MOVITRAC® 07System Manual 1056 2915 / EN

1 Important Notes

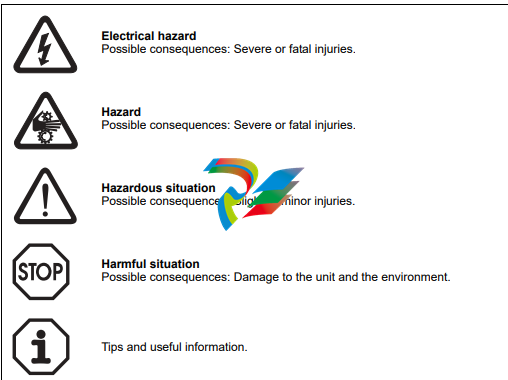

Safety and warning instructions

Always follow the safety and warning instructions contained in this publication!

Unless the information in the operating instructions is adhered to, it will be impossible to

ensure:

• Trouble-free operation

• Fulfillment of any rights to claim under guarantee

Consequently, read the operating instructions before you start working with the unit!

The operating instructions contain important information about servicing. Therefore,

keep the operating instructions close to the unit.

Designated use MOVITRAC® 07 frequency inverters operate AC asynchronous motors. These motors

must be suitable for operation with frequency inverters. Do not connect any other loads

to the frequency inverters.

MOVITRAC® 07 frequency inverters are units intended for stationary installation in

switch cabinets. All instructions referring to the technical data and the permissible conditions where the unit is operated must be followed.

Do not start up the unit (take it into operation in the designated fashion) until:

• The machine complies with the EMC Directive 89/336/EEC

• The conformity of the end product has been determined in accordance with the Machinery Directive 89/392/EEC (with reference to EN 60204)

Application environment

The following applications are forbidden unless measures are expressly taken to make

them possible:

• Use in explosion-proof areas

• Use in environments with harmful substances:

– Oils

– Acids

– Gases

– Vapors

– Dust

– Radiated interference

– Other harmful environments

• Use subject to mechanical vibration and shock loads in excess of the requirements

in EN 50178

• If the inverter performs safety functions which have to guarantee the protection of

machinery and people

Waste disposal Please follow the current instructions: Dispose in accordance with the regulations in

force:

• Electronics scrap (printed-circuit boards)

• Plastic (housing)

• Sheet metal

• Copper

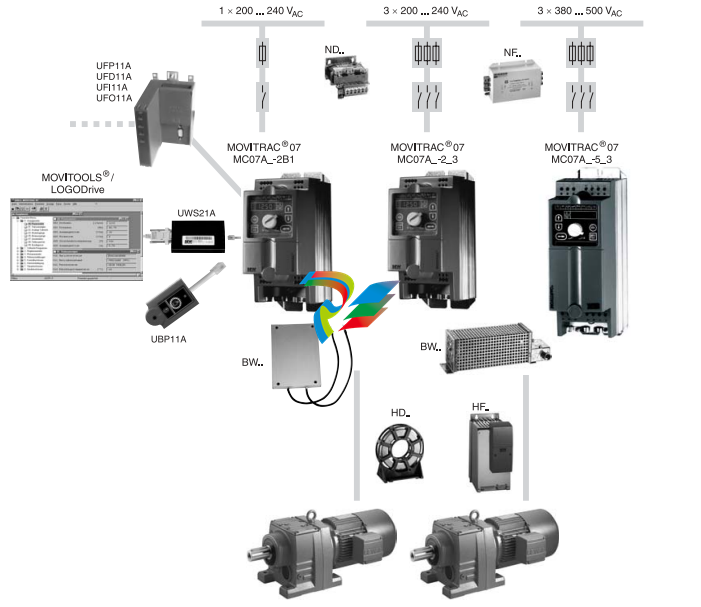

System Description

2.1 Overview of the system

Overview of properties

Compact The unit has a very compact structure

• Integrated brake chopper

• Integrated EMC line filter:

– Class B: 1-phase connection

– Class A: 3-phase connection

– 230 V: 0.37 ... 7.5 kW

– 400/500 V: 0.55 ... 11 kW

• Braking resistor can be integrated (optional for sizes 0S, 0M, 0L)

• Book-shaped design with IP20 enclosure / NEMA1 (size 4: IP00, with touch guard

IP10)

Straightforward Startup and operation are very straightforward

• Automatic motor adaptation

• Integrated operating panel with menu structure

• Startup based on the "plug and play" principle

• Integrated setpoint potentiometer

• Easy parameter setting and diagnosis using MOVITOOLS® PC software

Right for the job The unit has the right function for every application

• Standard V/f control process or field-oriented VFC control mode as an option

• High overload capacity

– 125 % IN continuous duty (fan/pump operation)

– 150 % IN for maximum 60 seconds

– Maximum 180 % breakaway torque

• Integrated PI-controller

• Extended temperature range

– –10 °C ... +50 °C

– 230 V: 0.37 ... 2.2 kW

– 400/500 V: 0.55 ... 4.0 kW

– 0 °C ... +50 °C

– 230 V: 3.7 ... 30 kW

– 400/500 V: 5.5 ... 30 kW

• Integrated protection and monitoring functions

– Short circuit

– Ground fault

– Motor temperature sensor

System bus With the system bus (SBus) fitted as standard, you can network up to 64 MOVITRAC®

07 frequency inverters as slaves. A PC, a PLC or a MOVIDRIVE® can be the SBus master.

The MOVITRAC® 07 Communication manual describes the functions of the system bus.

Extended functions:

230 V units from 3.7 kW onwards and 500 V units from 5.5 kW onwards offer an extended range of functions including:

• Flying restart circuit

• Hoisting function

• Setpoint stop function

• Master frequency

• Standstill current function

• SCOPE oscilloscope program for MOVITOOLS®

LOGODrive units There is the LOGODrive series of units as well as the standard series. These differ from

the standard series in the following respects:

• The optional LOGODrive graphical programming interface is integrated in the

MOVITOOLS® software from version 2.6 onwards. You can add and link function

blocks into a sequential function chart graphically using LOGODrive.

• LOGODrive units also have the extended functions.

There is a separate manual for the LOGODrive graphical programming interface.

2.3 Functions / features

MOVITRAC® 07 frequency inverters are characterized by the following attributes:

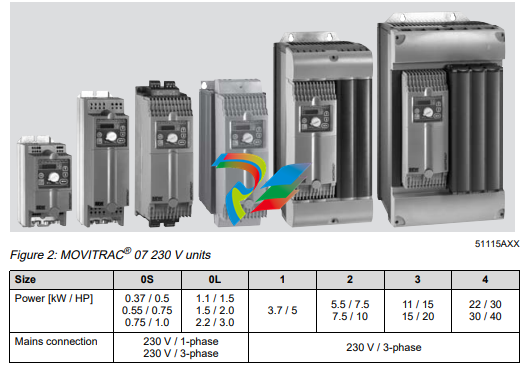

Unit properties • Wide voltage range:

– 230 V units 1-phase and 3-phase for the voltage range 200 ... 240 VAC, 50/60 Hz

– 400/500 V units for the voltage range 3 x 380 ... 500 VAC, 50/60 Hz

• Overload capacity: 150 % IN for maximum 60 s

125 % IN continuous power (fan/pump operation)

Maximum 180 % breakaway torque

• Rated operation (IN = 100 %) up to ambient temperature ϑ = 50 °C.

• 4-quadrant capability due to the integrated brake chopper.

• Compact unit mounting position for minimum switch cabinet space requirement and

optimum utilization of switch cabinet volume.

• Integrated EMC line filter to EN 55011 for compliance with limit value class:

– Class B: 1-phase connection

– Class A: 3-phase connection

– 230 V: 0.37 ... 7.5 kW

– 400/500 V: 0,55 ... 11 kW

• Inputs and outputs programmable

– 1 analog input

– 5 binary inputs

– 2 binary outputs, 1 of which is a relay output

• Integrated voltage supply and evaluation for TF (PTC temperature sensor) for temperature monitoring of the motor.

• Integrated operating panel for displaying setpoints and setting parameters

– 10 LEDs for displaying the selected symbols

– 5 operation buttons

– 1 setpoint potentiometer for specifying the speed

• Braking resistor can be integrated as an option in sizes 0S, 0M and 0L.

Control functions • VFC control mode or V/f control.

• Automatic brake control by the inverter.

• DC braking to decelerate the motor even in 1-quadrant mode.

• Slip compensation for high static speed accuracy.

• Motor pull-out protection by sliding current limitation in the field weakening range.

• Factory settings can be reactivated.

• Parameter lock to protect against parameter changes

• Protective features to protect against

– Overcurrent

– Ground fault

– Overload

– Overtemperature of the inverter

– Overtemperature of the motor

• Speed monitoring and monitoring of the motor and regenerative limit power.

• Fault memory with all relevant operating data at the moment of the fault.

• Standardized operation, parameter setting and identical unit connection technology

across all units in the MOVITRAC® 07 range.

Setpoint technology

• Motor potentiometer.

• External setpoint selections:

– 0 ... +10 V

– 0 ... 20 mA

– 4 ... 20 mA

• 6 fixed setpoints.

• Frequency input (in preparation).

Communication /

operation

• System bus for networking max. 64 MOVITRAC® 07 units.

• RS-485 interface for service purposes.

• Straightforward parameter setting and startup using integrated operating panel or

MOVITOOLS® PC software.

• LOGODrive graphical programming interface for writing programs.

• Parameter module for saving and transferring inverter data including the LOGODrive

program.

• Fieldbus interfaces for

– PROFIBUS

– DeviceNet

– INTERBUS

– CANopen

Extended functions:

230 V units from 3.7 kW onwards, 500 V units from 5.5 kW onwards and LOGODrive

units offer an expanded range of functions including:

• Standstill current function for:

– Rapid start

– Heating current for avoiding condensation at low temperatures

• Flying restart circuit for flying restart of the inverter.

• Hoisting capability with all approved motor options.

General technical data

The following technical data applies to all MOVITRAC® 07 frequency inverters, regardless of size

MOVITRAC® 07 All sizes

Interference immunity To EN 61800-3

Interference emission with

EMC-compliant installation

To limit value class

• B: 1-phase connection

• A: 3-phase connection

– 230 V: 0.37 ... 7.5 kW

– 400/500 V: 0.55 ... 11 kW

To EN 55011 and EN 55014; complies with EN 61800-3

Discharge current > 3.5 mA

Ambient temperature ϑamb

at fPWM = 4 kHz

230 V, 0.37 ... 2.2 kW

400/500 V, 0.55 ... 4.0 kW

• –10 °C ... +50 °C at 100 % IN

• –10 °C ... +40 °C at 125 % IN

230 V, 3.7 ... 30 kW

400/500 V, 5.5 ... 30 kW

• 0 °C – +50 °C at 100 % IN

• 0 °C ... +40 °C at 125 % IN

Power reduction 3.0 % IN per K to max. 60 °C

Climate class EN 60721-3-3, class 3K3

Storage temperature1

Transport temperature

1 If the unit is being stored for a long time, connect it to the mains voltage for at least 5 minutes every 2

years. Otherwise, the service life of the unit will be reduced.

–25 °C ... +75 °C

–25 °C ... +75 °C

Enclosure IP20

Size 4 power connections: IP00, IP10 with Plexiglas cover

mounted (supplied as standard)

Operating mode Continuous duty (EN 60149-1-1 and 1-3)

Altitude h ≤ 1000 m (3300 ft)

• IN reduction

– 1 % per 100 m (330 ft)

– From 1000 m to max. 4000 m (3300 ft to max. 13,200 ft)

• VN reduction

– 3 V per 100 m (330 ft)

– From 2000 m to max. 4000 m (6600 ft to max. 13,200 ft)

Over 200 m (6600 ft) only overvoltage class 2, external measures are required for overvoltage class 3. Overvoltage classes

to DIN VDE 0110-1.

Vibration-resistance To EN 50 178 / VDE 0160

Technical data of MOVITRAC® 07

.png)

.png)

.png)