ABB Safety Triguard 2 TMR Safety Products

• Provides fault isolation

• Co-ordinate signal processing

• Provides diagnostics • Provides on-line to off-line switching (hot repair)

• Provides data validation routines

• Provides data to the processor

• Provides latent fault detection

A fault in one signal path cannot be passed to another. I/O modules can

be fitted in any of the 10 slots in any chassis. “Hot Repair” is a customer

configurable option on a per module basis. All modules are “keyed” to prevent

improper installation

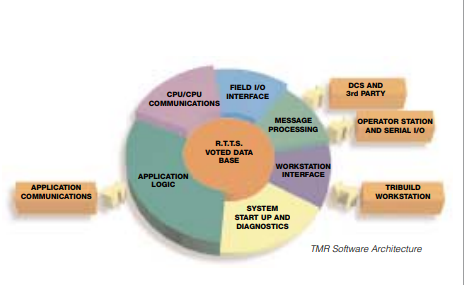

Software

The Triguard SC300E supports three main application software packages, all are Windows compatible:

• TriBuildTM for developing and programming application logic

• TriCommandTM a display and control system workstation (WONDERWARE©)

• TriLogTM simple PC based alarm/event logger

The TriBuild Workstation is connected to a Triguard SC300E TMR system via the communications module

. TriBuild provides on and off-line configuration, programming, documentation and testing functions. Progr

amming uses both conventional ladder logic displays, function block programming and structured networks.

TriBuildTM software provides

• A comprehensive library of programming elements, eg logic, arithmetic, data conversion, timers, counters, block elements, bit shift, comparators, mid value select, NooM voting blocks

• An environment for users to develop special functions, function blocks, custom programs for

TriBuildTM

TriBuild is an easy to use, menu driven, software package running under Windows NTTM. It is used for the creation of system application logic of the Triguard SC300E control system. Key features of TriBuild:

• System Configurator – easy guide for system build

• Ladder Annotator – adds notes to the ladder logic

• Network Editor – on-line/off-line editing of logic functions

• On-Line Help – reduces need to refer to printed manual

• Ladder Simulator – allows testing during program development

• Built-In Compiler – for high level user functions

• Password Protection – selective access and protection

• Function Block Programming – using IEC 1131 standard function as applicable to safety These can be developed quickly and effectively with the assistance of search and replace, cut and paste and a standard library of logic symbols and programming functions. Completed control programs can be loaded into a Triguard SC300E system and the execution of the control program can be monitored on-line with the TriBuild workstation. advanced fault tolerant control applications

• Application specific control functions, eg auto-test routines, gas detection calibration tables, advanced control

• System interrogation

• Control and user changes with date and time

• Off-line configuration, simulation and applications testing of the control programs

TriBuild provides a secure environment to make program changes on-line and without interrupting the normal process operations. TriCommandTM TriCommand is a PC-based operator workstation, utilising Wonderware’s InTouchTM products. TriCommand

provides real time system control and monitoring facilities. It can operate as part of a Triguard SC300E system in a single station configuration or as multiple TriCommand stations for distributed applications. TriCommand workstations can be connected to a Triguard SC300E system via peer to peer, single, or dual serial communication links, networked via single or dual redundant LANs. TriCommand is Windows NTTM compliant. Standard off-the-shelf hardware makes customer ownership and support easy to achieve. TriCommand workstations may be installed in the control room for operator display and control or at a remote location where there may be a need for local information and control. TriCommand allows a user to start small and expand into an integrated environment providing a single seamless network. Expansion is simple and cost effective. Key features of TriCommand:

• A real time database of up to 32,000

points that can be mapped to field

or virtual I/O points

• Dynamic Data Exchange (DDE)

allowing TriCommand to pass data

to other Windows applications, eg

ExcelTM

• Supports a comprehensive range of

industry standard protocols, such as

TCP/IP via the DDE server library

• Can display an almost unlimited

number of mimic pages

• Extensive alarm handling

capabilities, including accept, reset,

cross functions (for multiple

systems), zone hierarchy, first out,

status, prioritising, displays,

summaries

• Data logging, data archiving, data

trending

• Event status, event history, event

display, event printing

• Fault diagnostics – communication,

systems

• Advanced control – digital, analogue

• Multi-level security access

The Graphical User Interface for

operators, engineers and managers is

a multiple Windows display on a

single screen. Displays can however

be locked on full screen making the

Windows feature unavailable.

Operators can choose different means

of navigating and interacting with the

system, from full keyboard to a

restricted pushbutton selection pad.

Engineers can develop graphical

displays using a powerful display

builder which can be tailored to the

.png)

.png)

.png)