with the purchase of a MYNAH Ethernet I/O driver.

VIM Redundancy. Two VIM2s can be setup as a

redundant pair for installations that require backup

Ethernet I/O networks. Each VIM2 will be installed on its

own 2-wide carrier, with its own power supply to the left of

the DeltaV Controller.

The active and standby VIM2s monitor each other with a

continuous status command using the redundancy link

cable supplied with each redundant pair. The active VIM2

communicates over the network to the Industrial Ethernet

device and the standby sends an intermittent signal to the

device to maintain communication integrity.

The Ethernet I/O drivers are not provided with the VIM2

hardware; they must be purchased separately from

MYNAH Technologies. Technical support for the Ethernet

I/O drivers is provided by MYNAH Technologies.

Supported Industrial Ethernet

Protocols

Modbus TCP/IP The VIM2 with the Modbus TCP/IP

Master Driver supports the following Modbus

communications protocol function codes to read and write

values to and from a Modbus slave device, as specified by

the Modbus Application Protocol Specification from

Modbus-IDA.org.

The VIM2 Modbus TCP/IP Driver supports the following

Modbus function codes:

Code 1 - Read Coil Status

Code 2 - Read Input Status

Code 3 - Read Holding Registers

Code 4 - Read Input Registers

Code 5 - Force Single Coil

Code 6 - Preset Single Register

Code 8 - Diagnostic Loop Back Test

Code 15 - Force Multiple Coils

Code 16 - Preset Multiple Registers

The VIM2 can function as both a Modbus TCP/IP master

and slave simultaneously. Master or slave mode is set at

the virtual port level. In master-only mode, this driver can

communicate with a maximum of 32 slave devices.

Systems that use both master and slave mode can

communicate with a maximum of 16 slaves and 16

masters at the same time. The master and slave capability

is available in simplex implementations only. In redundant

applications, only master mode is supported.

Ethernet/IP The VIM2 with the Ethernet/IP Scanner Driver

provides the following compatible functions using the

Control and Information Protocol (CIP) as defined in the

Ethernet/IP Specification from Open DeviceNet Vendor

Association and ControlNet International.

The VIM2 Ethernet/IP Scanner Class Driver provides:

Ethernet/IP Scanner Class (originator)

functionality

UCMM (unconnected) messaging client and

server Class 3 (connected) messaging client and

server, including encapsulated DF1 message

Class 1 (I/O) connection client and server

DeltaV Licensing Guidelines

DeltaV Software Licensing Requirements (DST count) will

be impacted by DeltaV Module configuration use of VIM2

registers in the same way as Serial Card registers. The

following guidelines can be applied:

A DeltaV Serial Card data set can contain up to 100

values (a value can be any Boolean, 8-bit or 16-bit

number), and up to16 data sets are supported by

each of the 2 ports on the serial card. If the data set

registers are configured as floating point or 32-bit

values, then the maximum value is 50. However, the

serial device, in general, limits the total capacity of the

interface.

Each data set counts as one DST as long as a single

module references all values in the data set. If

multiple modules reference values in a data set, then

the DST count for the data set is equal to the number

of modules referencing the data set.

Values used in modules containing control function

blocks will be counted as Control DSTs.

.png)

.png)

.png)