MOVITRAC® 07System Manual 1056 2915 / EN

• Inputs and outputs programmable

– 1 analog input

– 5 binary inputs

– 2 binary outputs, 1 of which is a relay output

• Integrated voltage supply and evaluation for TF (PTC temperature sensor) for temperature monitoring of the motor.

• Integrated operating panel for displaying setpoints and setting parameters

– 10 LEDs for displaying the selected symbols

– 5 operation buttons

– 1 setpoint potentiometer for specifying the speed

• Braking resistor can be integrated as an option in sizes 0S, 0M and 0L.

Control functions • VFC control mode or V/f control.

• Automatic brake control by the inverter.

• DC braking to decelerate the motor even in 1-quadrant mode.

• Slip compensation for high static speed accuracy.

• Motor pull-out protection by sliding current limitation in the field weakening range.

• Factory settings can be reactivated.

• Parameter lock to protect against parameter changes

• Protective features to protect against

– Overcurrent

– Ground fault

– Overload

– Overtemperature of the inverter

– Overtemperature of the motor

• Speed monitoring and monitoring of the motor and regenerative limit power.

• Fault memory with all relevant operating data at the moment of the fault.

• Standardized operation, parameter setting and identical unit connection technology

across all units in the MOVITRAC® 07 range.

Setpoint technology

• Motor potentiometer.

• External setpoint selections:

– 0 ... +10 V

– 0 ... 20 mA

– 4 ... 20 mA

• 6 fixed setpoints.

• Frequency input (in preparation).

Communication /

operation

• System bus for networking max. 64 MOVITRAC® 07 units.

• RS-485 interface for service purposes.

• Straightforward parameter setting and startup using integrated operating panel or

MOVITOOLS® PC software.

• LOGODrive graphical programming interface for writing programs.

• Parameter module for saving and transferring inverter data including the LOGODrive

program.

• Fieldbus interfaces for

– PROFIBUS

– DeviceNet

– INTERBUS

– CANopen

Extended functions:

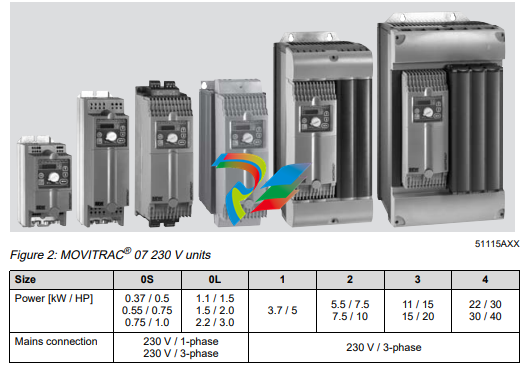

230 V units from 3.7 kW onwards, 500 V units from 5.5 kW onwards and LOGODrive

units offer an expanded range of functions including:

• Standstill current function for:

– Rapid start

– Heating current for avoiding condensation at low temperatures

• Flying restart circuit for flying restart of the inverter.

• Hoisting capability with all approved motor options.

General technical data

The following technical data applies to all MOVITRAC® 07 frequency inverters, regardless of size

MOVITRAC® 07 All sizes

Interference immunity To EN 61800-3

Interference emission with

EMC-compliant installation

To limit value class

• B: 1-phase connection

• A: 3-phase connection

– 230 V: 0.37 ... 7.5 kW

– 400/500 V: 0.55 ... 11 kW

To EN 55011 and EN 55014; complies with EN 61800-3

Discharge current > 3.5 mA

Ambient temperature ϑamb

at fPWM = 4 kHz

230 V, 0.37 ... 2.2 kW

400/500 V, 0.55 ... 4.0 kW

• –10 °C ... +50 °C at 100 % IN

• –10 °C ... +40 °C at 125 % IN

230 V, 3.7 ... 30 kW

400/500 V, 5.5 ... 30 kW

• 0 °C – +50 °C at 100 % IN

• 0 °C ... +40 °C at 125 % IN

Power reduction 3.0 % IN per K to max. 60 °C

Climate class EN 60721-3-3, class 3K3

Storage temperature1

Transport temperature

1 If the unit is being stored for a long time, connect it to the mains voltage for at least 5 minutes every 2

years. Otherwise, the service life of the unit will be reduced.

–25 °C ... +75 °C

–25 °C ... +75 °C

Enclosure IP20

Size 4 power connections: IP00, IP10 with Plexiglas cover

mounted (supplied as standard)

Operating mode Continuous duty (EN 60149-1-1 and 1-3)

Altitude h ≤ 1000 m (3300 ft)

• IN reduction

– 1 % per 100 m (330 ft)

– From 1000 m to max. 4000 m (3300 ft to max. 13,200 ft)

• VN reduction

– 3 V per 100 m (330 ft)

– From 2000 m to max. 4000 m (6600 ft to max. 13,200 ft)

Over 200 m (6600 ft) only overvoltage class 2, external measures are required for overvoltage class 3. Overvoltage classes

to DIN VDE 0110-1.

Vibration-resistance To EN 50 178 / VDE 0160

Technical data of MOVITRAC® 07

.png)

.png)

.png)