MOVIDRIVE® MDX60B / 61B Operating Instructions

Structure of the Safety Notes

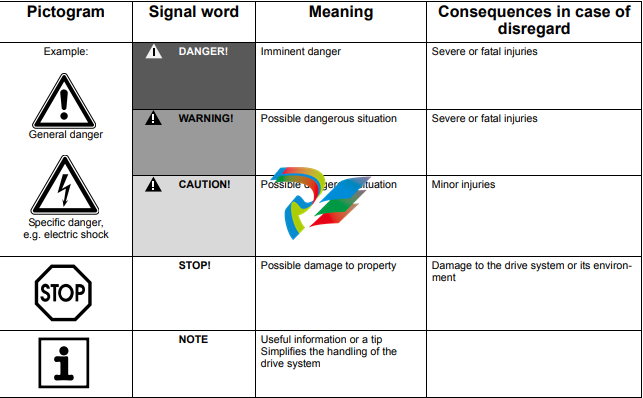

The safety notes in these operating instructions are designed as follows:

Pictogram SIGNAL WORD!

Type and source of danger.

Possible consequence(s) if the safety notes are disregarded.

• Measure(s) to prevent the danger

[1] Power shield clamp for mains connection and connection for DC link connection

[2] X4: Connection for DC link connection UZ– / UZ+ and PE connection, separable

[3] X1: Power supply connection L1, L2, L3 and PE connection, separable

[4] Only with MDX61B: Fieldbus slot

[5] Only with MDX61B: Encoder slot

[6] Electronics shield clamp MDX61B size 0

[7] X10: Electronics terminal strip for binary outputs and TF/TH input

[8] X16: Electronics terminal strip for binary inputs and outputs

[9] X13: Electronics terminal strip for binary inputs and RS-485 interface

[10] X11: Electronics terminal strip for setpoint input AI1 and 10 V reference voltage

[11] X12: Electronics terminal strip for system bus (SBus)

[12] DIP switches S11 ... S14

[13] XT: Slot for DBG60B keypad or UWS21B serial interface

[14] 7-segment display

[15] Memory card

[16] Electronics shield clamp MDX60B size 0

[17] X17: Electronics terminal strip for safety contacts for safe stop

[18] X2: Motor connection U, V, W and PE connection, separable

[19] X3: Braking resistor connection +R / –R and PE connection, separable

[20] Power shield clamp for motor connection and braking resistor connection

Exclusion of liability:

You must comply with the information contained in these operating instructions

MDX61B-5A3 (AC 400/500 V units): 0015 ... 0040

MDX61B-2A3 (AC 230 V units): 0015 ... 0037

to ensure safe operation of the MOVIDRIVE® MDX60B/61B drive inverters and to

achieve the specified product characteristics and performance requirements.

SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions.

In such cases, any liability for defects is excluded.

Safety Notes

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must make sure that the basic safety notes are read

and observed. Make sure that persons responsible for the plant and its operation, as

well as persons who work independently on the unit, have read through the operating

instructions carefully and understood them. If you are unclear about any of the information in this documentation, or if you require further information, please contact SEW-EURODRIVE.

2.1 General information

Never install damaged products or take them into operation. Submit a complaint to the

shipping company immediately in the event of damage.

During operation, drive inverters can have live, bare and movable or rotating parts as

well as hot surfaces, depending on their enclosure.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to machinery.

Consult the documentation for additional information.

2.2 Target group

Only qualified electricians are authorized to install, startup, troubleshoot or service the

units (observe IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and IEC 60664 or

DIN VDE 0110 as well as national accident prevention guidelines).

Qualified personnel in the context of these basic safety notes are: All persons familiar

with installation, assembly, startup and operation of the product who possess the necessary qualifications.

All work related to transport, storage, operation and disposal must be carried out only

by personnel who have been trained and instructed accordingly.

2.3 Designated use

Drive inverters are components intended for installation in electrical systems or machines.

In case of installation in machines, startup of the drive inverters (i.e. start of designated

operation) is prohibited until it is determined that the machine meets the requirements

stipulated in the EC Directive 98 37 EC (machine guideline); observe EN 60204.

Startup (i.e. start of designated operation) is only permitted with adherence to EMC

(89/336/EEC) guideline.

The drive inverters meet the requirements stipulated in low voltage guideline

73/23/EEC. The harmonized standards of the EN 61800-5-1/DIN VDE T105 series in

connection with EN 60439-1/VDE 0660 part 500 and EN 60146/VDE 0558 are applied

to these drive inverters.

Technical data and information on the connection requirements are given on the nameplate and in the documentation; they have to be observed under all circumstances.

Safety functions The MOVIDRIVE® MDX60B/61B drive inverters may not perform safety functions without higher-level safety systems. Use higher-level safety systems to ensure protection of

equipment and personnel.

For safety applications, refer to the information in the following publications:

• Safe Disconnection for MOVIDRIVE® MDX60B/61B – Conditions

• Safe Disconnection for MOVIDRIVE® MDX60B/61B – Applications

2.4 Transportation, putting into storage

Observe the notes on transportation, storage and proper handling. Observe the climatic

conditions as stated in the section "General technical data."

2.5 Installation

Installation and cooling of the devices must take place according to the guidelines listed

.png)

.png)

.png)