ABB AC160Industrial Networks Connecting Controllers via OPC

Abstract

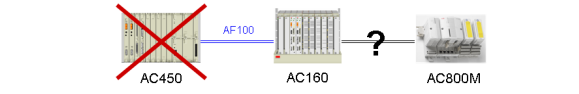

In order to modernize their infrastructure and keep up with the state

of the art, ABB Power Systems decided to replace the older controller

AC450 with a new generation of controllers called AC800M. Just like i

ts predecessor, its main task is to work as a sequencer in an otherwis

e mostly unchanging topology. Although the new controller AC800M

provides modern communication features and a sophisticated applica

ion development system, it lacks of a communication interface compa

tible with the residing controllers AC160. A hardware approach addres

sing this problem is in development, but not available at this point of t

ime. Thus the decision was made to realize the connection using OPC,

a widely spread and open software communication interface standard

with a high potential of reusability. In addition, it was aimed at gainin

g additional knowledge about the OPC interface, which is commonly u

sed in industry. In this thesis, we evaluate adequate hardware and sof

tware to realize this connection and we have programmed the controll

ers with applications to evaluate its performance and integrity. In add

ition, we are making considerations about redundancy that is vital in

automation business in order to increase reliability and availability. W

e have shown that it is possible to interconnect controllers using OPC

with satisfactory average performance results. Due to high maximum

round trip times and high complexity when realizing redundancy, it is

recommended to use such a system for testing purposes or non-critica

l operational applications, but not for critical systems. In this thesis we

also identify and judge several alternative ways of connection.

Acknowledgements

First of all, I would like to thank Prof. Dr. Bernhard Plattner of the Computer

Engineering and Networks Laboratory TIK at the Swiss Federal Institute of Technology ETH Zurich for supporting and supervising this Master’s Thesis. Special

thanks go to my advisors Rainer Baumann and Bernhard Tellenbach of TIK for

their straightforward and helpful support during my work.

Secondly I would like to thank Dr. Esther Gelle and Pascal Aebli of ABB for

enabling this Master’s Thesis in the first place as well as providing aid throughout

this thesis. Special thanks also to Stephan Egli for supporting me with the first

steps, Swen Woldau for numerous hints concerning AC160 and AF100 as well as

Juerg Beck for AC800M tips and tricks. Finally I would like to thank everyone else

at PSPD for the provided aid and making my work so convenient not only in a

technical but also in a human manner.

Baden, June 2007

Martin Pfister

Introduction

This chapter will provide a rough overview of the problem treated by this Master’s

Thesis. All technical devices and expressions will be explained more precisely in

the next chapter. Please note that since this is a public thesis, it does not contain

sensitive company-internal data.

ABB Power Systems

ABB Power Systems is one of the world’s leading providers of infrastructure for

controlling combined cycle power stations and waste-to-energy plants. Such a

plant control infrastructure includes several hardware parts consisting of controllers,

input/output-boards and communication devices as well as many software components to engineer, run, observe and analyze the power plant. A power plant control

system has to satisfy a broad variety of different needs, from the efficient and reliable control of the turbines and associated supporting functions (such as lube oil)

to easy configuration and operation as well as to sophisticated analysis functions

addressing technical and economical aspects.

Problem Statement

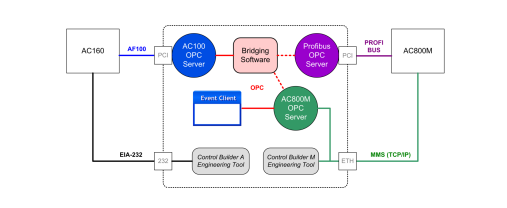

Due to high investment costs, the technical management of power plants is a slowgoing business with long life-cycles. Thus, a considerable amount of hardware devices currently in use are tens of years old. For future applications within ABB Power Systems it will be necessary to connect a controller of the newest series used within ABB, Control IT AC800M, with an older controller of the type Advant Controller 160 (AC160). The problem is that these two controllers do not share a fast communication interface of similar type and therefore cannot communicate directly. The standard communication intended for AC160 is Advant Fieldbus 100 (AF100). However, AC800M can support a whole range of buses except for AF100. As a consequence, the communication must be implemented using some relaying technique.

1.2.1 The Use of OPC

It was decided in advance to realize the relaying connection using OPC. This solution was chosen because OPC is an open standard and very common in process and automation industry. Furthermore, this solution offers a high potential to be used for similar problems, since a lot of devices support this specification. However, OPC is normally not used for fast controller-to-controller communication but for slower visualization and logging purposes and there is no performance data available for this kind of connection. The use of OPC is therefore both challenging as well as interesting to gain more insights and know-how. It is also to mention that a hardware solution addressing our problem is not available yet. It is therefore necessary to have an alternative way using already available parts, also for testing purposes.

1.3 Goals

The goals of this Master’s Thesis are stated as follows:

• Setup and evaluation of a test environment

• Setup of test systems

• Theoretical and practical evaluation of the test systems concerning performance, availability and reliability.

• Identification of improvements and different approaches

• Comparison with alternatives As a starting point for the performance requirements, the current implementation was taken. The corresponding quantity and type of variables are displayed in Table 1.1 with 32-bit floating point values (floats) as analog in- and outputs and 1-bit boolean values as so-called status and command bits. In the current configuration with AC450 and AC160, all variables are written to the AF100 fieldbus with a cycle time of 256 milliseconds. Therefore we determined the minimum requirement for round-trip times from one controller to the other to exactly this time. In agreement with the advisors, instead of elaborating the optional extension stated in the task description (Appendix C), we spent more time on trying out a

1.4 Structure

For the reader’s convenience this Master’s Thesis is structured thematically starting with an overview of components and terms

(2) in the next chapter. The following chapters inform about the test system setup

(3), the evaluations that were made

(4) and finally the results

(5). In a subsequent chapter the subject redundancy is treated

(6) before the thesis comes to an end with the conclusion and outlook

(7). Additional information as well as a CD-ROM containing more detailed data is

located in the appendix of this thesis.

Chapter 2

Components and Terms

In this chapter, hardware and software parts as well as terms used for our test

system and evaluations will be described. Some additional devices and programs

concerning redundancy are introduced not until the chapter according. Information

on the version numbers can be found in Appendix B.

2.1 Basic Terms

• Performance, in this thesis, refers to the capability of a communication component in means of speed and throughput.

• Availability is the term for the probability that a system will perform its specified functions when used under stated conditions. A common mathematical definition of operational availability is Ao = MT BF/(MT BF + MDT), whereas MTBF is the “mean time between failure” and MDT the “mean down time” [2]. However, in this thesis, availability is used in a more general manner, since the basis for mathematical operations is not available

• Reliability means the probability of a device remaining failure free during a specified time interval, e.g. the maintenance interval: R = e λt

• Redundancy is the implementation of extra components in addition to the ones needed for normal operation. Thus, redundancy normally increases reliability and availability

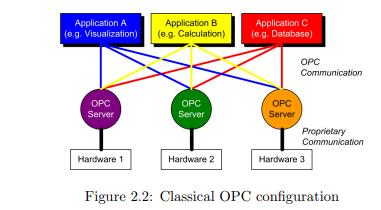

2.2 OPC

OPC, originally short for “OLE for Process Control”, is an open, standardized

software communication interface specification launched in 1996 by a task force of

different automation companies, later forming the OPC Foundation. As the former

name indicates, OPC is an adaption of Microsoft’s Object Linking and Embedding

OLE1

to the process control business, which used to be highly proprietary at that

point of time. Thus it was almost impossible to efficiently combine products of

different vendors. By providing so-called OPC servers with their devices, buses and

software, vendors open their products to any OPC compliant client able to connect

to the server for data exchange. Usually, an OPC server can handle several clients

at once, while these clients—e.g. visualization or calculation applications—can connect to different servers in order to obtain their needed information.

Over the years, the OPC Foundation has been adding eight additional specifications to the original one, therefore the name OPC was freed from its original meaning and is now used as an umbrella term [3]. Some important specifications are quickly explained in the following:

•DA (Data Access) is the original and most widely used standard of OPC. Its purpose is the cyclic polling of real time data, for example for visualization purposes.

• HDA (Historical Data Access), in contrary, specifies the access to already stored data.

• AE (Alarms and Events) describes the non-cyclic, event-based exchange of alarms and events.

• Data eXchange is a specification from 2002 which regulates the direct communication between two OPC servers

For this Master’s Thesis it was made use both of the DA specification for the main purpose of communication as well as the AE specification in order to display and log round-trip times. Unfortunately, the promising Data eXchange specification is almost inexistent in practice and could therefore not be used in our thesis. The underlying technique to exchange data is the component object model COM of Microsoft Windows, therefore OPC can only run on Windows operating systems

[4]. A new generation of OPC specifications recently published is called OPC Unified Architecture (OPC UA) and is independent of COM, thus being able to run on more operating systems as well as embedded devices [5].

2.2.1 OPC Data Acces

OPC DA is organized in the hierarchical structure server, group and item. Items

correspond to variables and can be read and written. Furthermore, a quality and

time stamp is provided with each of them. When reading items, the value usually

comes from the OPC server’s cache, which is updated periodically with the values

of the device (or bus, component). However, it is usually possible to force a read

directly from the device. Clients organize their items in groups, which for example

share the same access method and update rate. Each OPC server has an unique

name, some vendors even offer the operation of multiple servers for the same device.

OPC DA provides different methods to access items, first of all synchronous and

asynchronous read and write operations. More important to us, there is also a

subscription mechanism, which is commonly used by modern clients in order to

reduce communication. That is, the client group subscribes to the server which

then “pushes” values towards the client only if they changed respectively exceed a

pre-defined dead-band. The client can force an update of all these values by issuing

a refresh call, which corresponds to an asynchronous read for all items of a group

[6].

2.3 Programmable Logic Controllers

This section informs about the two controllers involved and about the controller

that has to be replaced. Please notice that we use the term controller equivalent

to programmable logic controller (PLC) throughout our Master’s Thesis.

2.3.1 Advant Controller 160 (AC160)

The AC160 series was launched in 1997 to meet high speed requirements in turbine control. To this day its outstanding performance is needed for fast closed loop control (CLC). For our work, we were provided with a rack RF616 for the physical mounting of the controller parts. The rack also delivers power to each device and includes the BIOB Backplane Input/Output Bus which, among other tasks, processes the communication between the processor module and the communication interface. The tests in this Master’s Thesis were done with processor modules of the type PM665 (containing a Motorola MPC8240 processor) and the AF100 communication interface CI631, both supporting redundancy [7]. To program the processor module, its built-in EIA-232 interface was connected to the engineering PC.

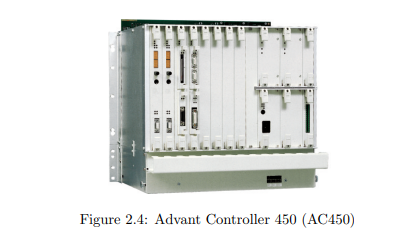

2.3.2 Advant Controller 450 (AC450)

AC450 is the controller to be replaced by the new generation. Its processor module

is built up around a Motorola 68040 microprocessor running at 25 MHz [8]. While its

performance is quite limited, AC450 also lacks of modern communication interfaces

and standards like Ethernet, which become more and more important.

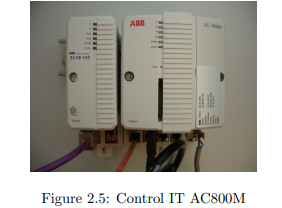

2.3.3 Control IT AC800M

Control IT AC800M is the most current controller series used within all of ABB,

introduced in 2001 [9]. It strikes with its small outline and offers modern communication interfaces. For our tests we were provided with a processor module

PM864A which contains a Motorola MPC862 microprocessor running at 96 MHz

[10]. In addition to two EIA-232 interfaces, the processor module of AC800M offers

two built-in 10 Mbit/s standard Ethernet ports, used for instance to connect to the

engineering computer.

The communication interface CI854A is a sophisticated device to establish

PROFIBUS communication. The device even offers an own web interface which

allows e.g. the surveillance of the cycle time. The device is directly coupled to the processor module via the Communication Extension Bus (CEX) [11]. At this point of time, CI854A can only act as a PROFIBUS master, but not as slave. As a consequence, communication partners must be slaves.

2.4 Bus and Network Communication

This section describes the different communication approaches used in our system

2.4.1 Advant Fieldbus 100 (AF100)

AF100 is a high performance fieldbus system with time synchronization and the most popular fieldbus used within ABB,

common to almost all platforms. Although the name Advant Fieldbus 100 is ABB proprietary, it complies to IEC standard

61375-3 as well as US-standard IEEE 1473 and is widely used in railways under the name of MVB. AF100 works over tw

isted pair, coaxial and optical media at a rate of 1.5 Mbit/s. For our system we made use of the first method only. Bus ma

ster responsibility is shared by all communication interfaces with administrator

Diplomarbeit ABB Schweiz AG

Power Systems / Power Generation

Industrielle Netzwerke Leistung – Verfügbarkeit – Zuverlässigkeit

Es sollen die bestehenden Strukturen von industriellen Netzwerken und Bussystemen für die Kraftwerksautomation basierend auf dem ABB Leitsystem 800xA analysiert werden. Dabei sollen verschiedene Fragestellungen in den Bereichen Verfügbarkeit, Leistung und Sicherheit bearbeitet werden.

Das ABB Control-System welches zur Steuerung von Hochleistungs-Gasturbinen eingesetzt wird, soll mit den neuesten Technologien punkto offener Schnittstellen, Anbindung an TCP/IP Netzwerke und Unterstützung von Device Management Tools etc. ausgerüstet werden. Hierzu soll der bestehende „Kopf-Rechner“ Advant Controller 450 durch einen Controller der neuesten Generation, einen AC800 M Controller ersetzt werden.

Die Aufgabe besteht darin, den AC800 M Controller an einen Advant Controller 160 über das bestehende Interface AF100 OPC Server anzukoppeln. Es ist eine Lösung zu erarbeiten, welche zyklischen Datenaustausch des AC800 M Controllers mit dem AC160 Controller unter Einhaltung des geforderten Datendurchsatzes, der Verfügbarkeit und der Zuverlässigkeit ermöglicht. Dabei sind die zurzeit verfügbaren Produkte und Technologien der Plattform zu nutzen.

Die Bearbeitung der oben aufgeführten Fragestellungen beinhaltet sowohl einen theoretischen als auch einen praktischen Teil. Dabei sollen Daten für die Leistung, Verfügbarkeit und Zuverlässigkeit der erarbeiteten Lösung theoretisch hergeleitet, sowie ein System aufgebaut werden. Am aufgebauten System soll anhand von durchgeführten Tests Verbesserungsvorschläge resp. Änderungen an der System-Architektur evaluiert werden können.

Die technischen Spezifikationen des Control-Systems sind soweit möglich einzuhalten resp. Abweichungen entsprechend zu dokumentieren.

Eine optionale Ausweitung der Aufgabenstellung besteht in folgender Leistung. Das System 800xA basiert seit der Einführung vor mehreren Jahren auf OPC. In der Vergangenheit wurden solche Systeme immer in einem eigenen Netzwerk und eigener Windows Domäne realisiert. Heutige Kundenanforderungen zielen immer häufiger darauf ab, dass sich OPC Server und OPC Client in unterschiedlichen Netzwerken resp. Domänen befinden. Im Rahmen der Diplomarbeit soll geklärt werden, welche Einbussen in der Übermittlungsleistung in Kauf genommen werden müssen, wenn Server und Client in unterschiedlichen Domänen liegen resp. welche Massnahmen ergriffen werden können, damit die Leistungseinbussen möglichst gering bleiben.

.png)

.png)

.png)