REF 541, REF 543 and REF 545 Feeder terminals

ABB REF 541/543/545 Feeder Terminal Technical Summary

Introduction

This document provides a comprehensive summary of the technical characteristics, functions, and applications of the ABB REF 541, REF 543, and REF 545 series of feeder terminals. These terminals are advanced devices designed for medium voltage networks, integrating protection, control, measurement, and supervision functions, and are a key component of the ABB Substation Automation system. The core content of this document is extracted from the official technical manual (1MRS 750443-MBG).

Core Functionality & Design

The REF 54 series feeder terminals integrate a wide range of functions into a single unit, designed to adapt to various switchgear configurations, including single busbar, double busbar, and duplex systems.

Multifunction Integration: The device integrates functions such as protection, control, measurement, communication, power quality analysis, and condition monitoring.

Model Differences: The main difference between the REF 541, REF 543, and REF 545 models is the number of available digital input and output (I/O) points.

Programmable Logic: It features powerful built-in PLC functionality compliant with the IEC 61131-3 standard, allowing users to perform flexible logic programming via the CAP 505 engineering tools to implement interlocking and sequential control required for substation automation.

Human-Machine Interface (MMI): Equipped with a large graphical display, which can be a fixed panel or an external module, for displaying user-customizable MIMIC single-line diagrams, measurement values, events, and alarm information.

Protection Functions

Protection is the core of the REF 54 terminal. It uses independent protection function blocks and supports both conventional instrument transformers and modern sensors (like Rogowski coils and voltage sensors).

Overcurrent and Earth-Fault Protection:

Three-Phase Non-Directional Overcurrent Protection: Provides multi-stage protection, including low-set (NOC3Low, 51), high-set (NOC3High, 50/51), and instantaneous (NOC3Inst, 50) stages. The low-set start current range is

0.10...5.00 x In.Three-Phase Directional Overcurrent Protection: Also offers low-set (DOC6Low, 67), high-set (DOC6High, 67), and instantaneous (DOC6Inst, 67) stages.

Earth-Fault Protection: Includes non-directional (NEF1 series) and directional (DEF2 series) protection. Directional earth-fault protection uses residual voltage for polarization and supports various criteria such as

loSin(φ)andloCos(φ).Voltage Protection:

Residual Overvoltage Protection: (ROV1Low, ROV1High, 59N)

Three-Phase Overvoltage Protection: (OV3Low, OV3High, 59)

Three-Phase Undervoltage Protection: (UV3Low, UV3High, 27)

Thermal Overload Protection:

Provides specialized thermal overload protection models for cables (TOL3Cab, 49F) and devices (TOL3Dev, 49M/G/T). The device protection model considers complex factors such as starting current, cooling time constant, and ambient temperature.

Other Key Protections:

Auto-Reclosing (AR5Func, 79): Supports up to 5 reclosing shots.

Synchro-check (SCVCSt1/2, 25): Used for checking synchronization conditions before closing a line.

Circuit Breaker Failure Protection (CBFP, 62BF)

Under/Overfrequency Protection (Freq1St1...5, 81U/O): Provides 5 stages of frequency protection.

Inrush Detection (Inrush3, 68): Based on the 2nd harmonic principle to prevent mal-operation due to transformer magnetizing inrush current.

Control & Measurement

Control Functions: Supports local and remote control of switching devices like circuit breakers and disconnectors. The status of switches is intuitively displayed on the MMI via a configurable MIMIC diagram.

Measurement Functions: Capable of accurately measuring three-phase currents, voltages, residual current and voltage, frequency, power factor, active power, reactive power, and energy. Measured values can be used for display, logic programming, and reporting to higher-level systems.

Power Quality & Condition Monitoring

Power Quality:

Can measure Total Harmonic Distortion (THD) of voltage and current, and Total Demand Distortion (TDD) of current.

Can analyze individual harmonics up to the 13th order.

Data collection and analysis comply with standards such as EN 50160 and IEC 61000-4-7.

Condition Monitoring:

Circuit Breaker Monitoring: Includes electrical wear (CMBWEAR1), operation time counting (CMTIME1), trip/close coil circuit supervision (CMTCS1/2), etc.

Self-Supervision: Comprehensive internal self-diagnostic functions continuously monitor the operational status of hardware and software.

Temperature and Voltage Monitoring: Monitors the internal temperature of the device (over-temperature alarm at

+78°C) and the auxiliary power supply voltage.

Hardware & I/O

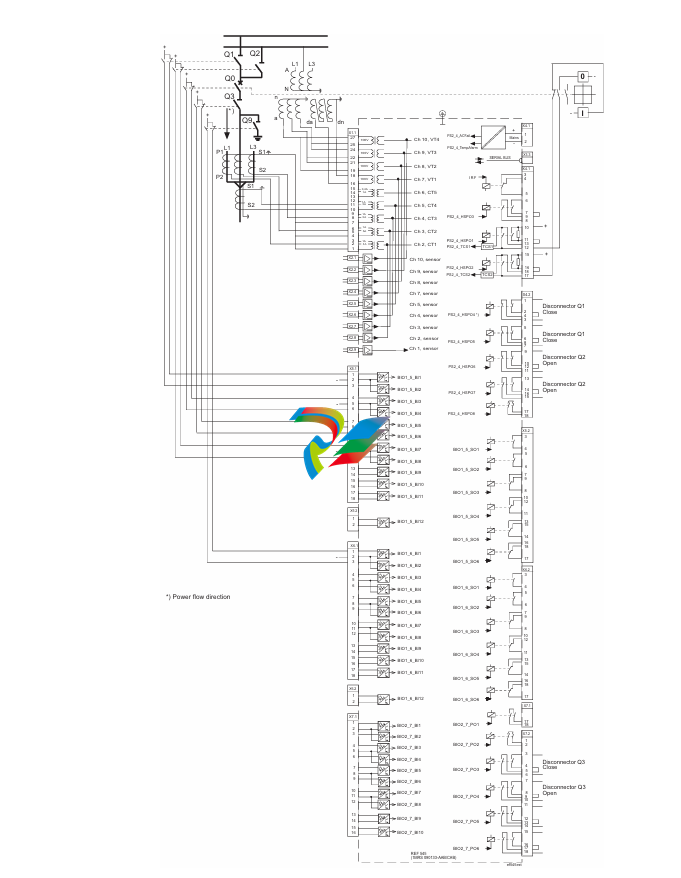

Analog Inputs: 9 or 10 analog channels depending on the configuration, supporting traditional CT/VT or sensor inputs.

Digital Inputs: REF 541/543/545 provide 15/25/34 galvanically isolated digital inputs, respectively.

Digital Outputs: A combination of high-speed power outputs (HSPO), power outputs (PO), and signal outputs (SO). For example, the REF 543 provides 9 double-pole power outputs.

RTD/Analog Module: The REF 541 and REF 543 can be optionally equipped with an RTD/analog module, providing 8 universal inputs for measuring temperature, DC voltage/current, and four 0-20mA analog outputs.

.png)

.png)

.png)