MOVIDRIVE® MDX60B / 61B Operating Instructions

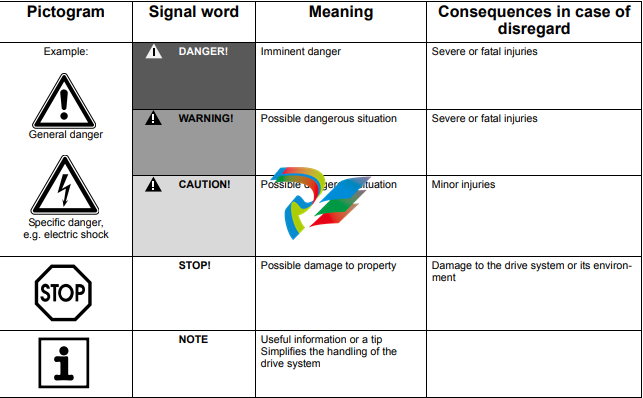

Structure of the Safety Notes

The safety notes in these operating instructions are designed as follows:

Pictogram SIGNAL WORD!

Type and source of danger.

Possible consequence(s) if the safety notes are disregarded.

• Measure(s) to prevent the danger

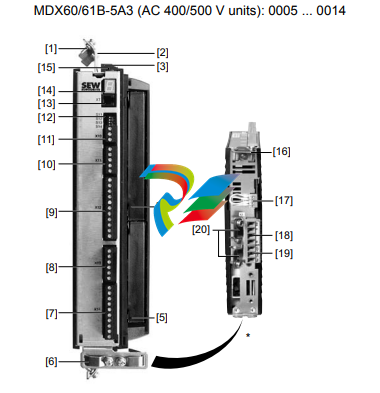

[1] Power shield clamp for mains connection and connection for DC link connection

[2] X4: Connection for DC link connection UZ– / UZ+ and PE connection, separable

[3] X1: Power supply connection L1, L2, L3 and PE connection, separable

[4] Only with MDX61B: Fieldbus slot

[5] Only with MDX61B: Encoder slot

[6] Electronics shield clamp MDX61B size 0

[7] X10: Electronics terminal strip for binary outputs and TF/TH input

[8] X16: Electronics terminal strip for binary inputs and outputs

[9] X13: Electronics terminal strip for binary inputs and RS-485 interface

[10] X11: Electronics terminal strip for setpoint input AI1 and 10 V reference voltage

[11] X12: Electronics terminal strip for system bus (SBus)

[12] DIP switches S11 ... S14

[13] XT: Slot for DBG60B keypad or UWS21B serial interface

[14] 7-segment display

[15] Memory card

[16] Electronics shield clamp MDX60B size 0

[17] X17: Electronics terminal strip for safety contacts for safe stop

[18] X2: Motor connection U, V, W and PE connection, separable

[19] X3: Braking resistor connection +R / –R and PE connection, separable

[20] Power shield clamp for motor connection and braking resistor connection

Exclusion of liability:

You must comply with the information contained in these operating instructions

MDX61B-5A3 (AC 400/500 V units): 0015 ... 0040

MDX61B-2A3 (AC 230 V units): 0015 ... 0037

to ensure safe operation of the MOVIDRIVE® MDX60B/61B drive inverters and to

achieve the specified product characteristics and performance requirements.

SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions.

In such cases, any liability for defects is excluded.

Safety Notes

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must make sure that the basic safety notes are read

and observed. Make sure that persons responsible for the plant and its operation, as

well as persons who work independently on the unit, have read through the operating

instructions carefully and understood them. If you are unclear about any of the information in this documentation, or if you require further information, please contact SEW-EURODRIVE.

2.1 General information

Never install damaged products or take them into operation. Submit a complaint to the

shipping company immediately in the event of damage.

During operation, drive inverters can have live, bare and movable or rotating parts as

well as hot surfaces, depending on their enclosure.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to machinery.

Consult the documentation for additional information.

2.2 Target group

Only qualified electricians are authorized to install, startup, troubleshoot or service the

units (observe IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and IEC 60664 or

DIN VDE 0110 as well as national accident prevention guidelines).

Qualified personnel in the context of these basic safety notes are: All persons familiar

with installation, assembly, startup and operation of the product who possess the necessary qualifications.

All work related to transport, storage, operation and disposal must be carried out only

by personnel who have been trained and instructed accordingly.

2.3 Designated use

Drive inverters are components intended for installation in electrical systems or machines.

In case of installation in machines, startup of the drive inverters (i.e. start of designated

operation) is prohibited until it is determined that the machine meets the requirements

stipulated in the EC Directive 98 37 EC (machine guideline); observe EN 60204.

Startup (i.e. start of designated operation) is only permitted with adherence to EMC

(89/336/EEC) guideline.

The drive inverters meet the requirements stipulated in low voltage guideline

73/23/EEC. The harmonized standards of the EN 61800-5-1/DIN VDE T105 series in

connection with EN 60439-1/VDE 0660 part 500 and EN 60146/VDE 0558 are applied

to these drive inverters.

Technical data and information on the connection requirements are given on the nameplate and in the documentation; they have to be observed under all circumstances.

Safety functions The MOVIDRIVE® MDX60B/61B drive inverters may not perform safety functions without higher-level safety systems. Use higher-level safety systems to ensure protection of

equipment and personnel.

For safety applications, refer to the information in the following publications:

• Safe Disconnection for MOVIDRIVE® MDX60B/61B – Conditions

• Safe Disconnection for MOVIDRIVE® MDX60B/61B – Applications

2.4 Transportation, putting into storage

Observe the notes on transportation, storage and proper handling. Observe the climatic

conditions as stated in the section "General technical data."

2.5 Installation

Installation and cooling of the devices must take place according to the guidelines listed

in the corresponding documentation.

Protect the drive inverters from excessive strain. Especially during transportation and

handling, do not allow the components to be deformed or insulation spaces altered.

Avoid contact with electronic components and contacts.

Drive inverters contain components that can be damaged by electrostatic energy and

improper handling. Prevent mechanical damage or destruction of electric components

(may pose health risk!)

The following applications are prohibited unless measures are expressly taken to make

them possible:

• Use in potentially explosive atmospheres

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

• Use in non-stationary applications that are subject to mechanical vibration and shock

loads in excess of the requirements in EN 61800-5-1.

2.6 Electrical connection

Observe the applicable national accident prevention guidelines when working on live

drive inverters (e.g. BGV A3).

Perform electrical installation according to the pertinent regulations (e.g. line cross sections, fusing, protective conductor connection). For any additional information, refer to

the applicable documentation.

You will find notes on EMC-compliant installation, such as shielding, grounding, arrangement of filters and routing of lines, in the documentation of the drive inverters. Always observe these notes even with drive inverters bearing the CE marking. The manufacturer of the system or machine is responsible for maintaining the limits established

by the EMC legislation.

Preventive measures and protection devices must correspond to the regulations in force

(e.g. EN 60204 or EN 61800-5-1).

Required preventive measures: Ground the unit.

2.7 Safe disconnection

The unit meets all requirements for safe disconnection of power and electronic connections in accordance with EN 61800-5-1. All connected circuits must also satisfy the requirements for safe disconnection.

Operation

Systems with integrated drive inverters must be equipped with additional monitoring and

protection devices, if necessary, according to the applicable safety guidelines, such as

the law governing technical equipment, accident prevention regulations, etc. Changes

to the drive inverter using the operating software are permitted.

Do not touch live components or power connections immediately after disconnecting the

drive inverters from the supply voltage because there may still be some charged capacitors. Note the respective reference plates on the drive inverter.

Keep all covers and doors closed during operation.

The fact that the status LED and other display elements are no longer illuminated does

not indicate that the unit has been disconnected from the power supply and no longer

carries any voltage.

Mechanical blocking or internal safety functions of the unit can cause a motor standstill.

Removing the cause of the problem or performing a reset can result in the drive re-starting on its own. If, for safety reasons, this is not permitted for the driven machine, disconnect the unit from the mains before correcting the fault.

Index of Changes

3.1 Changes compared to the previous version

The following section lists the changes made to the individual sections from edition

01/2005, publication number 11300310 (EN).

Important notes • The section "Important Notes" has been completely revised.

Safety notes • The section "Safety Notes" has been completely revised.

Unit design • The illustrations for unit sizes 0, 1 and 2 have been updated.

• The option "Interface adapter DWE11B/DWE12B" has been included.

Installation • The following subsections have been included in this section:

– "DWE11B/DWE12B interface adapter"

– "UWS21B interface adapter"

• The following parts have been revised in the "Installation instructions for the basic

unit" subsection:

– Section "Tightening torques"

– Section "Fuses and earth-leakage circuit breakers"

– Section "PE input connection"

– Section "IT systems"

– Section "Connecting braking resistors"

– Section "Installing braking resistors BW.../BW...-T/BW...-P"

• All wiring diagrams (power section, braking resistors, electronic terminals) have been

revised.

• The subsection "Assignment of braking resistors, chokes and filters" have been

completely revised.

• In the subsection "Option combinations for MDX61B," the combinations of the

options cards for MDX61B have been updated.

Startup • Startup for an HTL motor encoder has been included.

• Missing parameters have been added to the subsection "Complete parameter list".

Operation and

service

• The subsections "Memory card" and "Error messages and list of faults" have been

completely revised.

• The subsection "Extended storage" has been included.

Technical data

and dimension

drawings

• The section has been completely revised.

Scope of delivery • Connector housing for all signal terminals (X10 ... X17), connected

• Connector housing for the power terminals (X1 ... X4), connected

• Pluggable memory card, connected

Size 0 • 1 set of shield clamps for power cable and signal cable, not installed. The set of

shield clamps comprises:

– 2 shield clamps for power cable (2 contact clips each)

– 1 shield clamp for signal cable (1 contact clip) for MDX60B

– 1 shield clamp for signal cable (2 contact clips) for MDX61B

– 6 contact clips

– 6 screws for attaching the contact clips

– 3 screws for attaching the contact clips to the unit

Sizes 1-6 • 1 set of shield clamps for signal cable, not installed. The set of shield clamps comprises:

– 1 shield clamp for signal cable (1 contact clip)

– 2 contact clips

– 2 screws for attaching the contact clips

– 1 screw for attaching the shield clamp to the unit

• Only for size 6: Carrying bar and 2 split pins

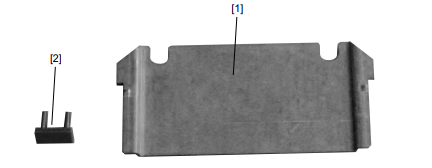

Size 2S • Accessories set, not installed. The accessories set (→ Following illustration) comprises:

– 2 mounting feet [1] to be plugged into the heat sink

– 2 touch guards [2] to be fastened to terminals X4: -Uz/+Uz and X3:-R(8)/+R(9).

Once the touch guards [2] have been installed, the enclosure is IP20. Otherwise

it is IP10 (→ Section "Touch guards").

Optional scope of delivery

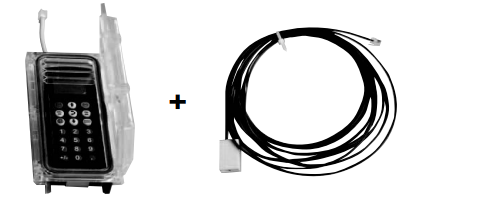

All sizes • Option DBM60B: Door installation for separate mounting of the DBG60B keypad

(e.g. in the control cabinet).

Part number 824,853 2.

The DBM60B option consists of the housing with enclosure IP65 and a 5 m extension cable (→ Following illustration). Das Bediengerät DBG60B ist in dieser Option

nicht enthalten und muss separat bestellt werden.

• Option DKG60B: 5 m Verlängerungskabel für Bediengerät DBG60B.

Part number 817 583 7.

5 m extension cables are available for mounting the keypad separately in customer

housing (→ Following illustration).

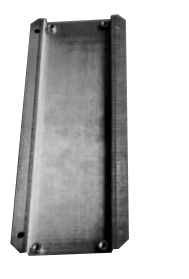

Size 2 S • DMP11B mounting panel (→ following figure), not installed.

Part number 818 398 8.

If a MOVIDRIVE® MD_60A size 2 unit is to be replaced by MOVIDRIVE® MDX61B

size 2S, the MDX61B size 2S can be fitted on the existing mounting plate with the

DMP11B mounting panel. New retaining holes do not have to be drilled.

54588AXX

DMP11B

Connector adapter

for replacing

MOVIDRIVE® A

with

MOVIDRIVE® B

The following adapters are available for rapid replacement of a MOVIDRIVE® A unit with

a MOVIDRIVE® B unit.

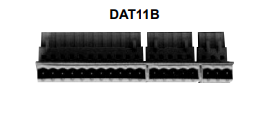

• DAT11B: Terminal adapter, part number 824 671 8

X10 can be rearranged directly when using MOVIDRIVE® MDF, MDV or MDS. Three

plugs have to be rewired. You can avoid such rewiring work by using the DAT11B

terminal adapter. Using this adapter will prevent incorrect connection and save time.

The terminal adapter is required for terminals X11 (analog input), X12 (SBus) and

X13 (binary inputs).

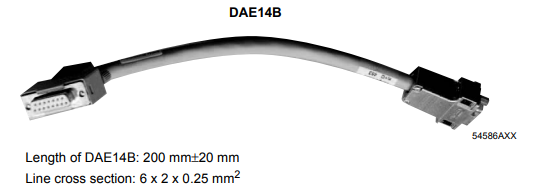

• DAE14B: Encoder adapter X14, part number 817 630 2

If a synchronous encoder is operated at X14 on MOVIDRIVE® MDV, MDS, MCV or

MCS, connection takes place via a 9-pin connector. Since the DEH11B and DER11B

options for MOVIDRIVE® MDX61B come equipped with a 15-pin plug, you will either

have to rework the encoder cable or use the encoder adapter. The encoder adapter

can be plugged directly between the existing encoder cable with 9-pin socket and the

15-pin connector on DEH11B/DER11B. This step makes for fail-safe and fast connection of existing drives

• DWE11B: Interface adapter (adapter cable), part number 188 187 6

The interface adapter DWE11B (HTL→TTL) in the form of an adapter cable is used

to connect single-ended HTL encoders to the HIPERFACE®encoder card

DEH11B. Only the A, B and C tracks are connected. The interface adapter is suitable

for all HTL encoders that were operated on MOVIDRIVE® A, MDV and MCV and can

be connected without any rewiring effort

[1] X1: Power supply connection 1/L1, 2/L2, 3/L3, separable

[2] X4: Connection for DC link connection –UZ +UZ, separable

[3] Fieldbus slot

[4] Expansion slot

[5] Encoder slot

[6] X3: Braking resistor connection 8/+R, 9/–R and PE connection, separable

[7] Electronics shield clamp and PE connection

[8] X2: Motor connection 4/U, 5/V, 6/W and PE connection, separable

[9] X17: Electronics terminal strip for safety contacts for safe stop

[10] X10: Electronics terminal strip for binary outputs and TF/TH input

[11] X16: Electronics terminal strip for binary inputs and outputs

[12] X13: Electronics terminal strip for binary inputs and RS485 interface

[13] X11: Electronics terminal strip for setpoint input AI1 and 10 V reference voltage

[14] X12: Electronics terminal strip for system bus (SBus)

[15] DIP switches S11 ... S14

[16] XT: Slot for DBG60B keypad or UWS21B serial interface

[17] 7-segment display

[18] Memory card

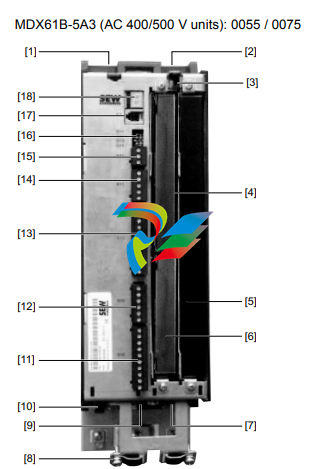

[1] X1: Power supply connection 1/L1, 2/L2, 3/L3

[2] X4: Connection for DC link connection –UZ +UZ and PE connection

[3] Memory card

[4] Fieldbus slot

[5] Expansion slot

[6] Encoder slot

[7] X3: Braking resistor connection 8/+R, 9/–R and PE connection

[8] Electronics shield clamp and PE connection

[9] X2: Motor connection 4/U, 5/V, 6/W

[10] X17: Electronics terminal strip for safety contacts for safe stop

[11] X10: Electronics terminal strip for binary outputs and TF/TH input

[12] X16: Electronics terminal strip for binary inputs and outputs

[13] X13: Electronics terminal strip for binary inputs and RS485 interface

[14] X11: Electronics terminal strip for setpoint input AI1 and 10 V reference voltage

[15] X12: Electronics terminal strip for system bus (SBus)

[16] DIP switches S11 ... S14

[17] XT: Slot for DBG60B keypad or UWS21B serial interface

[18] 7-segment display

.png)

.png)

.png)