REXRTOHECODRIVE03 Drive ControllersProject Planning Manual

"ECODRIVE03 Drive for General Automation With Fieldbus-Interfaces"

- Functional Description -

DOK-ECODR3-FGP-03VRS**-FKxx-EN-P

"LWL - Handling"

- Application Manual -

DOK-CONNEC-CABLE*LWL-AWxx-EN-P

"Electromagnetic Compatibility (EMC) in Drive and Control Systems"

- Project Planning Manual -

DOK-GENERL-EMV********-PRxx-EN-P

"Digital AC Motors MKD"

- Project Planning Manual -

DOK-MOTOR*-MKD********-PRxx-EN-P

"Digital AC Motors MHD"

- Project Planning Manual -

DOK-MOTOR*-MHD********-PRxx-EN-P

"MKE Digital AC Motors for potentially explosive areas"

- Project Planning Manual -

DOK-MOTOR*-MKE********-PRxx-EN-P

"2AD AC Motor"

- Project Planning Manual -

DOK-MOTOR*-2AD********-PRxx-EN-P

"ADF Main Spindle Motors"

- Project Planning Manual -

DOK-MOTOR*-ADF********-PRxx-EN-P

"1MB Frameless Spindle Motor"

- Project Planning Manual -

DOK-MOTOR*-1MB********-PRxx-EN-P

"Synchronous MBS Kit Spindle Motors"

- Project Planning Manual -

DOK-MOTOR*-MBS********-PRxx-EN-P

LAR 070-132 Gehäuse-Linearmotoren

- Selection and Project Planning -

DOK-MOTOR*-LAR********-AWxx-DE-P

"LAF050 – 121 Linear Motors"

- Selection and Project Planning -

DOK-MOTOR*-LAF********-AWxx-EN-P

"Linear Synchronous Direct Drives LSF"

- Project Planning Manual -

DOK-MOTOR*-LSF********-PRxx-EN-P

"AC Drive Units in Personnel Conveyor Systems"

- Application Manual -

DOK-GENERL-ANTR*PERSON-ANxx-EN-P

"AC Drive Units in Hazardous Areas (Expl. Protection)"

- Application Manual -

DOK-GENERL-ANTR*EXPLOS-ANxx-EN-P

"ECODRIVE03 Drive for Machine Tool Applications With SERCOS-,

Analog- and Parallelinterface"

- Troubleshooting Guide -

DOK-ECODR3-SMT-01VRS**-WAR*-EN-P

"ECODRIVE03 Drive for Machine Tool Applications With SERCOS-,

Analog- and Parallelinterface"

- Troubleshooting Guide -

DOK-ECODR3-SMT-02VRS**-WAR*-EN-P

"ECODRIVE03 Drive for General Automation With SERCOS-, Analogand Parallelinterface"

- Troubleshooting Guide -

DOK-ECODR3-SGP-01VRS**-WAxx-EN-P

"ECODRIVE03 Drive for General Automation With Fieldbus-Interfaces"

- Troubleshooting Guide -

DOK-ECODR3-FGP-01VRS**-WAxx-EN-P

"ECODRIVE03 Drive for General Automation With Fieldbus-Interfaces"

- Troubleshooting Guide -

DOK-ECODR3-FGP-02VRS**-WAxx-EN-P

"ECODRIVE03 Drive for General Automation With Fieldbus-Interfaces"

- Troubleshooting Guide -

DOK-ECODR3-FGP-03VRS**-WAxx-EN-P

"DOLFI, Auxiliary for Download Firmware"

- Application Manual -

DOK-DOLFI DO01D**W

ntroduction to the System

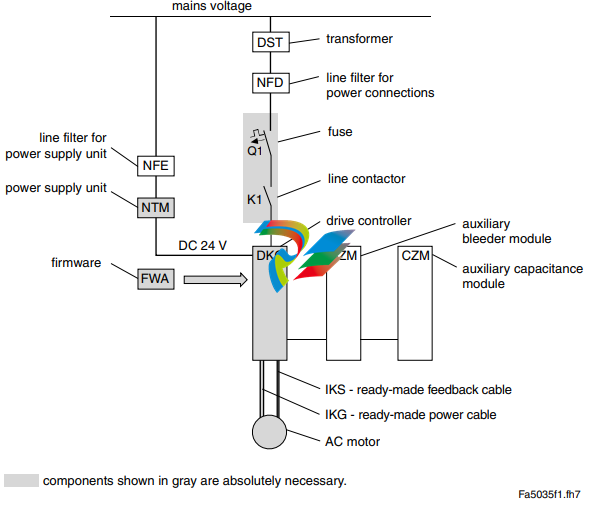

1.1 Drive package ECODRIVE03

The digital intelligent automation system ECODRIVE03 is the costeffective solution with a high level of functionality for single and multiple

axis drive and control tasks.

ECODRIVE03 can be used to implement a variety of drive tasks in the

most varied applications. Different device types are available with

graduated drive power.

Typical application areas are:

• handling systems

• packaging machines

• assembly systems

• printing machines

• machine tools

An Overview of Individual Components of the

ECODRIVE03 Family

An Overview of Drive Controllers and Auxiliary

Components

An Overview of Communications Interfaces

mportant directions for use 2.1 Appropriate use Introduction Rexroth Indramat products represent state-of-the-art developments and manufacturing. They are tested prior to delivery to ensure operating safety and reliability. The products may only be used in the manner that is defined as appropriate. If they are used in an inappropriate manner, then situations can develop that may lead to property damage or injury to personnel. Note: Rexroth Indramat, as manufacturer, is not liable for any damages resulting from inappropriate use. In such cases, the guarantee and the right to payment of damages resulting from inappropriate use are forfeited. The user alone carries all responsibility of the risks. Before using Rexroth Indramat products, make sure that all the prerequisites for an appropriate use of the products are satisfied: • Personnel that in any way, shape or form uses our products must first read and understand the relevant safety instructions and be familiar with appropriate use. • If the product takes the form of hardware, then they must remain in their original state, in other words, no structural changes are permitted. It is not permitted to decompile software products or alter source codes. • Do not mount damaged or faulty products or use them in operation. • Make sure that the products have been installed in the manner described in the relevant documentation.

Areas of use and application

Drive controllers made by Rexroth Indramat are designed to control

electrical motors and monitor their operation.

Control and monitoring of the motors may require additional sensors and

actors.

Note: The drive controllers may only be used with the accessories

and parts specified in this document. If a component has not

been specifically named, then it may not be either mounted or

connected. The same applies to cables and lines.

Operation is only permitted in the specified configurations and

combinations of components using the software and firmware

as specified in the relevant function descriptions.

Every drive controller has to be programmed before starting it up, making

it possible for the motor to execute the specific functions of an application.

The drive controllers of the ECODRIVE03 family are designed for use in

single or multiple-axis drive and control applications.

To ensure an application-specific use, the drive controllers are available

with differing drive power and different interfaces.

Typical applications of drive controllers belonging to the ECODRIVE03

family are:

• handling and mounting systems,

• packaging and foodstuff machines,

• printing and paper processing machines and

• machine tools.

The drive controllers may only be operated under the assembly,

installation and ambient conditions as described here (temperature,

system of protection, humidity, EMC requirements, etc.) and in the

position specified.

2.2 Inappropriate use

Using the drive controllers outside of the above-referenced areas of

application or under operating conditions other than described in the

document and the technical data specified is defined as “inappropriate

use".

Drive controllers may not be used if

• they are subject to operating conditions that do not meet the above

specified ambient conditions. This includes, for example, operation

under water, in the case of extreme temperature fluctuations or

extremely high maximum temperatures or if

• Rexroth Indramat has not specifically released them for that intended

purpose. Please note the specifications outlined in the general safety

instructions!

Safety Instructions for Electric Drives and Controls

3.1 Introduction

Read these instructions before the initial startup of the equipment in order

to eliminate the risk of bodily harm or material damage. Follow these

safety instructions at all times.

Do not attempt to install or start up this equipment without first reading all

documentation provided with the product. Read and understand these

safety instructions and all user documentation of the equipment prior to

working with the equipment at any time. If you do not have the user

documentation for your equipment, contact your local Rexroth Indramat

representative to send this documentation immediately to the person or

persons responsible for the safe operation of this equipment.

If the equipment is resold, rented or transferred or passed on to others,

then these safety instructions must be delivered with the equipment.

WARNING

Improper use of this equipment, failure to follow

the safety instructions in this document or

tampering with the product, including disabling

of safety devices, may result in material

damage, bodily harm, electric shock or even

death!

3.2 Explanations

The safety instructions describe the following degrees of hazard

seriousness in compliance with ANSI Z535. The degree of hazard

seriousness informs about the consequences resulting from noncompliance with the safety instructions.

Warning symbol with signal

word

Degree of hazard seriousness according

to ANSI

DANGER

Death or severe bodily harm will occur.

WARNING

Death or severe bodily harm may occur.

CAUTION

Bodily harm or material damage may occur

Hazards by Improper Use

DANGER

High voltage and high discharge current!

Danger to life or severe bodily harm by electric

shock!

DANGER

Dangerous movements! Danger to life, severe

bodily harm or material damage by

unintentional motor movements!

WARNING

High electrical voltage due to wrong

connections! Danger to life or bodily harm by

electric shock!

WARNING

Health hazard for persons with heart

pacemakers, metal implants and hearing aids in

proximity to electrical equipment!

CAUTION

Surface of machine housing could be extremely

hot! Danger of injury! Danger of burns!

CAUTION

Risk of injury due to improper handling! Bodily

harm caused by crushing, shearing, cutting and

mechanical shock or incorrect handling of

pressurized systems!

CAUTION

Risk of injury due to incorrect handling of

batteries!

General Information

• Rexroth Indramat GmbH is not liable for damages resulting from

failure to observe the warnings provided in this documentation.

• Read the operating, maintenance and safety instructions in your

language before starting up the machine. If you find that you cannot

completely understand the documentation for your product, please ask

your supplier to clarify.

• Proper and correct transport, storage, assembly and installation as

well as care in operation and maintenance are prerequisites for

optimal and safe operation of this equipment.

• Only persons who are trained and qualified for the use and operation

of the equipment may work on this equipment or within its proximity.

The persons are qualified if they have sufficient knowledge of the

assembly, installation and operation of the equipment as well as an

understanding of all warnings and precautionary measures noted in

these instructions.

Furthermore, they must be trained, instructed and qualified to switch

electrical circuits and equipment on and off in accordance with

technical safety regulations, to ground them and to mark them

according to the requirements of safe work practices. They must

have adequate safety equipment and be trained in first aid.

• Only use spare parts and accessories approved by the manufacturer.

• Follow all safety regulations and requirements for the specific

application as practiced in the country of use.

• The equipment is designed for installation in industrial machinery.

• The ambient conditions given in the product documentation must be

observed.

• Use only safety features and applications that are clearly and explicitly

approved in the Project Planning Manual.

For example, the following areas of use are not permitted: construction

cranes, elevators used for people or freight, devices and vehicles to

transport people, medical applications, refinery plants, transport of

hazardous goods, nuclear applications, applications sensitive to high

frequency, mining, food processing, control of protection equipment

(also in a machine).

• The information given in this documentation with regard to the use of

the delivered components contains only examples of applications and

suggestions.

The machine and installation manufacturer must

make sure that the delivered components are suited for his individual

application and check the information given in this documentation

with regard to the use of the components,

make sure that his application complies with the applicable safety

regulations and standards and carry out the required measures,

modifications and complements.

• Startup of the delivered components is only permitted once it is sure

that the machine or installation in which they are installed complies

with the national regulations, safety specifications and standards of the

application.

• Operation is only permitted if the national EMC regulations for the

application are met.

The instructions for installation in accordance with EMC requirements

can be found in the documentation "EMC in Drive and Control

Systems".

The machine or installation manufacturer is responsible for

compliance with the limiting values as prescribed in the national

regulations.

• Technical data, connections and operational conditions are specified in

the product documentation and must be followed at all times.

Protection Against Contact with Electrical Parts

Note: This section refers to equipment and drive components with

voltages above 50 Volts.

Touching live parts with voltages of 50 Volts and more with bare hands or

conductive tools or touching ungrounded housings can be dangerous and

cause electric shock. In order to operate electrical equipment, certain

parts must unavoidably have dangerous voltages applied to them.

DANGER

High electrical voltage! Danger to life, severe

bodily harm by electric shock!

⇒ Only those trained and qualified to work with or on

electrical equipment are permitted to operate, maintain

or repair this equipment.

⇒ Follow general construction and safety regulations when

working on high voltage installations.

⇒ Before switching on power the ground wire must be

permanently connected to all electrical units according

to the connection diagram.

⇒ Do not operate electrical equipment at any time, even

for brief measurements or tests, if the ground wire is not

permanently connected to the points of the components

provided for this purpose.

⇒ Before working with electrical parts with voltage higher

than 50 V, the equipment must be disconnected from

the mains voltage or power supply. Make sure the

equipment cannot be switched on again unintended.

⇒ The following should be observed with electrical drive

and filter components:

⇒ Wait five (5) minutes after switching off power to allow

capacitors to discharge before beginning to work.

Measure the voltage on the capacitors before beginning

to work to make sure that the equipment is safe to

touch.

⇒ Never touch the electrical connection points of a

component while power is turned on.

⇒ Install the covers and guards provided with the

equipment properly before switching the equipment on.

Prevent contact with live parts at any time.

⇒ A residual-current-operated protective device (RCD)

must not be used on electric drives! Indirect contact

must be prevented by other means, for example, by an

overcurrent protective device.

⇒ Electrical components with exposed live parts and

uncovered high voltage terminals must be installed in a

protective housing, for example, in a control cabinet.

.png)

.png)

.png)